Overview

If you are considering using a scuba tank to pressurise your water

rockets then this article covers a number of issues you should consider

first before making the investment. Although scuba tanks are likely to

have the highest start-up costs when compared to hand pumps or small

compressors, once set up, the cost per launch is very small and usually in

the order of

a few cents.

Scuba tanks are also known as scuba cylinders or

diving cylinders.

|

|

|

Advantages

- No effort is needed when filling rockets like you have with

hand or foot pumps.

- No power supplies or generators required as you may need

for

compressors.

- You can fill rockets quickly which allows you to launch more rockets

during a launch event.

- You can pressurise large rockets easily.

- You can fill rockets to high pressures easily.

|

Disadvantages

- Expensive set up if you need to buy all the components.

- There is a need for refilling the tank with potential restrictions

on who and where they can be filled.

- They are heavy to carry around.

- Special handling precautions are needed for compressed

gasses.

|

CAUTION

Before we jump in, it's important to first consider the safety

aspects of compressed gasses. Pressurised tanks can be hazardous if not handled with respect. You

should always follow the correct safety practices when handling scuba

tanks, as you would with any other pressurised tank.

- Do not overfill the tank past it's ratings.

- Keep moisture out of the tank. Internal corrosion could become an issue.

- Don't leave your scuba tank in a hot car. Pressure will build up

inside the tank when it gets hot.

- Have your tank regularly inspected and hydrostatically tested.

There are standards on how often this should be done.

- Do not drop the tank onto the valve. In fact, don't drop it at

all! You don't want to know what happens when a tank valve is

broken.

- Transport your tank horizontally and secured it to prevent

it

from rolling around.

- Store your tank vertically.

Other Important Safety Considerations

- If you adjust the intermediate pressure on the 1st stage

regulator, Label the stage "Not for breathing" to make sure

someone doesn't come along later and try to dive with

it only to discover they aren't getting enough air 100 feet below the

surface..

- Use only high pressure (HP) hoses for connecting components to the HP port of

the 1st stage regulator. These need to be able to handle at least

3000psi.

- Avoid making your own adaptors for any HP connectors, Only use

commercial components rated for the pressure.

- Fill your rockets slowly. Filling them quickly can cause

excessive internal heating weakening the plastic and causing them to

fail prematurely.

What you need to set up a Scuba tank air supply for your water rockets

Before looking at how we can connect everything together let's have a

look at some of the components that you may need for the air supply.

You may want to jump ahead and see some of the

configuration options so

that things are clearer where the different components fit in the

whole scheme of things. Click on the links below to find out more about each

component,

Scuba Tanks

Tank Sizes

Scuba tanks come in quite a few different sizes and are usually made

from steel

or aluminium. Larger tanks store more air

but make transportation a little more difficult if you have

to carry them to the launch site. The following table shows a list of

some common tank sizes and their operational pressures:

|

|

| Cylinder |

Air |

Weight |

| Material |

Volume |

Pressure |

Volume |

Full |

| |

(litre) |

(bar) |

(litre) |

(kg) |

| Steel |

12 |

200 |

2400 |

19.0 |

| 15 |

200 |

3000 |

23.8 |

| 16 (XS 130) |

230 |

3680 |

23.9 |

| 8 |

300 |

2400 |

16.0 |

| 10 |

300 |

3000 |

20.8 |

| Aluminium |

9 (AL 63) |

203 |

1826 |

13.5 |

| 11 (AL 80) |

203 |

2247 |

17.2 |

| 13 (AL100) |

203 |

2584 |

20.3 |

|

Here is some more info on tank sizes:

http://www.huronscuba.com/equipment/scubaCylinderSpecification.html

Tank valves

There are two main types of tank valve used on scuba tanks. The DIN

valve has an internal thread for connecting the regulator, while the

K-valve uses a yoke. There are also two kinds of DIN fittings: 200 DIN

fitting which is rated for 200 bar and 300 DIN which is rated for 300

bar. You can connect any equipment with 300 DIN fittings to the

200

DIN valve, but not the other way round.

