Aim

- To test the failure pressure of regular T8 FTC.

- To test the failure pressure of glass strapping tape reinforced

T8 FTC.

Experiment Setup

The standard hydrostatic burst test procedure was used to carry

out these tests. (See above)

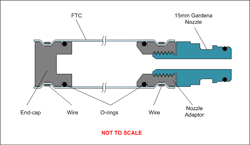

The FTC used for these tests only has an

average wall thickness of 0.36mm. We made an end-cap out of some

PVC we had on hand and the nozzle is

based on a 15 mm Gardena nozzle. The one we

bought from the local hardware store came

with an outside thread. We machined an

adaptor with a matching thread that fits

snugly inside the FTC. We then epoxied the

nozzle inside the adaptor. The seal for the

end-cap and nozzle is provided by an o-ring

that sits against the FTC. Just behind the

o-ring is a groove that allows us to shrink

the FTC into it to hold the end-cap and

nozzle in place. We copied this technique

from

Urie's water rockets.

To secure the end-cap and nozzle we wrapped a

couple of loops of thin fencing wire around

the FTC just over the groove. We then apply

heat from a heat gun to the FTC while

applying tensile stress to the wire. This

allows the wire to deform the FTC into the

groove. We then let it cool down and twist

the wire closed. For the first test we used

a 1 foot length of the FTC and secured the

end-cap and nozzle at either end.

Results

Test #1

|

FTC just after the 190psi burst test. |

|

Detail showing where the wire sits in the

groove at the nozzle end. |

|

Burst location. |

We hydrostatically tested the FTC to

190 psi before the FTC split. The end-cap and nozzle held and

that there were no leaks.

Test #2

We hydrostatically tested a 1

foot length of FTC wrapped with one layer of fiber

glass strapping tape. We also added a number

of extra wraps of the tape around each end

right near the o-rings to help with the

seal.

|

FTC test with glass fiber strapping tape

reinforcement. |

|

At 230psi the end cap came out. The flare at

the end of the FTC was due to the heating

process and normally would be removed for a real

rocket. |

As we reached

230 psi the end-cap flew out of the FTC. It

looks like the groove in the end-cap was not

deep enough and the wire probably loosened

where it was twisted. This allowed the

end-cap to slide past the wire.

There was no

damage done. The single layer of tape added 7grams to the

1 foot length of FTC. |