V1.6 Overview

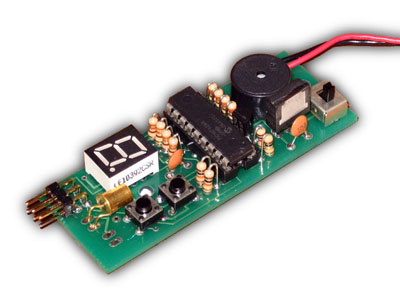

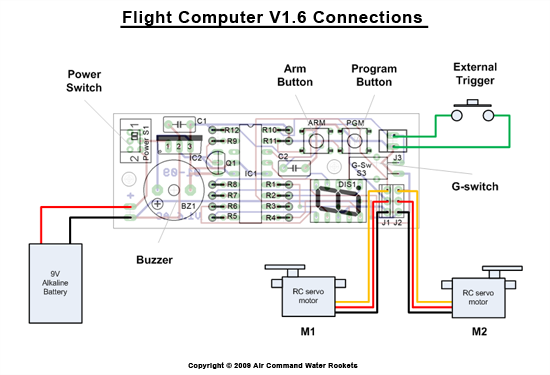

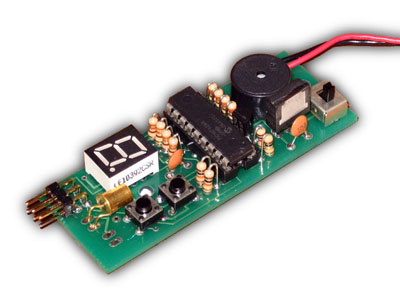

This flight computer (FC) was designed

primarily to provide timing for parachute deployment and

staging of multistage water rockets. The FC can drive one or

two standard RC servomotors that are used to release latches

on

recovery systems. The timing can be initiated

in a variety of ways such as

an acceleration switches,

pressure switches or deceleration detection. The FC

can be used on

both simple or more advanced

rockets.

Water Rocket Flight Computer V1.6

Features

The FC has the following main

features:

- Dual RC servo

motor control.

- 7segment LED

display indicating status information.

- Built in launch

detect G-switch (optional).

- External launch

detect / burnout / negative-G trigger input

- Buzzer for

indicating status and helping to locate lost rockets

- EEPROM used to

store settings while power is turned off

- 15 configurable

control parameters

These

instructions give an example of how to use the flight

computer in a parachute deployment mechanism.

Changes from V1.5

- The altimeter power connector has been removed. The

altimeter can still be powered via the second servo

connector. If both servos and altimeter are used then

the second servo can be connected to the altimeter's pass through

connector to connect the second servo motor.

- The PCB is now double sided resulting in less

weight and 25% smaller area. The PCB is also only 27mm

wide allowing it to be used inside T-8 and T-12 FTC

tubing.

- The timing parameters have been changed to represent

seconds directly rather than the more confusing

offset/multiplier technique used in V1.5. Although the

direct setting reduces the range of values possible,

they should cover the vast majority of situations as

used in the real world. The timing for both D1 and D2

phases can now be set between 0.1 and 99.9 seconds in

0.1 second increments.

- The setting of the two delay parameters in the

Normal mode have been removed and the FC now simply

requires one press of the ARM button to ARM it. This was

done to make it simpler for the rocketeer to use

in the field, and prevent accidental timing changes.

- The servo control pulse width range has been

extended to allow driving some non-standard servos their

full range.

Buy It Now

V1.6 FC

has been sold out

The Assemtech G-switch data sheet is available here:

http://docs-asia.electrocomponents.com/webdocs/0027/0900766b80027e0b.pdf

Disclaimer

In no respect shall Air Command Water Rockets incur any

liability for any damages, including, but limited to,

direct, indirect, special, or consequential damages arising

out of, resulting from, or any way connected to the use of

the item, whether or not based upon warranty, contract,

tort, or otherwise; whether or not injury was sustained by

persons or property or otherwise; and whether or not loss

was sustained from, or arose out of, the results of, the

item, or any services that may be provided by Air Command

Water Rockets.

While we try to ensure the quality of the flight computer,

we cannot guarantee a rocket's safe return to Earth since it is fitted in recovery systems beyond our

control. This product should always be considered experimental.