It's

not important what kind of valve the tank has for our purposes,

but it will affect what type of regulator you should buy for your tank.

There are adaptors available to connect one to the other but these just

add extra cost. DIN fittings are popular in Europe while the Yoke type

are more common in the US. There really isn't a price difference between

the two.

K-valve or Yoke |

DIN Valve |

Here are two examples of 1st stage regulators, one with a Yoke

fitting and one with a DIN fitting.

Yoke fitting (left) and DIN fitting (right)

Regulators

Standard scuba equipment uses two pressure regulators. The

1st stage regulator goes on the tank and converts the tank

pressure down to an intermediate pressure (IP) of around 140-150 psi (10

bar). The

2nd stage (demand valve) connects to the 1st stage via a hose and goes in your

mouth. The 2nd stage converts the intermediate pressure to a pressure

you can breathe which varies with depth. You generally do not need the

2nd stage regulator for water rockets.

Terminology Note: For clarity in this article we will often refer to the

Intermediate Pressure (IP) as Low Pressure (LP).

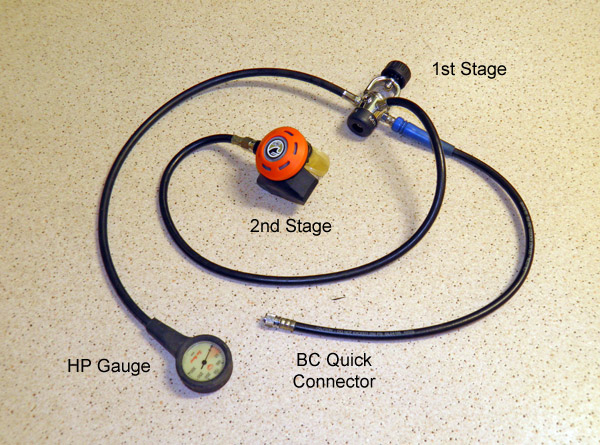

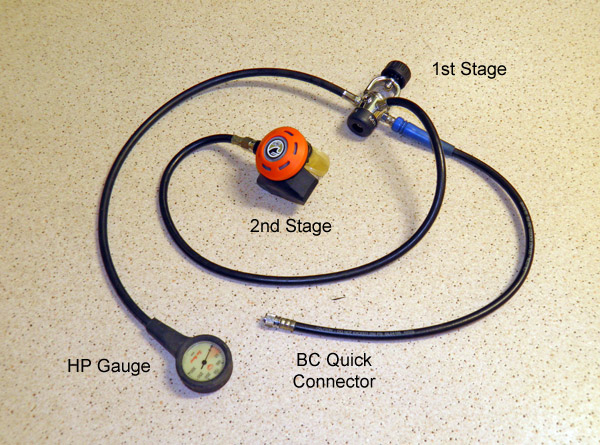

|

Typical scuba regulator setup with 1st and

2nd stages, a high pressure gauge and a BC connector. |

There are two main types of 1st stage regulators - one uses a piston

and the other uses a diaphragm. Piston first stages tend

to be cheaper and easier to service while the Diaphragm first

stages are sealed, and can have their output pressure

adjusted. If you have a choice of which regulator to get, I

would recommend the diaphragm type for it's pressure adjustment

capability.

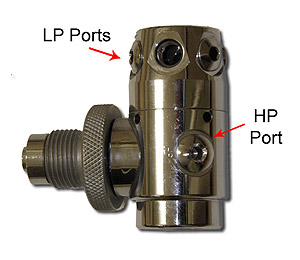

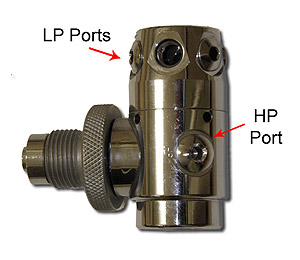

A typical 1st stage regulator will have 1-2 two HP ports and 2-5

LP ports available for you to connect various equipment to, The HP ports are

typically marked on the regulator body. Any unused ports need to be

plugged with LP or HP plugs.

