Design

While the overall size and shape of Dark

Shadow will be similar to The Shadow, there

are a few differences for improved

performance.

- The pressure chamber will be

reinforced with carbon fiber.

- The payload section will be smaller

to reduce weight.

- The rocket will have a tail cone for

better aerodynamics.

- The fins will be thinner

- The pressure chamber bulkheads will

be integrated into the pressure chamber

design.

- The nozzle will be smaller to reduce

the overall acceleration to levels

similar to The Shadow.

- A new launcher will be built based

on the Polaron G2 electronic launcher.

- The rocket will use a tower launcher

and will not have rail buttons.

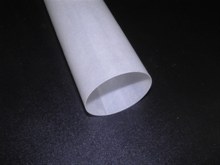

12 June 2014 - Made

a sample tube with 3 wraps of 85 gsm e-glass cloth.

This will form the inner liner for the test rocket

body.

The tube measures 525mm long

and weighs 50 grams.

31 July 2014 -

Made the tail cone plug and forward closure plugs

from wood then spray painted them with

putty, We also trimmed the ends of the tube.

Machining tailcone plug |

Machining forward closure plug |

Plugs spray painted with putty. |

|

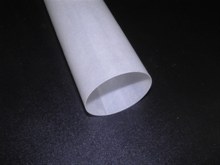

Tube as it came off the mandrel |

Ratty end |

Trimmed end |

|

1 August 2014 -

We cut

threads into plug to enable it to be mounted

during fiberglassing process. we also sanded back

the

putty for a smooth finish and then applied first coat of 2-pac clear

varnish Estapol 7008.

Applying 2-pac to the plugs |

|

|

|

2 August 2014 -

Sanded the first coat with 600 grit paper

and applied second coat of 2-pac to both.

4 August 2014 -

Sanded the plug with 1000 grit paper, put on

3 balloons and using only a little bit of

talcum powder as lubricant between layers,

cut out 13 pieces of 85 gsm glass and

applied

them around the plug, this used 1 pump of epoxy.

For a smoother finish, we added a 2 cm strip

around the base of the plug that will

overlap inside the tube.

First forward closure |

|

|

|

5 August 2014 - Pulled the

forward closure off

with difficulty. The talcum powder doesn't

work very well as lubricant on the balloons.

The forward closure is just a little too big to fit

inside the tube.

12 August 2014 - Made up

a new

forward closure with

10 gores of 85 gsm cloth and a 2cm base

strip. We also made a new nosecone with 10 x

200gsm gores bias cut and 3 veil 85 gsm

gores for a better finish. Used 3 layers of

balloons again with silicone grease between

the balloon layers.

13 August 2014 - Took the

forward closure off the

plug. With the grease it goes off a lot

easier. The outer most balloon was not

covered in anything and as a result the

balloon had glued itself well to the inside

of the forward closure. There was no way to remove

it. Hot water, and even a steel wire brush

in the dremmel could not easily remove it.

The good news though is that the 10 gores

and one strip were the correct size to fit

snugly into the tube.

The nosecone also pulled away easily from

the plug, and this time the outer most

balloon had an very thin coat of the silicon

grease. This made it possible to remove the

balloon from inside the nosecone fairly

easily. We will try using silicone mold release on

the balloon on the next attempt.

16 August 2014 - The nosecone felt a

little heavy for what it needed to be. We

can use this nosecone for other projects, So

we made up a new nosecone using only 6 x

200gsm gores + 3 x 85gsm veil gores. This

time we gave the outer most balloon a thin

coat of the silicon grease. We had also put

only two balloons on the plug.

17 August 2014 - Pulled the nosecone off

the plug very easily. So easily in fact that

the outer most balloon stayed in place. We

set up the nosecone next to a heater to get

it to fully cure

19 August 2014 - We trimmed and sanded

the nosecone down with sandpaper under a

running tap. This part of the nosecone now

weighs 19 grams. The final nosecone we are

aiming at being closer to 30 grams. The

current Shadow II nosecone weighs 67grams.

The entire Shadow II payload section

including all electronics, cameras and

parachute weighs in at 380g. We are aiming

at around half of that for Dark Shadow.

Running simulations on Shadow II, That much

weight saving would result in another 140

feet altitude.