Operation

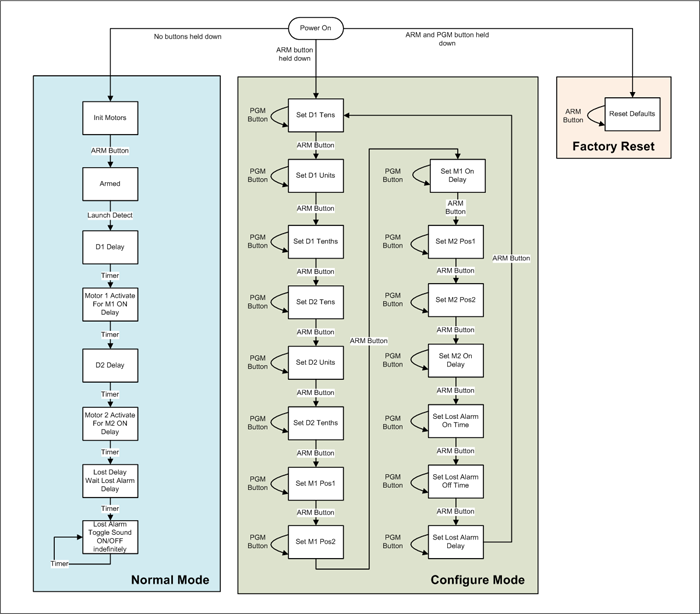

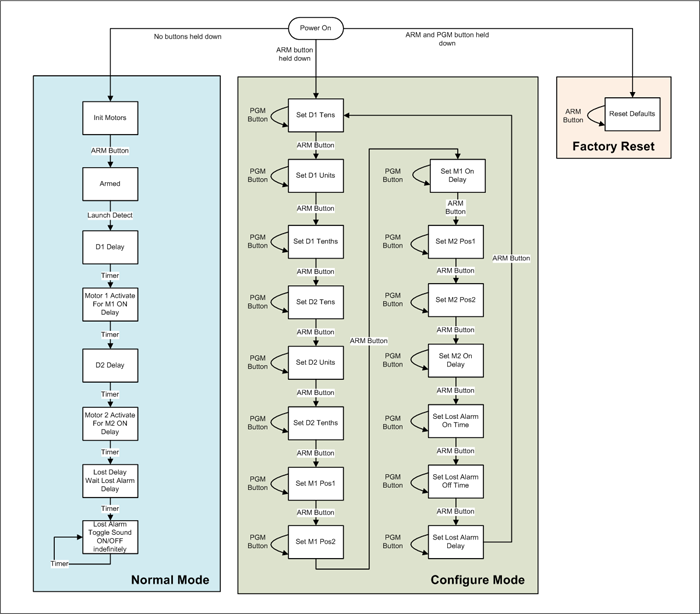

The flight computer

can be switched into one of three different modes:

- Normal

- This is the normal mode

for pre-launch and in-flight operation.

- Configure

In this mode all 15

parameters can be set to specific values.

- Factory

Reset In this mode the

configurable parameters are reset to their default

factory settings.

Figure 1 shows the flow diagram for the three modes. Each mode will

be discussed in more detail

below.

Figure 1

- Operational Mode -

Flow Diagram

Video describing the operation of the FC.

When this period expires the FC

goes to the next phase.

- M1 On Time

At the end of D1

servomotor M1 moves from position 1 to position 2. The

amount of time it spends doing that is set through the

M1 On Time parameter. The servo remains in this

position until power is turned off and turned

back on again. This is the time

that a parachute or the next stage is released.

Display shows:

At the completion of the servo

repositioning the FC enters the D2 phase.

- D2

The FC waits a second period of

time before the second servomotor is activated.

Display shows:

At the conclusion of the D2 delay the FC

switches to the next phase.

- M2 On Time

Servo M2 moves from

position 1 to position 2. The amount of time it spends

doing that is set through the M2 On Time

parameter. The servo remains in this position until

power is turned off and turned back on

again.

Display shows:

When the motor

finishes moving the FC switches to the lost delay phase.

