Building a Water Rocket Launcher

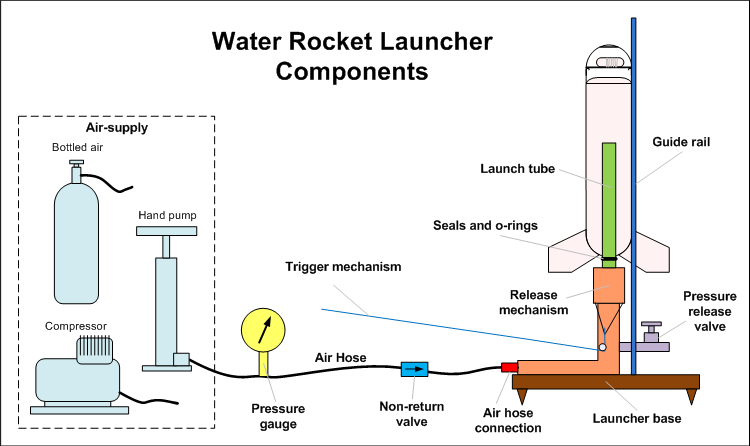

A water rocket launcher can be as simple or as complex as

you like, however, most launchers share common features.

This article describes the different components and their

function to assist you when designing your own

launcher. We provide links to examples of the various features.

Safety

Safety should be your number one priority when designing

your launcher. As your launcher will be handling compressed

air it is important to make sure all fittings are properly

rated. It is always better to err on the side of caution and

use heavier duty components as weight isn't an issue like it

is on a rocket.

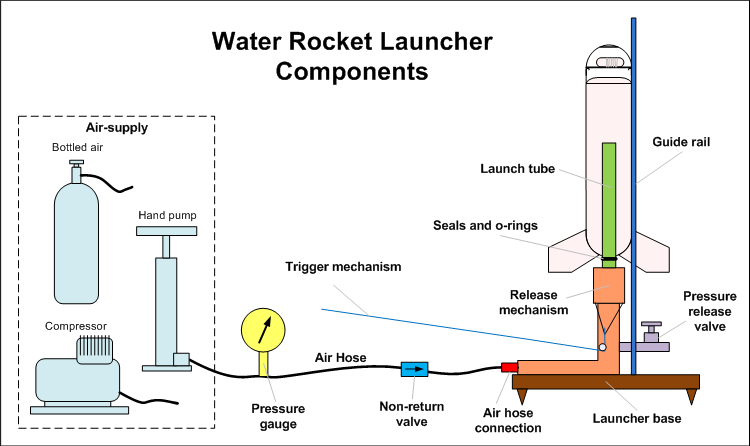

The image below shows a typical water rocket launcher

setup.

Click on the different components in the image for

more information:

Index

Air Supply

Your launcher needs to be connected to an air supply.

There are several different kinds of air supplies you can

use with the same launcher so it is best to incorporate into

your design a way to connect to different supplies as you

upgrade.

|

Bicycle

pump / car tyre foot pump - This is the easiest

and least expensive way of pressurising rockets. The

launcher's air hose connection will need to have a

tyre valve adapter in order to connect the bicycle

pump directly. Regular pumps can supply in the order

of 100-120psi. More expensive models can supply

100's of psi. |

|

Small

compressors - These require a power source such

as mains or a battery. These make filling much less

work, but watch out for cheap models as they can

easily overheat and fail. These are less portable

due to their power needs. Small compressors will

typically go to about 150psi. The larger the

rocket and higher pressures will mean the compressor

needs to run longer and will more likely

overheat. |

|

Bottled

air with regulator - This is a more expensive option for

filling your rockets, but it is the only option for

using gasses other than atmospheric air. This option

can also typically deliver higher pressures compared to normal bicycle pumps and small

compressors. You can also fill your rockets quicker

as long as air compression heating is taken into

account. Depending on the size of the tank and the

rocket's capacity you can get from dozens of

launches to over a hundred from a single fill.

Commonly used tanks include scuba, Nitrogen and CO2 tanks.

Depending on the type of tank you use, you may also

need certain certifications in order to have them

re-filled. DO NOT use combustible gasses in water

rockets for obvious safety reasons.

Note that extra care needs to be taken when

handling and transporting bottled gasses due to the

higher pressures involved.

