|

Introduction

This mechanism was developed to provide automatic staging of multi-stage water rockets.

This mechanism will release a sustainer with a standard 9mm Gardena nozzle when

the booster stops producing thrust.

The key design criteria for this stager was simple construction from commonly available materials, that require no special tools.

Total weight of prototype: 40 grams. |

How It Works

For illustrative purposes the diagrams below have been simplified. Click on the

diagrams for a larger version.

|

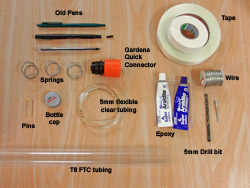

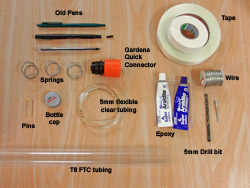

This is a photograph showing the actual components used to make the staging mechanism.

Components include: Old pens, Gardena quick connector, 3 springs from Gardena quick connectors, bottle cap, sewing pins, 5mm clear plastic tubing, T8-FTC, tape, solid core wire and Epoxy glue. |

|

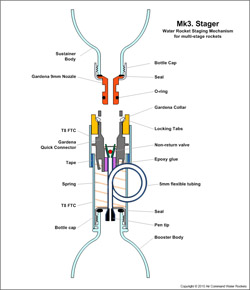

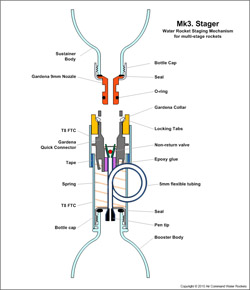

Components The operation of the

Gardena quick connector is reversed in this design in that it is the inner part of the quick connector that moves rather than the collar. The spring

is moved from the inside of the collar and placed on the

outside to force the quick connector open.

The body of the stager is made from a section of FTC that is permanently attached to the booster. The body is also permanently attached to the collar via a second piece of FTC.

The flexible tubing allows the inner part of the Gardena mechanism to freely move in relation to the booster.

|

|

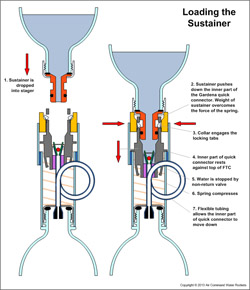

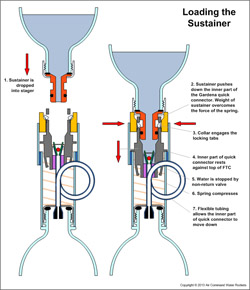

Loading The Sustainer When the sustainer's nozzle is

placed into the stager, the sustainer's weight forces the inner part of the

quick connector down into the locked position gripping the sustainer nozzle. The nozzle locking is purely

achieved by weight and is independent of internal pressure.

While the rocket is on the pad the ground provides an opposing force to keep the mechanism locked. |

|

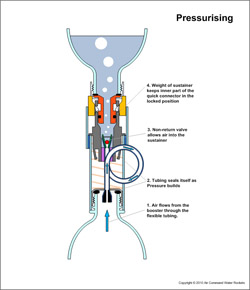

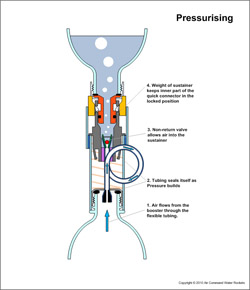

Pressurising Pressurising the booster allows air to flow through the clear tubing into the sustainer, with the non-return valve in the Gardena quick connector preventing water and air from flowing back into the booster. Since the stager locking mechanism is pressure independent, pressurising the booster does not cause the sustainer to fly off.

The clear tubing is self sealing. As pressure builds in the booster and sustainer, the clear tubing is pressed against the holes because it is widened by the inserted pen tips. |

|

Launch When the rocket launches acceleration and weight continues to keep the

mechanism down and locked.

During acceleration the sustainer is supported by the FTC body, as the inner part of the quick connector rests against the top of it. The bottom part of the FTC body rests against the booster's bottle flange. |

|

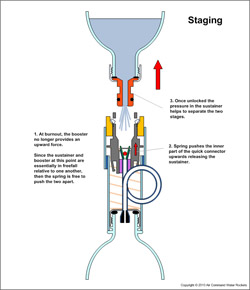

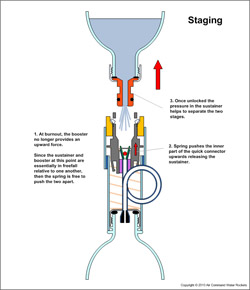

Staging As the booster runs out of thrust the only forces acting on the staging mechanism are the force of the stager spring and air drag. Since the sustainer and booster are essentially in freefall relative to one another, the spring is free to push the two stages apart. As it does so, it also unlocks the sustainer's nozzle, and the pressure inside the sustainer helps to push the two stages apart achieving staging. |

Construction

Details

See

the

Mk 3

Stager

Construction

Tutorial

for

step-by-step

instructions

on

how

to

build

it.

Early

Flight

Tests

The

Day 94

flight

test and

development

report

contains

details

of the

early

failures

and test

flights

leading

up to

successful

launches. |