|

An example of a 1st Stage

regulator

showing HP and LP ports |

Plugs seal unused

ports |

Adjusting pressure

You can adjust the pressure of a diaphragm regulator usually with an

Allen key. NOTE: for most purposes you probably will not need to do

this, but it is a way to increase the intermediate output pressure of

the 1st stage regulator. If you decide to change the set pressure, label

the regulator "not for breathing" as mentioned in the safety

considerations. The range over which you can adjust the pressure depends

on the regulator model, but in general you should be able to adjust it

from 0 to about 200psi (14 bar). The default setting is usually around

140 - 150psi (10 bar)

An Allen key can be used to adjust

pressure on a diaphragm regulator |

This regulator has a slot instead of a hex head for

adjusting pressure |

Pressure gauges

You would normally use two pressure gauges on your scuba tank water rocket

air supply. The high pressure gauge tells you how much air is left in the tank, and

the low pressure gauge tells you how much

pressure is in your rocket/launcher.

A typical HP gauge will show

pressures in the range of 0 - 4000psi ( 0 - 300bar ) while a low pressure one

will show 0 - 300psi (0 - 20 bar)

High Pressure gauge |

Low Pressure gauge |

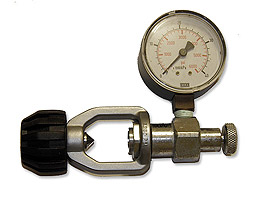

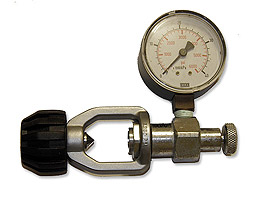

You can also buy pressure checking gauges that fit on the

scuba tank instead of the 1st stage regulator. They come with their

own yoke or DIN fitting and have a pressure release valve. Here are

a few examples:

Pressure checking gauge

with a yoke fitting |

Pressure checking gauge

with a DIN fitting |

Pressure Checking gauge

attached to a tank |

These are useful when your 1st stage regulator

doesn't have a high pressure gauge.

Pressure release valves

A pressure release valve (also know as a bleed valve) is used to depressurise a pressurised

portion of your air supply. These can take any number of forms. Here are

a few examples:

|

2nd Stage Regulator

When connected to the 1st stage, pressing

the purge button will release the pressure.

|

|

|

Bleed valve on LP gauge

Sometimes the low pressure gauge will have

an integrated pressure release valve.

|

|

|

Separate valve

You can pretty much use any valve rated to

the pressure as a release valve. Just use the correct

adaptors to connect it to a hose or air manifold. |

|

Hoses

There are two different types of hoses commonly used with scuba

equipment. A high pressure (HP) hose connects your HP gauge to the HP

port of your 1st stage regulator. Low pressure (LP)

hoses connect to the 2nd stage regulator and a buoyancy compensator

(BC) for example. For water rockets you need to be able to connect your launcher to

one of the LP hoses. There are several different ways of achieving this.

You can use a standard air hose that you may already have on your

launcher, and then use an adaptor that will allow it to connect directly

to the LP port on the 1st stage.

Alternatively you can use a standard scuba hose with a

quick connector (normally used for connecting to a BC) and then attach a

quick connector adaptor to the end of your hose. The one advantage to using the quick connector is that it

has a valve in it, and when disconnected it closes so that you can

measure the tank pressure.

|

|

|

Typical LP and HP pressure hoses |

A scuba hookah hose |

Typical scuba hoses are available in short lengths

usually around a meter with connectors at either end. Since you will

need a longer hose for your launcher you will need to connect a scuba

hose to your longer air line. Unless of course you use a number of

adaptors and connect the short hoses together. Long scuba hoses are also

available called "hookah" hoses that allow you to connect directly

to the LP port but are less common and more

expensive.