Here is a full article on how

to use scuba tanks for your launcher. |

Pressure Gauge

You will need to have a pressure gauge attached to your

air supply line. The pressure gauge measures the internal

pressure of your rocket. It is important to know what the

rocket is pressurised to so you don't exceed the rocket's

burst pressure. It is also a useful tool when checking for

leaks.

The gauge is best located away from the launcher to allow

you to clearly see it without being too close to the

pressurised rocket. Be aware that the pressure may be

slightly different during pressurisation when the gauge is

located away from the rocket. Allowing the pressures to

equalize within the launcher, rocket and air supply hose

should give the correct reading. The delay in pressure

equalization is usually due to small air holes often used in

the hoses and its fittings. Water in the hoses can also

cause the gauge to give a delayed reading as the water moves

through the small holes.

The pressure gauge should cover the range of launch

pressures you intend to launch your rocket at. 0-200psi is a

typical range for regular rockets. Pressure gauges are often

already attached to the air-source so there is usually no

need to attach them separately.

Air Hose

The air hose and its connectors should be rated for the

intend launch pressures. The hose should also be long enough

for you to stand at a safe distance from the launch pad.

You

may be able to locate a small compressor close to the launch

pad with a short hose, and control it electrically remotely.

Seeing the pressure gauge at distance can be an issue. You

may be able to locate a small compressor close to the launch

pad with a short hose, and control it electrically remotely.

Seeing the pressure gauge at distance can be an issue.

The smaller the inside diameter of the hose the better as

you don't waste energy pressurising a larger volume of air

in the hose. A smaller internal diameter usually also means

the hose should be able to withstand higher pressures. Air

hoses can be purchased at a local retailer that sells

compressors. If you are only launching at 100psi or less

then a garden hose is a viable inexpensive alternative.

Air Hose Connection

Having a built in air hose connection allows you to

disconnect the air-supply from the launcher itself.

This

makes it convenient for transportation. The type of

connection you decide on will depend on your choice of air

hose and the air manifold/hose on the launcher. The most convenient connections are quick release ones. This

makes it convenient for transportation. The type of

connection you decide on will depend on your choice of air

hose and the air manifold/hose on the launcher. The most convenient connections are quick release ones.

Here are a number of examples:

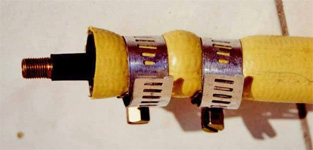

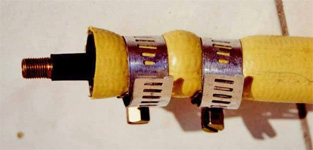

If you are connecting a bicycle pump to the launcher, you

can make a simple adaptor to connect it. It involves using

an old tyre valve taken from an inner tube and inserting it

into the launcher's hose. Then using a pair of hose clamps

to seal it all up.

source:

http://wrockets.trib-design.com/index.php?project=nick&page=other_launchers

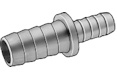

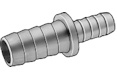

If you are trying to connect different sized hoses

together, or even extend the same size hose you can use hose

barb adaptors such as these:

Examples:

You again would use a hose clamp over the top to secure

the hose on the adaptor.

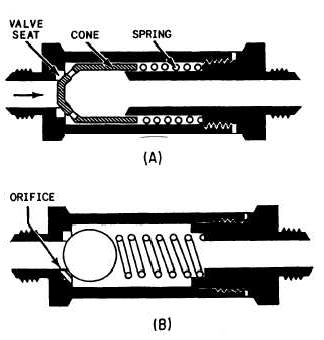

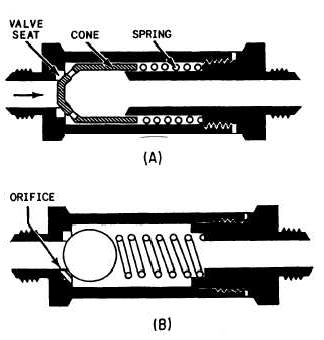

Non-return valves

Non-return or check-valves are used in

launchers to prevent water from flowing back down the air

hose. These can take many different forms. You should locate

your non-return valve as close to the rocket as possible to

keep as much water in the rocket as possible.

Here are a couple of cross sections of typical non-return

valves. One way flow is from left to right.