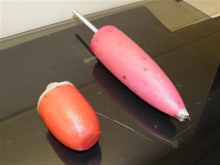

23 August 2014 - Today we machined up the

first forward closure from a chunk of PVC for the

forward closure.

We need to bring the end of the rocket to

a close and attach a mounting point for the

parachute. This part of the rocket may

experience a significant load during

parachute deploy. Probably close to an hour

later of deciding on the shape and machining

it from a lump of PVC. We ended up with a

cap that was a bit bigger than what would be

ideal. The shape is difficult to create by

hand. It also weighed in at 25g which was

pretty heavy.

So we started talking about

alternatives, and we finally did a quick

prototype of using the top of a PET bottle

and heat shrunk over the tail cone plug. It

looked like it was going to work if some of

it was filled in with epoxy. With the carbon fiber over the top of it, it should be

strong enough to hold in place. At this time

we turned to see if we could also use the

same concept for the nozzle end. We heated

up the top of a PVC pipe and widened it so

that it would not pass through the neck. The

idea was that we would fit the final nozzle

into that.

We are looking at using the same

technique for both the top as well as the

nozzle. The first shrinking worked fairly

well although it was a little uneven. So we

tried again with another top but this time

with a larger section of the bottle.

We also tried making one for forward

closure. For this we found that the bottles

with the conical top work better because

they have a wider top. We used the heat gun

to shrink it but as it was shrinking it

started moving up. So that was a fail.

Finally we put the plug with the

fiberglass forward closure over it into the lathe,

and then using the tail stock held the top

of the bottle against the plug to prevent it

from moving up and also used the PVC pipe in

the throat to stop it from collapsing. Set

on about 200rpm, we used the heat gun to

evenly shrink the bottle over the fiberglass.

This worked really well and gave us a well

aligned bottle. The uneven bottom edge was

just trimmed off. The cap now only weighs 7

grams. We trimmed the big flange on the

bottle down with a dremmel tool too, and the

thread and other flanges on the neck will be

used to hold the carbon fiber sleeve over

the top.

24 August 2014 - We fiberglassed another

forward closure, as well as the first tail cone

today. They both used 10 gores of the 85gsm

cloth with 1 wrap of 2cm wide cloth for the

gluing edge. We again used a couple of

balloons on the plug and a thin coat of

silicone grease on top.

We also bought a roller cutter for

cutting the fiberglass, and it works like a

charm. I don't know how we ever managed

without it all these years.

We mixed the remainder of the epoxy with

microballoons to make it easier to sand, and

we covered the nosecone with the mixture to

fill in any holes. We then used a scraper to

remove as much of it as possible to help

reduce the sanding time.

25 August 2014 - We pulled the tail cone

and end forward closure off the molds and they again

came off easily. The forward closure was a perfect

fit into the tube, but the tail cone was a

little on the small side. We will make the

tail cone again, but this time we'll use 12

gores, 3 balloons and perhaps 1.5 wraps of

the 2cm wide strip, for a better fit.

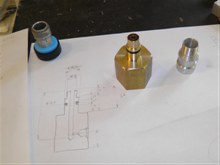

30 August 2014 - We made a nozzle insert

today from a piece of PVC pipe and enlarged

one end of it to fit inside a bottle neck.

We also cut a thread in it so that we could

screw in nozzles. Having the ability to

replace the nozzle is important in case it

gets damaged on landing. If the nozzle was

there permanently we would have to replace

the whole rocket. This time the nozzle will

not be protected like it was with the Shadow

and Shadow II, so there is higher likelihood

of damage.

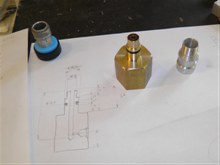

We also machined up the nozzle from

alumnium. An o-ring will be sandwiched

between the insert and the nozzle. The final

nozzle diameter is 15.5mm which is about 65%

of Shadow's cross sectional area. The reason

for the reduced nozzle is that with the

expected higher pressures we want to keep

the overall acceleration down. At 600psi

with the smaller nozzle the rocket will have

acceleration similar to that of Shadow -

around 55G+. The launcher will use a

standard 15mm aluminium launch tube.

