|

Which Nozzle?

This article describes the various aspects of water rocket nozzles. Choosing the right nozzle for your

water rocket depends on a number of factors, and may change

depending on what you are trying to achieve with a particular

flight.

When choosing a nozzle for any water rocket you need to consider the

following:

- Desired flight profile. For example slow vs. fast launch.

- Minimum lift-off thrust requirement depending on the weight of

the rocket.

- Launcher type available as not all nozzles fit all launchers.

|

There are three important aspects to any nozzle:

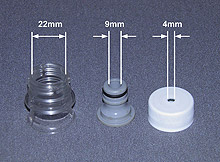

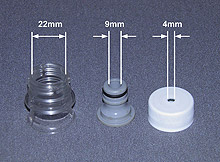

1. Nozzle Size

The nozzle size in water rockets is measured by the

narrowest internal diameter (throat) in the nozzle and is often

given in mm. The internal diameter is important because it directly

relates to the mass flow rate out of the nozzle. The larger the nozzle

the higher the thrust for a given pressure. Note that the length of the

nozzle typically isn't important although there will be slight

performance differences with variations in the length. Internally

nozzles are typically cylindrical because water is incompressible and

hence does not benefit from a

DeLaval nozzle the same way

combustion rockets do. Discussion of DeLaval or Convergent-Divergent

(CD) nozzles in water rockets is a topic of its own and is left for a

separate article. |

|

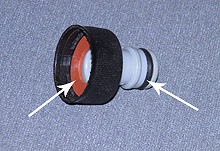

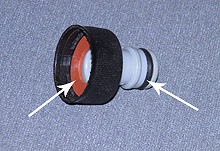

2. Retention Method

In general most nozzles are also used to hold

down the rocket on the pad. Different types of nozzles have different

retention mechanisms and as a result each will use a particular launcher

design. Some nozzles lend themselves to several different launcher

release head designs. Refer to the

Launcher article for more information

on launcher release mechanisms.

The arrows in the image show where the nozzle is held down by the

launcher. |

|

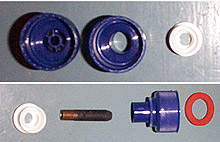

3. Seals

A nozzle may have 1 or 2 seals depending on the nozzle type. The

first seal goes between the bottle and nozzle while the second seal is

between the nozzle and the launcher. When using the bottle neck as the

nozzle then you only need one seal and that is between the nozzle and

the launcher.

Seals prevent water and air escaping through the

nozzle-launcher interface. There are various seal designs depending on

the nozzle type and release head combination. |

|

What nozzles are available?

There are several different types of nozzles commonly in use:

| Image |

Type |

Description |

|

Full-bore |

This is the standard neck opening of a PET bottle used for

most water rockets.

The diameter is ~22mm. Sometimes these nozzles are

attached to other rockets such as those made from FTC. These are by far

the simplest nozzles to make and use.

|

|

Gardena |

Gardena nozzles are made from garden hose quick connectors.

The garden industry typically refers to their measurement by their

external diameter of 12mm whereas the water rocket community refers to

the same quick connectors by their internal diameter of 9mm.

Normal tap

quick connector adaptors are unsuitable for use directly

on most PET bottles as the threads don't match. Some work is required to

make a Gardena nozzle.

See the Gardena

Nozzle tutorial for more details. |

|

Maxi-Flo |

This nozzle is similar to the Gardena quick connector, but

with a larger diameter. The internal diameter is 15mm. The garden industry refers

to these again by their external diameter of 18mm.

|

|

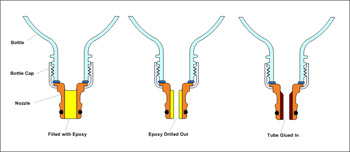

Cap |

This nozzle is simply a

standard bottle cap with a hole drilled in it. AntiGravity

Research uses these with their unique launcher.

|

|

Sport-cap |

These nozzles are made from the cap on sports drinks.

These are not commonly in use.