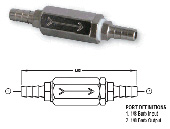

Some one way valves come equipped with hose barbs, which

makes them very easy to attach to your air hose.

Here are examples of commercially available check-valves:

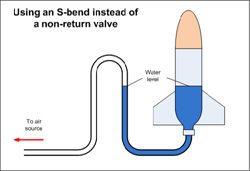

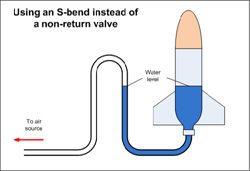

An alternative to using a non-return valve is to use an

S-bend in the air hose whose curved section is above the

water level in the rocket.

If your launcher uses a launch tube that emerges above

the water level inside the rocket then you don't need a

non-return valve.

Launcher Base

The launcher base provides a

stable framework to attach all the components to. The

launcher base should be designed to be stable and prevent

the entire rocket from tipping over when the launch string

is pulled or due to wind gust. This can be a flat board,

tripod, or any arrangement of pipe work.

Here is a typical

launcher base made from PVC piping:

http://monsterguide.net/files/2009/03/water-rocket-launcher.jpg

Here is one made from a piece of plywood:

http://www.aircommandrockets.com/images/day56/Day56_water_rocket_06_s.jpg

It is also useful to anchor the launcher to the ground

with a couple of tent pegs to prevent it from sliding when

pulling on the launch string.

Release Mechanism

The most

important part of your launcher is the release mechanism. It

is the locking mechanism that prevents your rocket from

leaving the launcher while it is being pressurised. Some

common release mechanisms include:

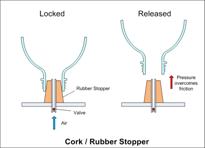

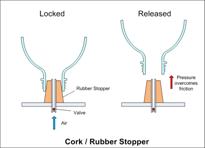

Cork/Rubber Stopper

A cork or a rubber stopper is

inserted into the neck of the bottle. Friction between the

cork and the rocket keeps it on the launch pad as the rocket

is pressurised. When the internal pressure exceeds the

frictional force the rocket is released. It is difficult to

predict when launch will occur. Although these are very

simple to make they are only suitable for fairly low

pressures. These will also give inconsistent results

depending on how hard you push the rocket onto the cork.

Examples:

|

|

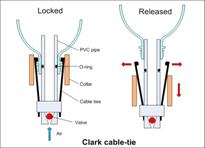

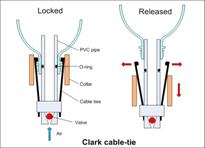

Clark cable tie launcher

A very popular launcher

named after Ian Clark who developed it. It uses cable

ties to hold down the rocket while it is being pressurised.

A collar surrounding the cable ties keeps them in place.

When the collar is lowered the cable ties open releasing the

rocket. This is typically used with fully open nozzles.

There is a huge number of Clark Cable Tie launchers

described by various rocketeers available on the net. Here

is just a few:

A variation on the Clark cable tie launcher are these

copper tube launchers that seal from the outside.

|

|

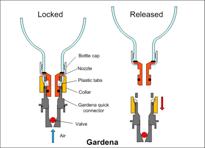

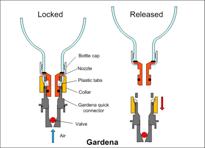

Gardena quick connector

Another popular

launcher that uses a garden hose quick connector to hold

down the rocket. The rocket is equipped with a matching

nozzle made from a garden hose adapter. Typical nozzle sizes

include 9mm and 15mm. The Gardena launcher is used

frequently for reduced nozzle sizes. You can insert/glue

smaller tubes inside the nozzle to reduce the nozzle size

even further.

Here are some examples of Gardena launchers:

|

|

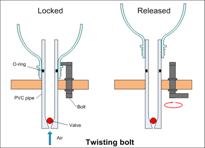

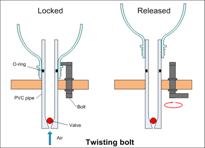

Twisting bolt

A bolt is mounted vertically in the base with a

section of the head removed. When the bolt is rotated into

the locked position the head holds the rocket down by the flange

of the bottle. Turning the bolt allows the head to release

the flange.