Hose Adaptors

Hose adaptors come in lots of different varieties, and

which ones you use will depend on your specific set-up. Here are just a

few

examples of the different kinds of adaptors you may find useful when

connecting to scuba gear. Use your

favourite search engine to find the adaptor you need. In some instances

you may need to use a couple of adaptors to get the desired conversion.

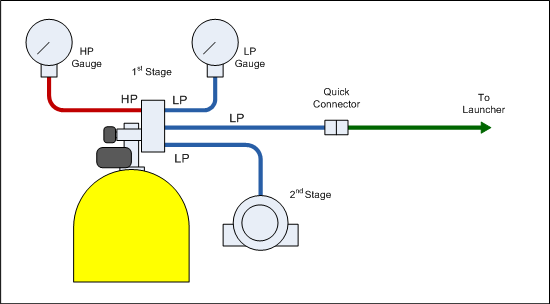

Putting it all together

When setting up your air supply you have several configuration

options to choose from depending on your preference and what equipment

you may already have. Here are some suggestions for connecting your

scuba tank to your launcher:

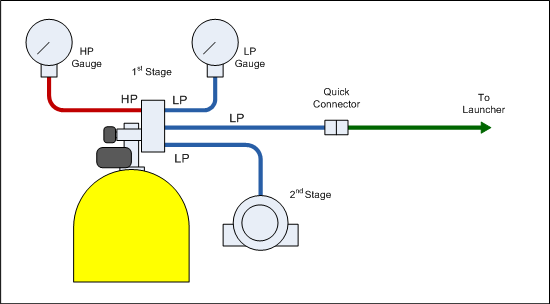

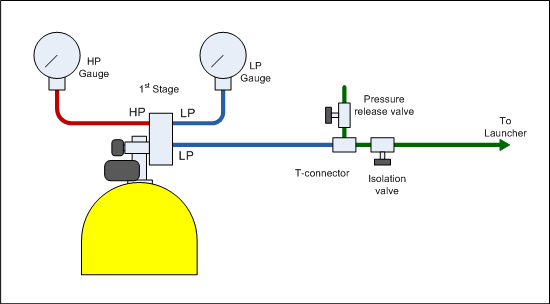

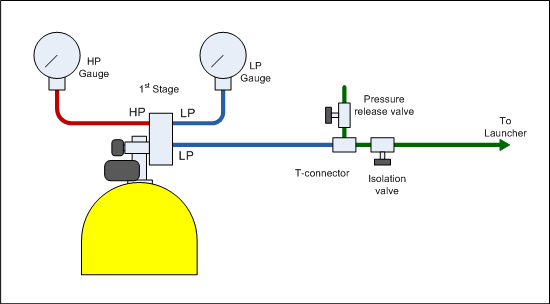

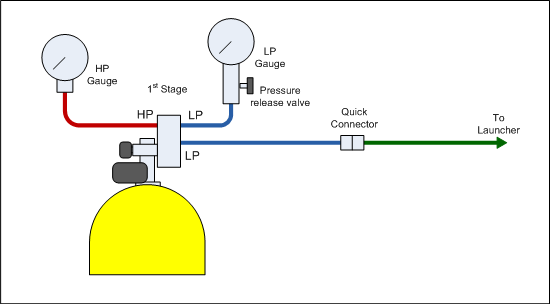

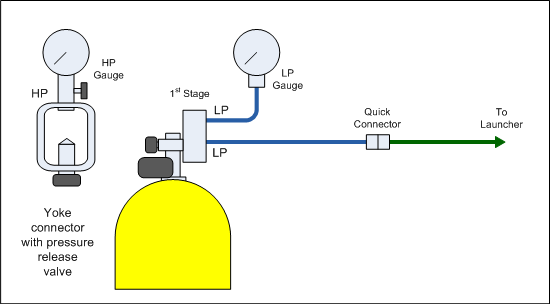

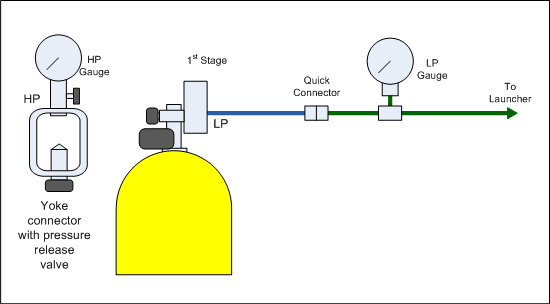

Blue represents LP scuba hoses,

Red represents HP scuba hoses, and

Green represents other air hoses

that are a part of the normal launcher.