We then heat shrank a bottle neck to fit

over the tail cone. We again did this on the

lathe to get it aligned.

Next we machined up a hose adaptor so

that we could extend our hose another 5m

just to add some more distance between us

and the rocket. We now have about 17m of

hose. If the hose has a 6mm diameter

internal hole, then the total hose volume

will be in the order of 480mL. We need to

take this into account when calculating how

much air to bring to the launch site.

Lastly for the day we pressure tested the

hose to 600psi (~40bar). The intended

pressure for the rocket. The hose was

terminated with a quick release connector

connected to the head of regulator. We made

sure we sat behind a screen door in case the

hose intended to let go.

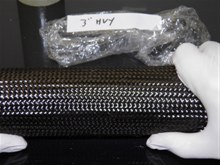

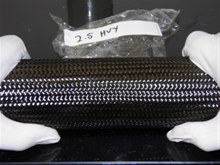

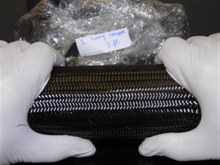

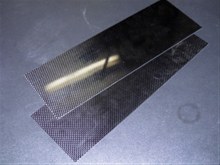

2 September 2014 - We received the carbon fiber

sleeve samples from Soller Composites. The

sleeves look very good. The heavy grade

looks like it will do the job. It will be

interesting to see how many layers are

needed to achieve the desired strength. I

would expect that even one may be enough,

but probably two. We tried threading the

tube inside the sleeves, and it looks like

the 2, 2.5 and 3 inch sleeves could be used.

We'll need to see what angle the fibers make

when the sleeve is pulled tight over the

tube. The 1.5" sleeve is too small to fit on

the tube.

3 September 2014 - Did research today on carbon

sleeves and how they are applied. It looks

like we will need to get the slow hardener

to give us enough time to work on the sleeve

for the entire rocket. This is going to be a

big job, and may need an additional person

as well. The ideal winding angle is 55

degrees from the axial axis. We will need to

put the sleeves on and measure the fiber

angles the different sized sleeves give when

pulled tight.

4

September 2014 - Stretched the

sleeves over the tube today and took

pictures of the filament orientation. We

measured the 2", 2.5" and 3" heavy sleeves

and found them to have fibers at 60, 43 and

34 degrees respectively. This means that we

will most likely go with the 2" sleeve as it

is the closest to 55 degrees. If we find

that we need a second layer, we'll then

apply the 2.5" sleeve over the top of that.

5

September 2014 -

Plugged launch tube. One of the main things that we are

concerned about is the amount of heat

generated during pressurisation of the

rocket. The glass transition temperature if

fairly low of the West systems epoxy so we

need to keep under that to reduce the

chances of failure on the pad. This means a

fairly slow fill. Unfortunately the thermal

conductivity of fiberglass is very low and

carbon fiber isn't much better, so cooling

the outside of the rocket won't help much

with reducing the temperature on the inner

wall, We need to cool it from the inside.

Simply bubbling the air through the water

won't cool it very much at all as we've seen

in our other experiments. So we are going to

try using foam to cool the air and rocket

due to the large surface area, it should

transfer the heat into the water. The other

advantage is that foam may be able to

provide additional performance boost. The

problem is how to generate the foam inside

the rocket when there is a launch tube? So we are going to plug the

launch tube just above the nozzle and below

that we will make a series of small holes

that will bubble up through the water to

make foam. When the rocket launches and gets

above the fill holes no air will come down

the launch tube. If you didn't have the

plug, the air would escape through the top

of the launch tube and out the fill holes.

The fill holes also allow you to

depressurise the rocket if needed.

6

September 2014 - Machined up a small

aluminium cylinder that can be used inside

PVC pipe for better grip in the lathe. We

also machined up an expander for PVC pipe

out of brass bar stock. At first the

expansion angle was too great and was

causing the PVC pipe to buckle. So we

reduced the angle, We also tried preheating

the expander before putting on the PVC pipe

and also heating it up. This time the PVC

pipe expanded nicely.

Procedure for making PVC

nozzle insert:

-

Cut 60mm of PVC pipe

-

Insert support cylinder

and trim one end on lathe.

-

Counter sink the end of

the tube by hand.

