|

Overview

This procedure is used to measure the dimensions of a

pressure vessel. Because pressure vessels can stretch while

pressurised the dimensions change. The change in dimensions is

important for design purposes. |

Caution

Due to pressures involved, this experiment should be carried

out behind a safety barrier.

Equipment

Procedure A - Unpressurised

This procedure measures the height and circumference of the

pressure vessel in the unpressurised state. This information is

useful for example when matching bottles to see if they will fit

into one another.

Height

- Stand the bottle on its base.

- Balance a set square on the top of the bottle thread

so that an accurate measurement to the base can be made

using a ruler.

- Record the measurement.

Circumference and Diameter

Most bottles have a number of protrusions around the

circumference of the bottle. Knowing the dimensions of these

helps in calculating how bottles will fit together.

It can be difficult to measure the diameter of the bottle

directly because they are soft and often slightly distorted. It

is easier to measure the circumference and then convert that

into a diameter using the formula d = circumference / pi.

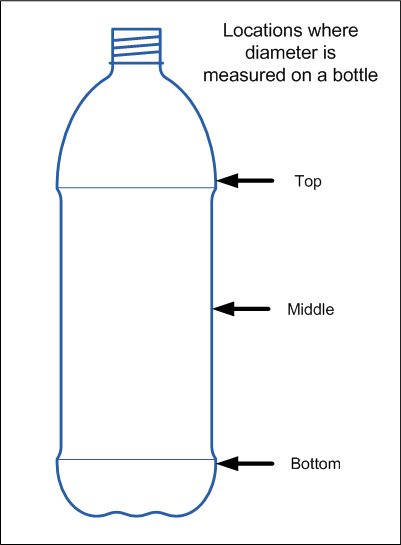

Often bottles will have a cylindrical section that is

slightly narrower than the top and bottom sections of the

bottle. See diagram 1.

The middle measurement is useful for splicing bottles

together, and the top and bottom measurements are useful for

determining the rocket's cross sectional area when calculating

drag, or fitting the rocket between launcher guide rails.

- Cut out a 2 cm wide strip of paper with at least one

straight edge.

- Wrap the paper around the bottle so that it sits snugly

up against it and so the straight edges meet.

- Make a marking on the paper where the end finishes.

- Remove the paper and measure the length between the

marks.

- Record this as the circumference.

- Repeat the above steps for the top, middle and bottom

sections of the bottle.

Procedure B - Pressurised

This procedure measures the change in height and change in

circumference of the pressure vessel when pressurised. This

information is useful for understanding how much the rocket will

stretch under pressure and how it may effect any fittings fitted

to the rocket or the launcher.

Height Change

- Completely fill the pressure vessel with water.

- Place the pressure vessel on the

Volume and dimension measuring stand.

- Attach the needle to the top of the bottle. (see

diagram) and make sure it lines up with the ruler on the

side of the stand.

- Record the reading on the ruler.

- Connect the air supply and slowly increase the

pressure to the desired level.

NOTE: You should have performed the

burst test on

the bottle prior to this test in order to not exceed the

burst pressure.

- When the pressure reaches the desired value take the

reading on the ruler. The difference between the two

measurements is the height increase at that particular

pressure.

- Depressurise the bottle.

Circumference Change

- Completely fill the pressure vessel with water.

- Place the pressure vessel on the

Volume and dimension measuring stand.

- Attach one end of the measurement strip to the

desired section of the bottle with a piece of tape. The

middle section of the bottle is the most often useful.

- Wrap the strip around the bottle one full

circumference.

- Hang the weight from the other end of the strip.

- Either record the reading on the strip where it

starts the overlap, or draw a line on the strip.

- Connect the air supply and slowly increase the

pressure to the desired level.

NOTE: You should have performed the

burst test on

the bottle prior to this test in order to not exceed the

burst pressure.

- When the pressure reaches the desired value take the

reading on the strip or make a second line. The difference between the two

measurements is the circumference increase at that particular

pressure.

- Depressurise the bottle.

Notes

- Appropriate protection should be worn when performing

this experiment as it may involve getting close to the

bottle under pressure.

|