|

|

| WATER ROCKET CONSTRUCTION - BASIC |

|

|

So you want to build one... The following instructions describe how to build a

simple single stage water rocket capable of flights to altitudes

of around 60 – 80m. (~180 – 250 feet). For simplicity this rocket does

not use a parachute.

For more advanced construction tutorials go to the

Construction Index.

Warning

When cutting PET

bottles with a knife, it is easy to slip and do some damage to yourself,

or the work area. Always reach for scissors first as these are easier to

control and much less dangerous. A rubber chicken is not sharp enough to

cut through plastic bottles.

Tools

You will need at least the

following tools when building the rocket and launcher but a well

equipped workshop is always useful:

- Drill and drill

bits.

- Round or half round

file

- Scissors

- Stanley knife

- Fine sandpaper

- Hacksaw or tin

snips

- Tape

|

|

|

|

| Body |

|

A typical 1.25 L bottle... about to be

transported faster than ever before. |

|

Drink the contents of the bottle and wash it out. Remove the

label, cap and the plastic ring. |

|

A complete bottle will be the fuel tank that

will also hold the pressurised gas.

Bottle Preparation

- Get a 1.25L bottle and wash it out

with dishwashing detergent to get the sticky residue out.

The shape of the bottle can play a role in the aerodynamics,

water flow within it and its center of gravity. For this reason a bottle

with straight walls, no ornate protrusions and a smoothly

tapered neck is a good choice. (Shaped Coke bottles are an

example of an unsuitable bottle)

- Remove the label.

- If the label leaves a sticky residue you can easily

remove it by using a little mineral turpentine on a cloth.

You should then wash the turpentine off with a soap and

water.

- Inspect the bottle for any kinks or

scratches. The bottle may burst at these places when

pressurised to a higher pressures.

- Measure the capacity of the bottle,

don’t necessarily believe the label. Knowing the capacity

will help you determine how much water should be put in.

That’s the end of the bottle preparation.

Storing the contents of the bottle in a

plugged up sink with a note “will drink later” is probably less

than ideal. Make sure you buy bottles with contents you will

drink. Because a bottle looks aerodynamic in the store does not

mean you will want to drink some cheap imitation lemonade. While

making rockets you will need plenty of bottles to make different

components. The best way get bottles is from your friends, that

way they feel they have contributed to the race for the lower

atmosphere. |

|

|

|

Back to Top

| Ring Fins |

|

Cut a plastic ring from a bottle. |

|

A can with an appropriate diameter and a

manila folder. |

|

Mark the can and paper. |

|

Roll the can along the edge and then divide

the length into thirds. |

|

Roll the manila folder around the can

tightly, and tape when finished. |

|

Finished fin jig. Make sure that the can and

folder sit square on the table. |

|

Slip the ring over the fin jig. |

|

Choose an appropriate strut material. We

will use slimline Venetian blinds cut to length. |

|

Align the strut along the lines on the jig,

and tape the strut to the ring. Repeat for all

struts. |

|

Slide the fin assembly off the jig. |

|

Staple and or tape the struts securely to

the ring. |

|

Reinforcing of the struts is recommended if

you are using Venetian blinds. |

|

Place the ring assembly back on the fin jig

and leave an overlap at the top. |

|

Place the main bottle body into the jig.

This helps align the body with the fins. |

|

Tape the struts to the body and then just

slide the whole thing off. |

|

|

We prefer to make ring

fins for our small rockets. This is because they are easy to

construct, are easily aligned, are very aerodynamic, and fit in

the launcher nicely.

It is very important to

align the fins as accurately as possible so that the rocket

flies straight. Before we make the fins we will create a jig

that will make the whole process easier.

Fin Alignment Jig

- Get an empty washed-out

bottle that is the same diameter as the bottle prepared earlier

and with scissors cut out a ring of material. You can experiment with the width of the

fin ring, but around 50mm is a good compromise. Making the ring

narrower, reduces the weight of the whole rocket, but also is

less effective.

- Find another bottle with

straight sides or preferably a can of food whose diameter is

about 2mm less than the ring you have just cut out. It does not

matter if it is canned carrots or soup.

- Now get a manila folder

and place the can on top of it aligning the can’s edge with the

edge of the folder. Put a mark on the can and the folder for

alignment.

- Roll the can along the

edge and place a second mark on the folder where the original

mark on the can was.

- Now divide this distance

into thirds, and accurately make 3 parallel lines on the folder

that are perpendicular to the bottom. These lines will be used

for aligning the fin struts.

- Now roll the manila

folder tightly around the can making sure that the lines are

visible on the outside and that the bottom edge of the folder is

flush with the can and sits upright when standing. Use tape to

hold the folder on the can. Leave the can in the folder as it

ensures that proper shape is maintained and provides a stable

weighted base when assembling the fin.

- The bottle ring should

fit snugly on the jig but not too tight.

The fin jig is now

finished.

Before dinner go down to

the grocery store and replace the can of food you used for the

fin jig!

Fin struts

You will need to make

some struts to hold the ring in place. These struts should be as

stiff and as light as possible. You will need three of them.