Examples: The first of these is a twisting bolt

variation:

|

|

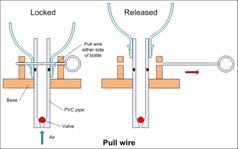

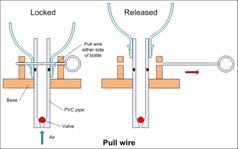

Pull wire

The pull wire launcher is based on a

similar principle to the twisting bolt mechanism, but the

bottle is held down by the flanges on either side of the

bottle with a strong wire. To launch the rocket, the wire is

quickly pulled free to release the rocket.

Examples of pull wire launchers:

|

|

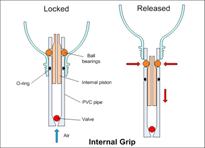

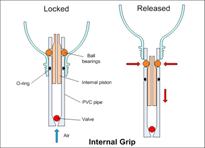

Internal grip

This is not a very common design mostly

due to more advanced construction techniques required. This

launcher holds the rocket down by the internal walls of the

rocket. In the above example a set of ball bearings are used

to retain the bottle. These are held in the locked position

when the internal piston is in the up position. Lowering the

piston allows the ball bearings to retract into the launch

tube releasing the rocket. There are a number of variants

based on this launcher design.

Another variant incorporates a compressible

rubber stopper that uses friction against the inside

of the bottle neck to both seal and retain the

rocket. Examples:

|

|

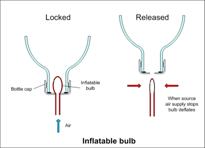

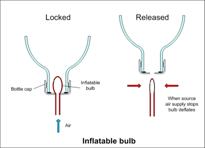

Inflatable bulb

This launch system was developed by

Antigravity Research.

http://www.antigravityresearch.com/HTMLobj-1195/This_Cant_Be_a_Launcher.pdf

It is a very simple mechanism that has a flexible bulb

fitted on the end of the air hose which is then inserted

into the nozzle. The bulb has a tiny hole in it. As air

pressure is applied the bulb swells preventing it from being

ejected and the rocket is filled through the tiny hole. When

pumping is stopped the pressure starts to equalise and the

bulb shrinks until it is small enough to fit through the

nozzle and then is ejected launching the rocket. It is

difficult to predict when the bulb will release though. This system is only suitable for small rockets due to the

size of the nozzle. Once you start filling, there is no

launch abort option. |

|

Seals and O-rings

To prevent the pressurised air and water from leaking out

of your rocket you need to use a washer or an o-ring between

your rocket and the launcher.

The type that you use will

depend on the type of launcher you are using. The higher the

pressure you want to use, the tighter the tolerances have to

be for the o-ring grooves. Always make sure that the o-ring

grooves are clean and free of scratches or burrs. Always use

correctly sized o-rings. The type that you use will

depend on the type of launcher you are using. The higher the

pressure you want to use, the tighter the tolerances have to

be for the o-ring grooves. Always make sure that the o-ring

grooves are clean and free of scratches or burrs. Always use

correctly sized o-rings.

Examples:

Rubber washers are also commonly used when sealing

rockets against the launcher. These can be typically

purchased from the hardware store. In an emergency if you really need to

make a specific sized one they can be cut from sections bicycle inner tubes.

Pressure release valves

It is a good idea to add a safety

release valve to your launcher. Sometimes it is important to

abort a launch and safe the rocket after it has been

pressurised. How this is achieved will depend on how you

configure your supply connection and where you locate your

non-return valve. The pressure release valve needs to be on

the rocket side of the non-return valve otherwise you won't

be able to release the pressure from the rocket. It is a good idea to add a safety

release valve to your launcher. Sometimes it is important to

abort a launch and safe the rocket after it has been

pressurised. How this is achieved will depend on how you

configure your supply connection and where you locate your

non-return valve. The pressure release valve needs to be on

the rocket side of the non-return valve otherwise you won't

be able to release the pressure from the rocket.

Here are some examples:

Trigger Mechanisms

Trigger mechanisms are actuators that

actually start the launch. This is typically a string

attached to the release mechanism to release the locking

lever.

|

Pull String

This is by far the most common and easiest way to launch

your rocket. The string simply connects to the release

mechanism and when it is pulled the release mechanism

activates. If the release mechanism takes a bit of force to release

you may consider using a

lever arm to help with the

activation without putting undue force on the launcher. Too

much pulling force on the launcher

could make it topple. Make sure the string is long enough to

launch the rocket from a safe distance.