The quick connectors referred to here are the kind used to connect

to a Buoyancy Compensator (BC). They have an internal valve that closes

when disconnected.

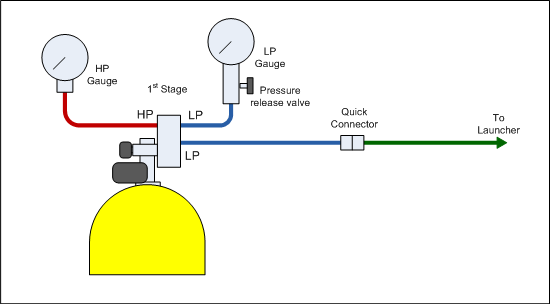

| Option A 1st stage regulator with a LP gauge,

hose with quick connector and 2nd stage connected to 3 LP

ports. A HP gauge is connected to a HP port on the 1st

stage.

To measure the HP pressure you need to disconnect the

quick connector, and then open the tank. After taking a

reading, press the purge button on the 2nd stage to release

the pressure. |

|

| Option B

1st stage regulator with a LP gauge and hose with hose

adaptor connected to 2 LP ports. A HP gauge is connected to

a HP port on the 1st stage.

The LP hose is connected to a manifold with a pressure

release valve and an isolation valve. These could be any

kind of valves and may be present on the launcher already.

To measure the HP pressure, you need to close both the

isolation valve as well as the pressure release valve and

open the tank valve. After taking a reading, close the

tank valve and then open the pressure release valve. Open

the isolation valve for normal launches again. |

|

| Option C 1st stage regulator with a

LP gauge and hose with quick connector connected to 2 LP

ports. A HP gauge is connected to a HP port on the 1st

stage. The LP gauge has an integral pressure release valve.

To measure the tank pressure you need to disconnect the

quick connector, and then open the tank. After taking a

reading, release the pressure by opening the release valve

on the LP gauge. |

|

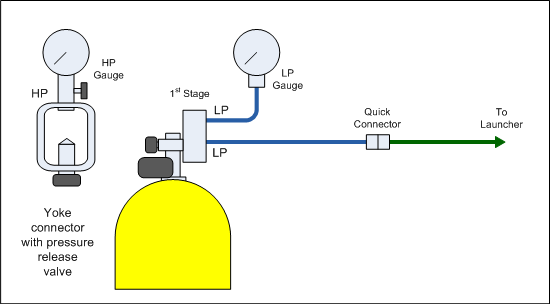

| Option D 1st stage regulator with a

LP gauge and hose with quick connector connected to 2 LP

ports.

You can use a separate pressure checking gauge to check

the tank pressure. In order to do this you must first

disconnect the 1st stage from the tank valve. |

|

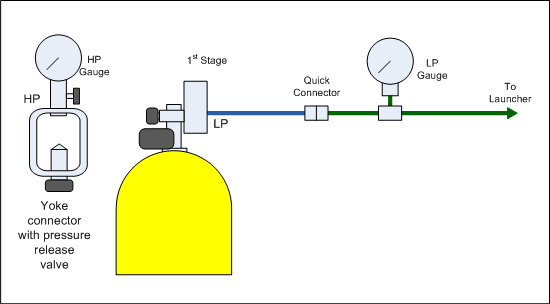

| Option E 1st stage regulator with a

hose with quick connector connected to 1 LP port.

This option is useful if your launcher is already

equipped with LP gauge.