Some suggestions:

- Slim aluminium Venetian

blinds: These are lightweight and relatively sturdy, they are

very easily attached with a stapler, however, they do

have a tendency to buckle on impact. If you use these, you

should consider reinforcing them with something lightweight like

bamboo skewers.

- Rohan sent in a good suggestion as an alternative to

Venetian blinds and that is to use old tape measures. He

reinforces them with skewer sticks.

- Anti-static IC

packaging: These are very strong, light weight and relatively

indestructible. Use the ones for DIP (Dual In Line) packages.

You should be able to pick some up from a local electronics

store, perhaps for free if it is waste.

- Extruded plastic

moulding: - This tends to not be as stiff as the IC packaging and

also tends to be a bit heavier. If the moulding is

relatively wide, you may be able to just use 2 instead of 3.

- Various plastic tubing or thin

fibreglass rods are also suitable alternatives.

- Bamboo skewers ( see the

D.Y. or Clifford

rockets )

In this example we will use the Venetian blinds as they are

quite common, light weight and provide extra surface area for

the fins.

Procedure

- Cut three 300mm lengths

of the strut material.

- If you are using other materials you

may want to consider tapering the leading edge

of the strut with a knife or scissors for better aerodynamics.

- Place the ring on the

jig and hold in place with a small piece of tape.

- Place one strut along

the line drawn on the manila folder and hold it at the top with a

clothes peg or a piece of tape.

- Now tape the bottom of

the strut to the ring. This is only temporary while everything

is aligned.

- Repeat the steps above

for the remaining two struts.

- Now remove the fin assembly from the jig. This now gives you a

well aligned ring fin with parallel struts.

Design Note: We found that tape was

insufficient to survive more that a couple of impacts when using

IC packaging fin strut material so we

wired the struts to the rings. An easy way to make small holes

in the plastic is to heat a needle over a flame such as the

stove and then simply push the needle through where you want the

hole. Use a pair of pliers to hold the needle … well for obvious

reasons. Also do not try to use a sewing machine to make things

go faster as getting the flame to sewing machine needle it is a

little tricky.

Burning the hole through

as opposed to drilling it, makes sure that the material does not

develop tiny cracks around the edge of the hole that could make

it fail on impact.

After you have made all

the holes, use some wire to hold it together. This

gives a very strong bond. You can now remove the tape that was

used when aligning everything.

- Now staple or tape the struts to the ring for a secure

bond.

- You can reinforce each strut with a bamboo skewer simply

by taping it on. We were surprised at how well this works

without adding too much weight. We have never had a buckled

strut since.

- Place the ring assembly back on the fin jig but leave

the ends of the struts showing over the top.

- Put the rocket body (bottle) upside down into the jig.

This allows you to align and hold the bottle in place while

you are attaching the struts.

- Tape the struts to the body of the rocket and then

simply slide the rocket off.

And you are done with the fins. |

|

|

|

Back to Top

| Flat Fins |

|

A cardboard fin template |

|

Corriflute cut out to shape |

|

Small holes drilled along the edge to be

joined. |

|

Trim the left over plastic after drilling. |

|

Lightly sand the area to be glued. |

|

Lightly sand the bottle where the fins are

to be attached. |

|

Fin alignment jig sitting on top of the

rocket. |

|

Run a bead of PL Premium along the edge

making sure it penetrates up to the holes. |

|

Place the fin on the bottle. |

|

Run a bead of glue on the outside to cover

the holes and create fillet. |

|

Completed fin set that can be fitted to

different rockets. |

|

|

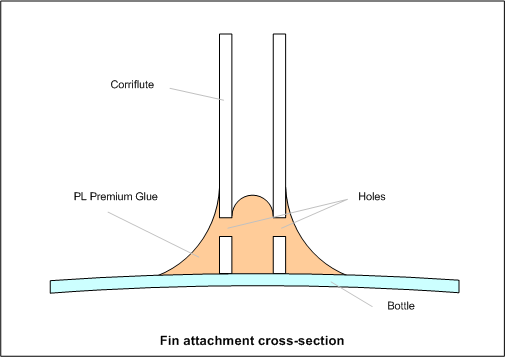

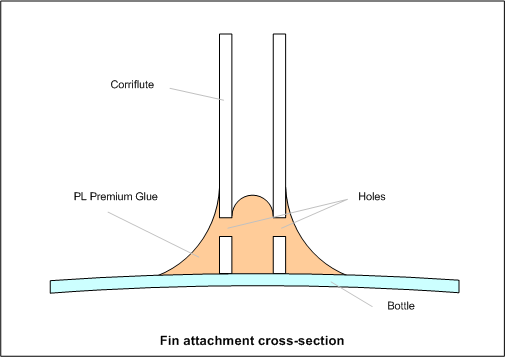

For larger rockets, ring fins are not always practical and so the more

conventional flat fins should be used.

Here we are making the fins from Corriflute (Correx)

corrugated plastic that

signs are commonly made from. These are durable, lightweight,

water proof, nice and flat and above all inexpensive.