-

Make a hole 17.6mm

diameter - some PVC is already this

size.

-

Cut thread using a tap

on the lathe. Supporting the end using

the tail stock and using an adjustable

spanner so it keeps it from turning. Go

about 15mm deep.

-

Cut off 33mm from the

threaded end with a cutting bit in the

lathe.

-

Hand counter sink other

end by hand on the lathe.

-

Insert nozzle into PVC

thread.

-

Put expander in the

lathe and preheat with a heat gun for 40

seconds (Black II, Red III) and rotate

on low RPM

-

Put PVC on expander and

continue to rotate and heat

-

When end of PVC changes

shape slightly, remove heat, stop the

lathe and push PVC onto expander up to

the stop.

-

Blow on it to cool it

down.

8

September 2014

- Made a new tail cone today using 12

gores of the 85gsm cloth and wrapped the

base 2 times. The end of the tail cone gave

me a little trouble as it wouldn't quite

adhere to the plug. So I made a small paper cone and sat it onto the tail cone to keep

all the fibers together. Although the paper

will stick to the tail cone it will be easy

to sand off.

We weighed a number of the

different components today.

9 September 2014 - We

pulled the tail cone off the plug, and the

paper cone keeping the fibers down looked

like it worked well. However, when we tried

it inside the tube, the tail cone was still

just a little too small. It maybe needed

another 1 or 2 wraps of fiberglass to make

it fit right. This is undesirable because

there would be too much of a step between

the inside and outside helping to

concentrate stress. The diameter of the

forward closure plug is 59.1mm while this one is

58.3mm. Not wanting to make up another plug,

my wife suggested, why not just wrap the

plug in a couple of layers of fiberglass to

widen it. And so we did. We added two wraps

of a wider strip of the glass, and 2 layers

of a narrower strip so 4 layers all up. This

should bring it up to about 59.2mm or so

which can then be sanded back. This will

allow us to then go back to using the 10

gores and single wrap for the tail cone.

|

|

|

|

|

12 September

2014 - We

epoxied a small plastic ball into the

nosecone of the rocket as this had the right

diameter. We sanded back the tail cone to

smooth out the fiberglass. This doesn't need

to be polished, as we have a balloon that

sits over it.

13 September

2014 - We

made a new tail cone using the 10 gores and

single wrap around the base. Only two

balloons were used for this plug. This time

we again used the paper cone on top to keep

the fibers together.

14 September

2014 - We

removed the tail cone from the plug and it

separated fairly easily. Test fitting it

inside the tube gave very good results and

should be good to use for the test chamber.

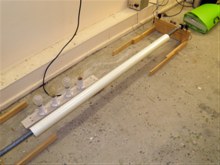

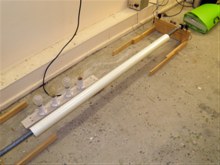

Day 150 Plugged launch tube

experiment. See Day 150

update. We wanted to see if we could get foam generated inside a

rocket during filling while using a full bore nozzle and full

length launch tube. So we adapted a normal Clark Cable-tie

launcher and drilled 6 holes near the nozzle inside the rocket.

This would allow air to bubble up through the water and form

foam. Even back in 2007 Damo was using holes in the bottom of

his launch tube, but the launch tube was not plugged. There are two problems with this approach. The air wants

to flow up the launch tube instead of through the holes, and

once launched the air can escape out of the holes through the

launch tube. So we simply plugged the launch tube above the

little holes. This way as the rocket moves up the launch tube,

the air can't escape from the rocket.

One disadvantage is that you can't use ARB boosters with the

plugged tube.

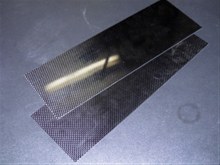

3 December 2014 - We

received 2 carbon fiber plates today from

hobby king. These are 1.5x300x100mm and

should be sufficient to make up to four

fins. (3 fins + 1 spare)

|

|

|

|

10 December 2014 -

We prepared the shrunken plastic bottle for

gluing by cutting little notches around the

edge. The idea here is to help spread the

forces along the interface between the

plastic bottle and the fiberglass shell. We

also drilled a number of small 1.5mm holes

into the plastic bottle to help get it to

"key" with the epoxy. We removed most of the

bottle flange with a sander in the dremmel

which will allow the carbon fiber to conform

better to the shape. We left a little bit as

it will help grip the CF sleeve better. We

also sanded the entire inside and outside of

the bottle with 120grit sandpaper for better

adhesion. We then glued the bottle top to

the fiberglass shell with 24hr Araldite. We

filled the top of the bottle with more epoxy

this time mixed with microballoons to help

provide support for the top of the pressure

chamber. We then added a weight to the top

to help compress the join.