- Lost Delay

If enabled, the FC waits for another period of time

before starting the lost rocket alarm. Typically the

rocket is found by the time the alarm sounds and power

is turned off. The period can be set from 0 minutes to

31 minutes.

Display shows:

- Lost Alarm

When the Lost Delay period expires, the alarm

starts sounding and continues indefinitely until either

power is turned off or the batteries run flat.

Display shows:

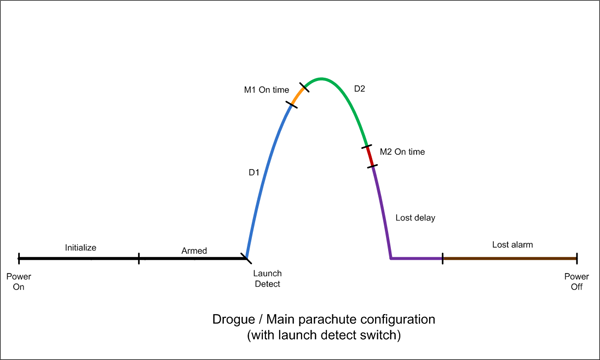

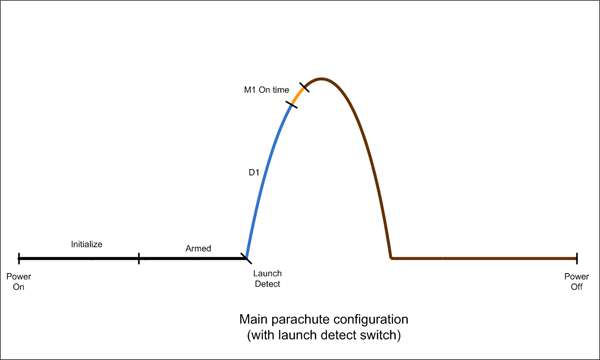

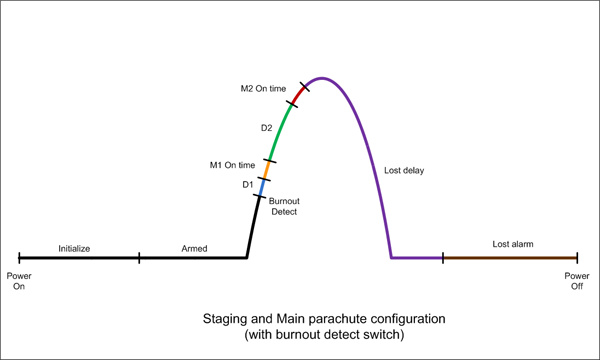

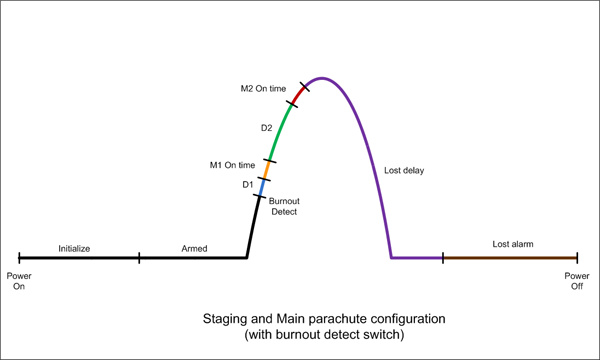

Flight Profiles

Following are

examples of a few

different flight profiles that can be configured with the FC.

Please refer to the examples section for more details on

these:

- Single stage

with launch detect or burnout detect

- Two stage

Staging and main parachute with launch detect

or burnout detect

- Dual Parachute

(Drogue/Main) with launch detect

or burnout detect

Configure Mode

In the configure mode the user can

cycle through all parameters and change their values.

All values are automatically and permanently stored in the EEPROM. Table 1

describes each of the parameters and the range of values

that can be set for each. Table 2

describes the values themselves. To avoid confusion a

parameter name on the display is designated with a .

(decimal point) and the parameter's value

does not have the decimal point.

Since the values can range from 0 to 31,

alpha-numeric

characters (0 9, and A V) are used to display all

values.

To enter configure

mode and change the parameters do the following:

- Make sure power

is OFF.

- Hold down only

the ARM button and turn the power

ON.