The best kind of string to use is a braided nylon string.

Thin or cheap strings can easily break.

|

|

Pneumatic/hydraulic

Air or water pressure can be used to activate a

pneumatic/hydraulic piston to activate the release mechanism.

These systems are not very common mostly due to the added

expense and complexity.

|

|

Solenoid

Like the pneumatic or hydraulic pistons an electrical solenoid can provide

the required force to activate the release mechanism. These

also are not very common due to the need for a separate

power source. Use only low voltage ones. You don't want to

mix mains voltage and water.

Example:

|

|

Servo

Larger

servo motors can also be used to activate the release

mechanism. They have the advantage that they do not need a

lot of power like the solenoid, and when connected to a

receiver can be controlled through a remote control.

Example:

|

Stability

A launcher needs to have a stable base. If the

launcher is not stable it could topple when the launch

string is pulled or due to a wind gust. The last thing you

want is a fully pressurised rocket pointing horizontally.

Make sure you either have a wide base on your launcher or

that it is pegged into the ground, preferably both. If it

is not pegged to the ground you may find that the launcher

may slide as you pull the string. A couple of tent pegs is

usually enough to secure the launcher.

Portability

When designing your launcher keep portability

in mind. Is it light enough to carry a fair way to the launch site

from your car? Make sure you

can easily fold it down so that it fits in your car.

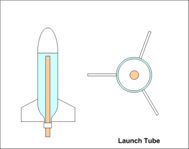

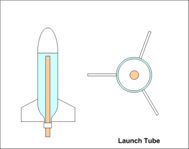

Launch tube

Adding a launch tube to your launcher can

improve the performance of your rockets. The launch tube

ideally should be as long as possible. The diameter should

be slightly smaller than the nozzle you are using. This will

minimize water loss as the rocket accelerates up the launch

tube. If the launch tube is permanently attached to your

launcher, you will be limited with the types of rockets you

can fly and what nozzles you can use. Consider making a

removable launch tube if you want to experiment with various

rockets.

Example:

Guide rails

Guide rails are very important in helping

your rocket fly vertically especially during the first part

of the flight. The guide rail keeps your rocket moving

straight before the rocket has enough air speed for the fins

become effective. There are different types of guide rails

you can choose from:

|

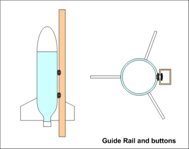

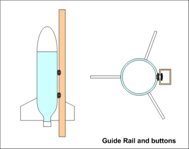

Guide Rail and buttons

These are suitable for larger

rockets and consists of a single slotted rail. The rocket is

fitted with rail buttons that slide into the rail groove.

Examples:

|

|

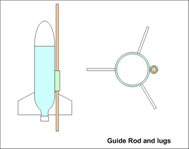

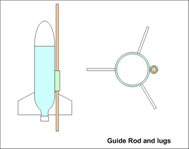

Guide Rod and lugs

The guide typically consists of a round

steel rod securely attached to the launcher. The rocket is

fitted with small lugs or short tubes that slide over the

rod. These are very common in model rockets. These are

generally suitable for smaller rockets.

Examples:

|

|

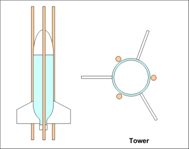

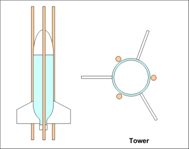

Tower

This launcher arrangement includes 3 or 4 guide rails

surrounding the

rocket without the need for the rocket to use rail buttons.

The lack of rail buttons saves weight and drag on the rocket.

If you are building a tower launcher incorporate into

your design a way to adjust the spacing so that you can put

in different diameter rockets.

Examples:

|

|

Launch tube

For certain rockets you can use the

launch tube itself as a guide rail. The rocket does not need

additional guide rails.

Examples of rockets using a launch tube as a guide rail:

|

When deciding on your guide rail arrangement think about

the types of rockets you will want to fly from your launcher

and in particular their fin arrangements. If you are using ring fins, make sure the release

mechanism will fit through the ring fin. If you are using

regular fins then make sure they will not get caught on any

part of the launcher. If you are going to use a tower

launcher then you need to consider the fin count and whether

they will all fit between the rails.