We also glued the PVC nozzle insert into

the tail shrunken bottle neck. Again we

mostly removed the bottle flange for better

sleeve conformity, and cut a series of notches

along the edge. We also used the 24Hr

araldite for this.

11 December 2014 -

We glued the bottle neck with PVC insert to

the fiberglass tailcone and again added

weight on top to help seat it

properly.

17 December 2014 - Glued tail cone to body.

18 December 2014 -

We sanded the joins, and filled the gaps

with epoxy and microballoons. We are trying

to reduce the chance of little air pockets

developing after we put the carbon fiber

sleeve on.

Length of sleeve compared to

pressure chamber |

|

|

|

19 December 2014

- We wrapped the fiberglass pressure

chamber with

2" heavy CF sleeve and, used 3 pumps of

the epoxy which was not enough. We used

peel ply in a spiral fashion around the CF

to give it a better finish. We held the

sleeve down

with wire while pulling it tight and used fiberglass strands to help

hold CF sleeve in place. Next time we will use

wire on everything, and then apply the fiberglass after the CF has hardened.

We used the tap to hold the nozzle

end of rocket and a piece of PVC pipe to

hold the other end while laying it up. We also made the nozzle

seat for the launcher.

Preparing to pull the sleeve on |

Sleeve in place with peel ply

applied |

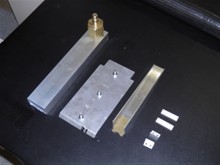

Machining nozzle seat |

Nozzle seat completed. |

20 December 2014

- We trimmed the excess CF from test

pressure chamber. This was just done with a

hacksaw. We also

cut out the forward closure gores x 20. But

when we tried making up another forward

closure with them, we failed miserably. This

fiberglass is just too stiff to

conform nicely to the shape like the

previous glass. We'll have to get more of

the original 85gsm glass. We also filled the top of neck with extra

epoxy. We wrapped extra fiberglass threads

around end of the sleeve to replace wire that

was there holding things in place

temporarily.

Test pressure chamber with

peel ply removed. |

Excess CF at one end

|

And at the other.

|

Getting ready to fiberglass

forward closure. |

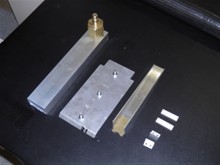

23 December 2014 -

We made a temporary nozzle

retainer for doing pressure tests. This

basically consists of two plates with a pair

of bolts holding the nozzle down against the

nozzle seat. We also tapped 2

mounting holes in the bottom of the nozzle

seat for later mounting on the launcher.

24 December 2014 -

Made up more laminated

balsa sandwiches These have a 200gsm cloth

overlayed with bias cut 84gsm cloth over the

outside. We use any left over epoxy for

these sandwiches. We also made the payload bay body tube

with 6 wraps

84 gsm e-glass. Length of glass 1150mm.

Finally we added

glass filament reinforcement to test

chamber ends to strengthen them.

25 December 2014 - We worked on the deployment

mechanism prototype today. We wanted to make

some improvements over Shadow's deployment

mechanism. The one biggest drawback with the

previous design was that it was friction

dependant. The nosecone had to be tight

enough to not separate on burn out, but not

too tight so the piston could push it out.

The friction properties varied based on

temperature and humidity. The other problem

was the shock cord got in the way of the

piston and so had to be attached to the

payload bay wall. There was always a danger that

the payload bay could be ripped off the

pressure chamber. The piston mechanism was

also quite long and heavy. The new system

gets rid of the piston, allows the shock

cord to be attached to the main pressure

chamber, is positively retained (not

friction dependant) and is shorter and

lighter. We'll do a detailed writeup of the

entire mechanism once the final design is

complete.