The tutorial on how to make the sport cap nozzle is here:

|

|

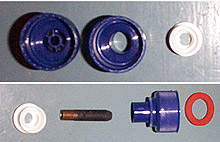

Custom |

Custom nozzles can be made from any material, any profile and

any size, however, these are less common and typically designed for

specific rockets and launchers. Here are some other examples of custom

nozzles:

|

|

T-nozzle |

T-nozzles are a special nozzle that changes the internal

diameter. The nozzle has a larger diameter while it is on the launch

tube to maximize the piston effect, but once it leaves the launch tube

it reduces the diameter for a longer sustained burn. The T-Nozzles concept can be used

with various nozzles diameters.

Here are some examples of how to make t-nozzles:

|

Large Nozzles vs. Small Nozzles

Many people ask whether a larger or a smaller nozzle is better,

however, nozzle size must be chosen in combination with launch pressure

and lift-off weight. The rocket must achieve at least a minimum

acceleration to reach a high enough velocity by the time it leaves the

guide rail or launch tube so the fins can help stabilise the rocket.

For small light rockets you have a choice between small or large

nozzles, while for large or heavy rockets you typically need proportionally larger nozzles.

Regardless of nozzle size, accelerations well

below 3G are likely to result in the rocket tipping over soon after

launch especially during cross wind conditions. As a rule-of-thumb you

should try to aim for accelerations of 3G or higher for most launches.

You can use one of the on-line water rocket simulators

to calculate the predicted acceleration of your rocket for a given

nozzle size.

Once you determine that your rocket will achieve at least the minimum

acceleration with a particular nozzle, water fill and pressure, you then

often have a choice at how much faster you want the rocket to

accelerate.

While keeping the weight and launch pressure the same, you can change

the acceleration by changing the size of the nozzle. Small light rockets

with large nozzles can easily reach accelerations of 150G+. For Example:

A 2L rocket that weighs 150grams, uses a 22mm full-bore nozzle, filled

with 800mL of water and pressurised to 130psi will reach a maximum

acceleration of ~155G.

High and low accelerations have their advantages and disadvantages and which one you

choose depends on what you are trying to achieve.

| Acceleration |

Advantages |

Disadvantages |

| High |

- Allows your rocket to reach a stable speed sooner

reducing the need for longer guide rails.

- The rocket will generally reach a higher altitude but is

dependant on a number of factors.

- Generally the launcher

does not require a separate guide rail if a launch tube is used.

|

- More stress put on components. Components need to be

secured against the acceleration force,

- Aerodynamics becomes more important as

drag is proportional to the square of the velocity.

- Difficult to film

and photograph. The rocket moves very quickly during launch.

|

| Low |

- Less stress put on components during launch.

- Easy to film

and photograph

- Suitable for upper stages in multi-stage rockets to

keep peak velocity down.

|

- Generally need a guide rail on the launcher

- More susceptible to cross

wind during early part of flight

- Single stage rocket may not fly nearly as high as a high

acceleration rocket, but again that is dependant on a number

of factors.

|

Practical Tips

- Removable Nozzles - If you are adding a restricted nozzle to your rocket then it is a

good idea to make it removable. That way you can swap it between rockets

as needed and you can try flying the same rocket with different nozzles.

- Nozzle Weight - Keep your nozzle weight to a minimum. Using a

heavy nozzle not only means you will achieve lower altitude, but

will make your rocket less stable because it moves the center of

gravity further back down the rocket.

- Nozzle Alignment - Make sure your nozzle is well aligned. If

you are using a removable nozzle, or are gluing your nozzle

permanently, then it is important that you make sure your nozzle

directs the thrust down the centerline of your rocket and the thrust

vector goes through the rocket's center of gravity. If the nozzle is

misaligned you may end up with a rocket that flies in an arc rather

than straight up.

One way test your nozzle alignment is to get a long (~1m) dowel, rod

or tube that fits tightly into your nozzle. Stand the rocket up on

it's nosecone so the dowel is sticking up. This way the weight of

the dowel doesn't affect the nozzle. It should be fairly obvious if

the dowel is leaning to one side indicating the nozzle is

misaligned.

|