Materials

When making the launcher keep in mind that it

will get soaked from repeated launches. Stay away from

materials like MDF and chipboard which love to soak up

water. Use materials that can withstand typical outdoor

conditions. Plastic and metal are the best.

Testing

Test your launcher the same way you test your

rockets. When testing it to new pressures for the first

time use a hydro test and stand well clear and listen & look

for leaks.

Make sure you fix any leaks on your launcher. A rocket

can depressurise quite quickly while waiting to launch even

if there is a small leak.

Water Supply

A launcher can have an integrated water

supply for the rocket. This means you put the rocket dry

onto the launch pad and then fill the rocket while it is on

the pad. Pressurised air is usually used to force the water

from a reservoir into the rocket. This is typically done

prior to filling the rocket to full operating pressure. A

small bicycle pump is usually all that is necessary to force

the water into the empty rocket. A valve is needed to

isolate the water reservoir before pressurisation can begin.

Examples:

Usage Tips

- When you launch a rocket, dirt and mud can be kicked up

under the launcher and contaminate various components.

Always make sure the release mechanism and launch tube are

clean before each launch. Sand on the launch tube can be

enough to wedge a rocket so it won't fly off.

- Use silicone grease on all moving components of your

launcher. This prevents things from sticking and ensures

smoother operation. Also grease your o-rings to prevent them

pinching when fitting your rockets onto the launcher.

- Some materials degrade when exposed to UV radiation

from the sun. If you are using these materials in your

construction make sure you store your launcher out of the

sun when not in use. The little bit of exposure the launcher

gets during your launch days shouldn't be an issue.

- As you use your launcher, repeated pressurising cycles

can work-harden some components and eventually cause them to

fail. Inspect your launcher after each launch day for signs

of hairline cracks.

- When designing the entire launcher consider how you

will place the rockets on the launcher. If you fill the

rocket with water first, then how easy will it be to place it

on the guide rails? Will you be able to reach the release

mechanism easily to lock your rocket in?

- If you are using a string to launch the rocket, make sure you use a strong string that is not going

to break. The best kind of string to use is a braided nylon.

- Don't use MDF or chipboard to make the base out of, as

these will absorb a lot of water and warp and perhaps fall

apart. Use only water proof materials.

- The type of release head your launcher uses will depend

on your rocket design and chosen nozzle types. If you plan

on flying lots of different rockets with different nozzle

types, you may want to consider making swappable release

heads for your launcher.

References and other launcher examples:

There are about as many launchers as there

are water rocketeers. Here are just a few examples of their

work:

|

You

may be able to locate a small compressor close to the launch

pad with a short hose, and control it electrically remotely.

Seeing the pressure gauge at distance can be an issue.

You

may be able to locate a small compressor close to the launch

pad with a short hose, and control it electrically remotely.

Seeing the pressure gauge at distance can be an issue.  This

makes it convenient for transportation. The type of

connection you decide on will depend on your choice of air

hose and the air manifold/hose on the launcher. The most convenient connections are quick release ones.

This

makes it convenient for transportation. The type of

connection you decide on will depend on your choice of air

hose and the air manifold/hose on the launcher. The most convenient connections are quick release ones.

The type that you use will

depend on the type of launcher you are using. The higher the

pressure you want to use, the tighter the tolerances have to

be for the o-ring grooves. Always make sure that the o-ring

grooves are clean and free of scratches or burrs. Always use

correctly sized o-rings.

The type that you use will

depend on the type of launcher you are using. The higher the

pressure you want to use, the tighter the tolerances have to

be for the o-ring grooves. Always make sure that the o-ring

grooves are clean and free of scratches or burrs. Always use

correctly sized o-rings.  It is a good idea to add a safety

release valve to your launcher. Sometimes it is important to

abort a launch and safe the rocket after it has been

pressurised. How this is achieved will depend on how you

configure your supply connection and where you locate your

non-return valve. The pressure release valve needs to be on

the rocket side of the non-return valve otherwise you won't

be able to release the pressure from the rocket.

It is a good idea to add a safety

release valve to your launcher. Sometimes it is important to

abort a launch and safe the rocket after it has been

pressurised. How this is achieved will depend on how you

configure your supply connection and where you locate your

non-return valve. The pressure release valve needs to be on

the rocket side of the non-return valve otherwise you won't

be able to release the pressure from the rocket.