You can use a separate pressure checking gauge to check

the tank pressure. In order to do this you must first

disconnect the 1st stage from the tank valve. |

|

NOTE: When setting up your own configuration keep the

following in mind: To take a HP reading you need to open the tank valve to allow the

full tank pressure to reach the HP gauge and at the same time you need

to isolate the rest of the system to prevent air escaping. After you

close the tank you need to use a pressure release valve to depressurise

the connection between the tank and the HP gauge. If you fail to

include a pressure release valve in your design you will have a really hard time removing the

regulator from your tank.

Pressurising your rocket

When you have everything connected, you are ready for launch. Because

the intermediate pressure set on the regulator may be too high for your

rocket, you can fill your rockets to lower pressures simply by opening

the tank valve slowly and letting the pressure build up in the launcher and

rocket. You need to be looking at your low pressure gauge. When the

pressure reaches the desired level, turn the tank valve off.

CAUTION: If you don't turn the tank valve off when the rocket reaches

the desired pressure, the pressure will continue to build until it reaches

the regulator's IP setting. This pressure may exceed the burst pressure

of your rocket and/or launcher. The same thing would happen if you fail

to turn off your compressor when it reaches the desired pressure.

With a diaphragm type 1st stage you can preset the pressure to a

lower value so that it is at the desired launch pressure. You can then

open the tank valve and air will stop flowing when the set pressure is

reached. Then you can turn the valve off again.

Before you launch your rocket, always make sure the tank valve is

turned off so you don't waste air.

How many launches do you get out of a tank?

The number of launches you can get out of a single tank depends on

several factors such as the tank volume, the capacity of rockets you are

launching and the pressure at which you launch them. The calculator

below will give you a rough idea on how many launches you can

expect.

* Note: You can use bar values instead of psi values as long as

both are in the same scale. (you cannot mix bar and psi)

How much does it cost?

The prices for the entire setup can vary greatly

depending on what components you have already and what components you

need to buy. If you are a scuba diver and already have most of the

components then the cost should be minimal. If you are starting from

scratch then it will cost a little more. I would highly suggest looking

for good bargains on e-bay or similar websites. If the equipment is in

working order there is no need for it to be brand new for our

application. Here are some prices to give a general indication of the

cost of some of the components:

| Component |

Approximate Price Range of second

hand components

(in $AUD) |

| Scuba tank |

$50-$300 |

| 1st stage regulator |

$20-$80 |

| HP gauge & hose |

$20-$70 |

| LP gauge & quick connector |

$30-$50 |

| LP hose with quick connect |

$5-$10 |

| 2nd stage |

$10-$50 |

| Hose adaptors |

$2-$10 |

The above are prices for individual components, but you

can often find good deals on e-bay that sell the 1st stage, 2nd stage,

BC inflator hose and HP gauge for $100. This would be a regulator that's

a few years old, but perfectly suitable for water rockets. All up

if starting from scratch you should be able to get a system up and

running for $200-$300 using second hand components. Although this may

seem quite a bit to start off, when you think about the cost of a good

quality pump or compressor it isn't that much more.

How much does it cost to re-fill a tank?

This will again depend on

your location but here in Australia it is about $5-$10 for a fill. Check with

your local dive shop how much they charge.

Getting tanks filled

Depending on your location it may be difficult to get your tank filled,

or you may have to drive a long way. Also depending on the specific

filling station they may require you to have a dive certification card

(c-card) before they will fill your tank. Talk to the owner about what

you want to use the tank for and that it will not be used for diving. In

some cases they may ask you to sign a waiver. You may also be able to talk to

your local paintball center and

ask them if they could recommend where to get them filled. Paintball

centers will often use scuba tanks to re-fill smaller paintball tanks.

You may also be able to find a friend who is a scuba diver and have them get the tanks filled

for you.

Tips

-

Before deciding to get a scuba tank make sure you

have a filling station nearby and is willing to fill your tanks if

you don't have a c-card.

-

When buying a second hand scuba tank make sure that

it had been inspected recently and that it's test date is still

valid. If it's past it's test date, you may need to have it tested

before a filling station will fill it for you.

References

28 / 7 / 2012

|