The S

symbol appears on the display indicating you are

in Set or configure mode

symbol appears on the display indicating you are

in Set or configure mode

- Press the ARM

button repeatedly to cycle through the parameters.

- Press the PGM

button repeatedly to cycle through the parameter values.

- When finished

changing the parameters switch the power OFF.

|

Parameterer |

Mnemonic |

Default |

Range |

Display

|

Description

|

|

D1

Tens |

D1Tens |

0 |

[0

9] |

|

Represents the number of 10's

of seconds to wait in the D1 delay. |

|

D1

Units |

D1Units |

3 |

[0 9] |

|

Represents the number of seconds to wait in the D1

delay. |

|

D1

Tenths |

D1Tenths |

5 |

[0 9] |

|

Represents the number of 0.1 seconds to wait in the

D1 delay. |

|

D2

Tens |

D2Tens |

0 |

[0 9] |

|

Represents the number of 10's

of seconds to wait in the D2 delay. |

|

D2

Units |

D2Units |

5 |

[0 9] |

|

Represents the number of seconds to wait in the D2

delay. |

|

D2

Tenths |

D2Tenths |

0 |

[0 9] |

|

Represents the number of 0.1 seconds to wait in the

D2 delay. |

|

M1 Position

1 |

M1P1 |

0 |

[0 V] |

|

Motor 1

Position 1. (prior to launch) |

|

M1 Position

2 |

M1P2 |

V |

[0 V] |

|

Motor 1

Position 2 (after delay D1) |

|

M1 On Time |

M1On |

F

(2.4 sec) |

[0 V] |

|

0.16 sec /

step |

|

M2 Position

1 |

M2P1 |

0 |

[0 V] |

|

Motor 2

Position 1 (prior to launch) |

|

M2 Position

2 |

M2P2 |

V |

[0 V] |

|

Motor 2

Position 2 (after delay D2) |

|

M2 On Time |

M2On |

F

(2.4 sec) |

[0 V] |

|

0.16 sec /

step |

|

Lost On Time |

LOn |

1 |

[0 V] |

|

How long the buzzer sounds

0.25 sec /

step |

|

Lost Off

Time |

LOff |

4 |

[0 V] |

|

How long the buzzer is silent

0.25 sec /

step |

|

Lost Delay |

LDly |

5

(5min) |

[0 V] |

|

How long before the alarm

sounds

minute /

step

|

Table 1

- Configurable Parameters

|

Value |

Index |

Displayed as

|

|

Value |

Index |

Displayed as

|

|

Value |

Index |

Displayed as

|

|

0 |

0 |

|

|

B |

11 |

|

|

M |

22 |

|

|

1 |

1 |

|

|

C |

12 |

|

|

N |

23 |

|

|

2 |

2 |

|

|

D |

13 |

|

|

O |

24 |

|

|

3 |

3 |

|

|

E |

14 |

|

|

P |

25 |

|

|

4 |

4 |

|

|

F |

15 |

|

|

Q |

26 |

|

|

5 |

5 |

|

|

G |

16 |

|

|

R |

27 |

|

|

6 |

6 |

|

|

H |

17 |

|

|

S |

28 |

|

|

7 |

7 |

|

|

I |

18 |

|

|

T |

29 |

|

|

8 |

8 |

|

|

J |

19 |

|

|

U |

30 |

|

|

9 |

9 |

|

|

K |

20 |

|

|

V |

31 |

|

|

A |

10 |

|

|

L |

21 |

|

|

|

|

|

Table 2

- Parameter Values

Functionality

Timing

The two main timing delays D1 and D2

are configured through 3 parameters each. Both D1 and D2 are configured in the

same way.

Timing Periods

Table 3

lists the minimum and maximum values that each specific

phase can be configured to.

|

Delay |

Min |

Max |

|

D1 |

0.1 sec |

99.9 seconds |

|

M1On |

0.16 sec |

5.12 seconds |

|

D2 |

0.1 sec |

99.9 seconds |

|

M2On |

0.16 sec |

5.12 seconds |

|

Lost

Delay |

0 minutes |

32 minutes |

Table 3

- Delay Ranges

Each of the servomotors has two

configurable positions Position 1 and Position 2.