One of the most common problems with Corriflute is that it is

made from polypropylene and so is very difficult to glue

with any great amount of strength. Most glues will not stick to

it well . The procedure described below

will ensure a good strong bond to the bottle. In this procedure

we attach the fins to a section of a bottle that can slide over

the top of another bottle which allows it to be reused on other

rockets, but the fins can be glued directly to the rocket body.

Fins need to be attached well because large G-forces and drag

could brake them off or if the rocket lands on them during

descent.

Procedure

- Make a cardboard template of the fin shape you would like to

use. Make sure that it contours the bottle as closely as

possible. As far as the fin shape goes that is up to you.

The main thing to remember about fins is that they need to

be stiff, as far back as possible and lightweight. Always

remember that fins are there to add

rocket stability and so ultimately the surface area of

the fins is important.

- Trace this template onto the

Corriflute material so that the channels

run as close to perpendicular to the

bottle as possible. On curved surfaces

an

approximation to perpendicular is good

enough.

- Cut the fins out with a sharp craft

knife.

- Now using a 2mm drill bit, drill a hole all the way

through the fin in each channel. The holes should be 3 to 5

mm from the joining edge. If you are using thinner

Corriflute, adjust the spacing accordingly. (See photo)

- Clean up the holes with a sharp knife, cutting off any

bits left over after the drilling.

- Clean the surfaces around the holes and lightly sand them.

- Now lightly sand the bottle where you are

going to glue the fins. The number of

fins you use is again up to you but anything above 4 is of

little benefit. 3 or 4 fins are the most common. A good way

to measure the distances around the bottle is to wrap it

with a piece of paper and then use a ruler to divide it up

into thirds or quarters and mark the positions. Put the

paper back on the bottle and transfer the marks to the

bottle.

- For the next step we use a simple alignment jig to keep the fins

pointing in the correct direction. You can use a

length of plastic, wood or aluminium angle and simply rest

it on top of the rocket. It will naturally align itself with the axis of the

rocket. We then attach a pair of smaller angle brackets

to it in order to support the fin from either side. This

also allows the aligning jig to keep clear of the glue

fillets. You can tape the jig to the bottle to secure it

further. We wedge the rocket between stacks of heavy books

to keep the rocket steady on the table.

- Run a bead of PL premium into each of

channels so that it penetrates all the way up to the holes.

NOTE: Anytime you use PL premium you should use

gloves and always work in a well ventilated area.

- Place the fin onto the bottle and

align using the jig.

- Now run a bead of PL on the outside between the bottle

and the fin. You can use a gloved finger

to make a nice

fillet between the bottle and fin but

make sure a healthy thickness of glue remains over the

holes. Do this from both sides.

- Let the glue cure overnight before

doing the next fin.

You now have a strong bond between

the fin and the bottle. The holes allow

the glue on the inside and outside to

merge creating little fingers that keep

the Corriflute in place mechanically

even if the adhesion fails in parts.

|

|

|

|

Back to Top

| Gardena Nozzle |

|

A typical tap garden hose attachment. |

|

Make sure it is of reasonable quality with a

good o-ring. |

|

Remove the thread leaving a shoulder. |

|

Remove the plastic seal from the cap. |

|

Cut a hole in the cap and the seal. |

|

The garden hose attachment should fit

snugly in the cap. |

|

Place the seal against the hose fitting. |

|

A completed nozzle. Notice the tight fit

between the hose fitting and cap. |

|

Nozzle fitted to the bottle. |

|

|

|

|

Back to Top

| Nosecone |

|

Nosecone made from medium density foam.

Shaped with a knife and smoothed with sand

paper. |

|

Same material as above. Attached to the

bottle using a ring of plastic material. |

|

Nosecone made from the top of another

bottle. This one is not designed for impact. |

|

Same as above but a different shape. Both

are designed to hold a parachute. |

|

A kids ball with whistles. |

|

Cutting off the front makes for a very good

strong nosecone. |

|

|

For rockets without a parachute, the

nosecone is perhaps the trickiest to get right so that it

survives multiple landings. You can make it fairly lightweight

and smooth, but it needs to be strong enough to withstand

impact. If it is too rigid it may damage the bottle or the

person it lands on. Make sure that the

nosecone is not too light as in

order to maintain rocket stability.

Experiment with using

different density foams, and the cut off sections from the tops

of PET bottles. Some high density foams are easy to cut with a Stanley knife,

but can be hard to get smooth. You can use coarse sandpaper to

make them more streamlined. A disk sander also works well for

shaping the nosecone.

The way you attach your nosecone will depend on the design that

you use, but typically you can use a ring of plastic from a

bottle to make the transition from the bottle to the nosecone.

We recommend using only tape to attach it as it will have a bit

of give when the rocket impacts, and makes it easy to repair if

needed. Pictures on the left show a variety of nosecone designs we have

used. Some worked better than others. Parachutes:

A full tutorial on how to make a

side deployment parachute mechanism is now available.

For lots more information and details on how to add a

various recovery system such as a parachute go to the:

Recovery Guide. |

|

|

|

Back to Top

Back to Top

Advanced Construction Techniques >>

|