We also pressure tested the test

chamber to 100psi but 2 leaks in the body

were found. These must have come from tiny

holes in the rocket body. So in an attempt

to fix this we applied another coat of

epoxy to the outside.

We made a nosecone bulkhead and glued it into

a coupler we had made previously for the

Shadow project. We also added the swinging

grapple arms to the deployment mechanism

prototype.

|

|

|

Getting ready for low pressure

leak test

|

Pressurising to 100psi - couple

of small leaks

in the body itself |

Painting the surface with more

epoxy

to stop the leaks. |

Parachute grapple arms |

Grapple arms open |

Grapple arms closed |

26

December 2014

- After the epoxy had cured we pressure tested the

test chamber to 100psi and to great relief

it was without leaks. We also tested

prototype deployment mechanism to see if the

arms would let go of the parachute.

Originally we were going to use a spring

mechanism to swing the arms open, but in

testing it was found that this is

unnecessary and the arms let go of the

parachute freely.

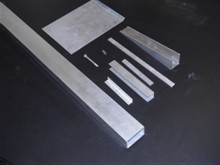

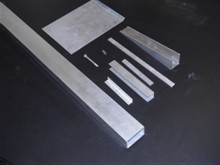

27 December 2014 -

We bought aluminium 30x50x2mm box section

today along with another PVC pipe.

The box section will become the basis of the

launcher and the PVC pipe will be machined

down to form the long tube coupler mandrel.

28 December 2014 -

Today we tested the test pressure chamber to

650psi (45 bar) and it still held. :) We

couldn't go higher because we only tested

the hoses to 600psi previously. There were

no visible stress markings on the pressure

chamber. So we are not sure how close to the

limit that is. We also rolled the first of

the long tubes that will make up the basis

of the rocket. The tube is made of almost 3

wraps of the 84gsm glass cloth The cloth is

1150mm long. We used 3 pumps of epoxy. We

also used a cheap roller that ended up

losing bits of it. We also started gathering

up all the components for the launcher.

|

|

Putting the test chamber in a

scuba tank. |

We put the connection against

the house

in case things went flying |

Ready for the test |

Rolling new full length tube |

Making up fiberglass-balsa

sandwich

for bulk heads |

|

|

29 December 2014

- We ordered a pair of

Aerocon 36" parachutes today. With the

higher performance of this rocket we wanted

to have a more sturdy parachute for

potentially higher speed deploys. We also

ordered 30 feet of the 2" heavy carbon

sleeve from

Soller Composites.

We also tested a prototype of the release

mechanism. After spending several days of

trying to figure out a latch, lever and

servo mechanism to release the grapple arms,

we decided to just use a loop of wire hooked

over the servo motor horn. By hooking the

wire over the axel of the horn it can hold

quite a bit of force. When the servo motor

turns, it just slips the wire off releasing

the grapple arms. We can also easily adjust

the length of this loop.

We made some more progress on the

launcher making a few of the smaller

components and the lever arm.

We pulled the long tube off the

mandrel ,but are less than happy with the

result. Because of the size of cloth we

weren't able to quite get 3 complete

wraps (about 1 cm short) and the frilly

edges left a few bubble pockets along the

length.. While this would have been fine for

a shorter tube, we need a bit more rigidity

when we pull the sleeve over it. The cheap

roller also left quite a few little bumps on

the tube, presumably bits of the foam. So we

will make up another tube with the frills

cut off, and then add another single wrap as

a second piece. This should also help reduce

the chance of porosity in the tube.

Parachute inside grapple arms |

Hold down wire |

Components for launcher |

Less than satisfactory first

tube |

30 December 2014

- We rolled a second full length tube

today with 4 wraps of the 85gsm cloth. This

time we used the better quality foam roller

and the results were much better. We also

continued to work on the launcher. The main

base components are now mostly complete. We

are using a brass insert in the lever arm to

add extra strength to the nozzle contacting

surface.

Rolling full length tube |

Starting launcher construction |

|

|

31 December 2014

- Rolled second full length tube the

same way as the first. Made up the base of

launcher and attached it to the bottom of

the box section.

Second full length tube |

Old and new tubes |

|

|

Continue to Part 2...

Dark Shadow Parachute Deployment Mechansim |