Position 1 is the position prior to launch. This

would typically be the latched position of the recovery

system. Position 2 is the position of the servomotor

after the expiry of the appropriate period. The motors

remain at their Position 2 position until power is

turned off.

RC servomotors are positioned using a

specific pulse train on their control line. The FC generates

this pulse train for only a short period of time determined

by the M1 On Time or M2 On Time parameters.

This allows battery power to be conserved when the motors

are not required to move. The On Time should be

adjusted in such a way that the motor has enough time to

move from one position to the other. Sometimes this needs to

be adjusted depending on the motor used or if there is a

load on the motor and it takes longer.

The full range of movement of each

servo is divided into 32 steps. This means a servomotor that

normally has a 90 degree range of movement will be able to

be positioned with an accuracy of 2.8 degrees, while a servo

that has a 200 degree range of movement can be positioned

with an accuracy of 6.25 degrees.

The positions are made configurable to

allow the servomotors to be mounted inside the deployment

system in any orientation. Sometimes clockwise operation is

needed and sometime anti-clockwise is required.

The positions can also be adjusted

between flights in the Configure Mode if something

becomes misaligned or stretched in the deployment system and

the servomotor positions need to be updated to compensate.

HINT:

When configuring the motor positions, set the M1 or M2

On Time delays to something like "6" this will

allow you to reposition the servo motors faster as you cycle

through their positions. Don't forget to go back and set the

appropriate time delay when you are finished.

The FC can use the built in buzzer to

sound an alarm after a delay to assist the rocketeer to locate

the rocket if it is lost in tall grass or hanging in

a tree.

There are 3 configuration settings

associated with the alarm. The first is the number of

minutes it takes before the alarm is activated (Lost

Delay). This is useful for two reasons. Firstly it

allows the FC to conserve the battery since in most

instances the rocket will be found before the alarm needs to

sound. Secondly it allows the FC to remain quiet in flight

when used in combination with a video camera that is also

recording audio.

The other two parameters are used to

configure the sound duration during the alarm phase. Setting

the Lost On Time to a short beep and the Lost Off

Time to a long period allows the FC to conserve power,

but for more noisy environments the alarm can be set to

produce noise more frequently at the expense of power

consumption.

Setting the All three

parameters to

zero allows the lost alarm functionality to be switched off

altogether.

Most of the fun only happens after the

FC is triggered from the Armed phase. Triggering can be

achieved a number of different ways depending on the rocket

design. Some examples include:

- Launch

detect This is typically

achieved using a G or acceleration switch. Triggering

occurs as soon as the rocket leaves the launch pad.

Another variation to this is a set of contacts that are

closed and an insulator is removed from between them

during launch. The insulator is usually attached so it

stays with the launcher.

- Burnout

detect - This technique

uses a pressure switch to detect when the pressure

inside the rocket has reached atmospheric pressure, or

some preset value. This is useful for staging rockets.

This allows the rocket to deploy the second stage at the

correct time regardless of how much pressure or water

was used in the booster.

- Negative G

detect This is another

technique used to detect when the rocket has stopped

producing thrust and the rocket starts to slow down. An

inverted mercury switch can be used here where the

mercury floats upwards to make contact as drag continues

to slow the rocket down after burnout. Negative Gs

happen shortly after burnout.

Well leave it up to the rocket

builder to come up with their own way to trigger the FC. The

FC can have a G-switch fitted directly to the PCB, but the

FC also provides a connector for external triggers inputs.

Following are a number of examples

demonstrating how to configure the FC for various scenarios.

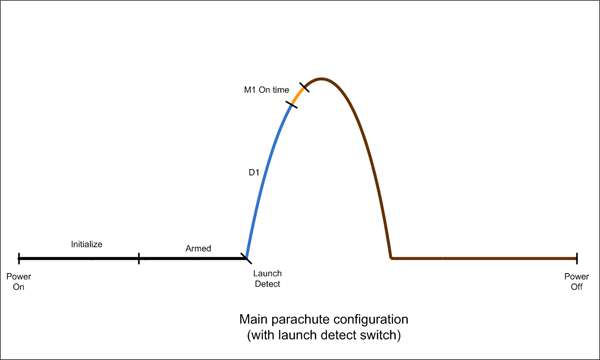

You want to use a single parachute on

a simple rocket. You want the parachute to deploy at 3.5 seconds.You also dont want

to use the lost alarm functionality. You will also be using

the built in G-switch.

Figure 3 - Simple rocket with single

parachute scenario

This is how you would configure the

computer:

Enter the Configure mode by holding the ARM button down

while turning the power ON. Use the ARM button to advance

through the parameters, and the PGM button to advance

through the values.

Motor M1 is set for full range

movement by setting 6. to "0" and 7. to

"V".

If the servo was to move in the other direction the two

values would be reversed. The servomotor will be on for 2.4

seconds. This is set by parameter 8. (value = 2.4 /

0.16 = 15 = F)

We set the C. D. and E. parameters to 0

to turn off the lost alarm.

|

|

D1 |

D2 |

M1 |

|

D1Tens |

D1Units |

D1Tenths |

D2Tens |

D2Units |

D2Tenths |

M1P1 |

M1P2 |

M1On |

Param

|

|

|

|

|

|

|

|

|

|

|

Value |

00 sec |

|

0.5 sec |

|

|

|

0 |

32 |

2.4sec |

|

|

|

|

M2 |

Lost |

|

|

M2P1 |

M2P2 |

M2On |

LOn |

LOff |

LDly |

|

|

Param |

|

|

|

|

|

|

|

Value |

|

|

|

|

|

|

When finished setting the parameters,

turn the power OFF.

Now if the rocket

will fly with the same setup on every launch, all you have

to do for each launch is turn on the FC and press the ARM

button and the rocket is ready to go. This makes it

very simple to use once configured.

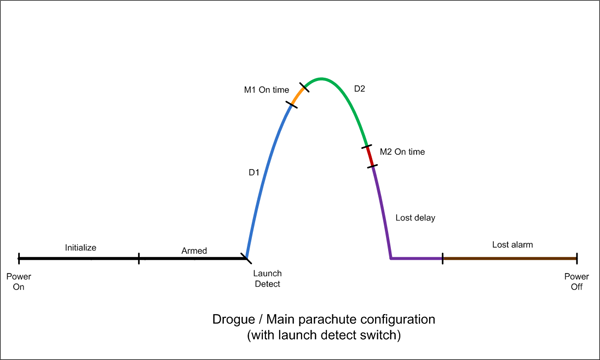

Say you have a more advance rocket

that will deploy a drogue parachute at apogee and then

the main parachute some time later when it has had a chance

to descend some way. This technique is often employed to

prevent large parachutes from being opened at high speeds as

well as to stop the rocket drifting too far in windy

conditions.

You also want to use the lost alarm

functionality as you are flying in wooded terrain.

A simulation of the rocket predicts

that it will reach apogee after 7.25 seconds.

Using drogue parachute descent rate

calculations you decide that the main parachute should

deploy 22 seconds after apogee.

This is how you would configure the

computer:

Set D1 and D2

Since the timing resolution is only in 0.1 second

increments we set the first delay to say 7.3 seconds. D2

will be set to 22 seconds. (see table below)

Set M1 and M2

Because of the deployment system

configuration we need to set the M1 servomotor to turn

clockwise and the M2 servomotor to turn anticlockwise when

activated. We set the positions as appropriate for the

deployment system. In this example they are just set to full

range. The On Time for both servos only requires

~1 second.

See the values in the table below.

Because the Motor On Time is set in increments of 0.16

seconds, we find that the closest value to 1 second is 0.96

seconds = 0.96/0.16 = 6. So we set the value to "6"

for parameters "8." and "b.".

Set Lost Alarm

We choose to set the alarm for 5

minutes after main parachute deployment, and we want the

sound to beep for 1 second and stay quiet for 3 seconds.

Parameter E. sets the delay in minutes, so we set

it to 5. The sound on time and off time are given in

0.25second increments so we set C. to 4 (1sec/0.25

= 4) and the d. parameter to C (3sec/0.25 = 12 = C)

|

|

D1 |

D2 |

M1 |

|

D1Tens |

D1Units |

D1Tenths |

D2Tens |

D2Units |

D2Tenths |

M1P1 |

M1P2 |

M1On |

Param

|

|

|

|

|

|

|

|

|

|

|

Value |

00 sec

|

|

0.3 sec |

20 sec |

2 sec |

0.0 sec |

0 |

32 |

.96sec |

|

|

|

|

M2 |

Lost |

|

|

M2P1 |

M2P2 |

M2On |

LOn |

LOff |

Ldly |

|

|

Param |

|

|

|

|

|

|

|

Value |

32 |

0 |

.96 |

1 sec |

3 sec |

5 min |

When finished setting the parameters, turn the power OFF.

Now if the rocket will fly with the

same setup on every launch, all you have to do for each

launch is turn on the FC and press the ARM button and

the rocket is ready to go.

In this scenario the FC is fitted to

the booster of a 2-stage rocket and will be used for

initiating the staging of the next stage and some time later

for opening a parachute on the booster. The ideal time to

release an upper stage is when the booster is travelling at

its fastest which happens right around burnout. It is also

the worst time to deploy a parachute since it could be

ripped off.

The external trigger this time is

based on a pressure switch that activates when the pressure

inside the rocket drops to 10psi above atmospheric pressure.

This means that a short time later the rocket will be

travelling the fastest as the pressure drops to 0.

This is how you would configure the

FC:

Lets assume that the time between the

sensing of the pressure drop to the time that the second

stage should be released is only

0.2s. We need to set the

D1

delay to 0.2

seconds. This means parameters "0." and "1."

are set to "0" and parameter "2." is set to "2".

M1 and M2 positions and

Motor On Times are

configured as in the previous example. And the lost alarm

functionality is turned off.

In this example we set the delay to

parachute opening to be 2 seconds after staging. We

set the "3." parameter to "0" and the "4."

parameter to "2". The "5." parameter is set to

"0".

|

|

D1 |

D2 |

M1 |

|

D1Tens |

D1Units |

D1Tenths |

D2Tens |

D2Units |

D2Tenths |

M1P1 |

M1P2 |

M1On |

Param

|

|

|

|

|

|

|

|

|

|

|

Value |

00

sec |

|

0.2 sec |

00

sec |

2 sec |

0.0 sec |

|

|

0.96sec |

|

|

|

|

M2 |

Lost |

|

|

M2P1 |

M2P2 |

M2On |

LOn |

LOff |

LDly |

|

|

Param |

|

|

|

|

|

|

|

Value |

|

|

0.96 sec |

|

|

|

When finished setting the parameters, turn the power OFF.

Now if the rocket will fly with the

same setup on every launch, all you have to do for each

launch is turn on the FC and press the ARM button and

the rocket is ready to go.

To reset the configurable parameters

back to the default factory settings do the following:

- Make sure the power

is OFF.

- Hold the PGM and ARM buttons down

at the same time and turn the power ON.

- The r

character will be

displayed. Followed by the decimal point.

character will be

displayed. Followed by the decimal point.

- Press the ARM button once more to

confirm the reset. And the decimal point will

disappear.

- After the beep, turn the power

OFF.

The default factory settings are set

up for a typical single stage 2L water rocket.

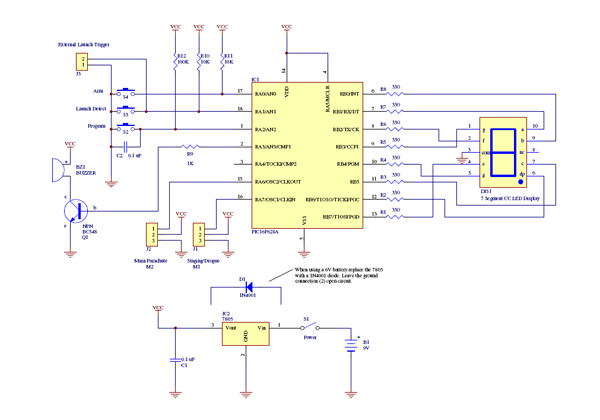

Hardware

The circuit diagram for version 1.6 is

shown in Figure 4. Central to

the design is the PIC16F628A microcontroller from Microchip.

The on-board oscillator is used to reduce the external

component count.