|

1. |

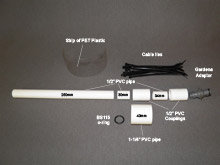

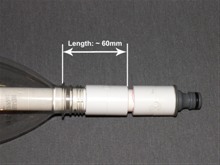

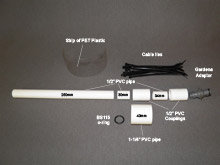

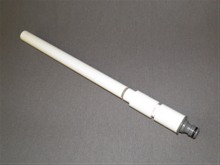

Cut a 1/2" PVC pipe into the following 3 lengths:

30mm, 34mm and 250mm. Try to cut them as square as

possible. Two ends of these will form the o-ring groove

so you want to have nice square

edges. TIP: If you are having trouble cutting square

ends for the o-ring groove, you can often use the two

square ends of

the PVC pipe as it came from the shop. |

|

|

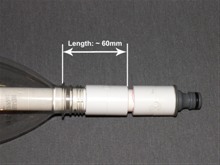

2. |

Remove one o-ring from the Gardena

double male adaptor as you won't need it. Keep it as a

spare for future projects. Rough up the inside of one of the PVC

couplings with sand paper. Use a fairly coarse sandpaper

something

like 120 grit. |

|

|

3. |

Mix up some epoxy and apply it around

one side of the Gardena adaptor, and also coat the inside of the

coupling. Use a generous amount of epoxy as you want it

to fill the gap. It's best to use the

24-hour epoxy

rather than the weaker 5-minute epoxy.

|

|

|

|

|

4. |

Stand the adaptor on its end and put

the coupling over the top. Gravity will cause the glue

to settle at the bottom making a seal and joining the

two components together. Let it cure overnight.

You can use the

other coupling at this stage to help it stand up. |

|

|

5. |

While waiting for the Gardena adaptor

to cure, you can make the o-ring groove on the launch

tube.

A simple way to make the groove in the PVC

pipe is to insert a smaller diameter pipe into it. While this may sound easy, there aren't many

plastic pipes readily available that snugly fit inside the PVC

pipe. Resist the temptation to hammer oversized

tubes into the PVC pipe which can lead to fine cracks in

the PVC causing it to fail under pressure. If you have

access to a lathe then you can machine down a bar of

plastic to the right size. |

|

|

6. |

If you can't get your hands on the correct size pipe

or a lathe then there is a simple alternative you can

use and you already have it at home. This technique is

shown in this tutorial.

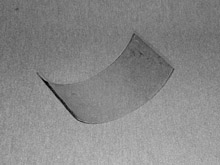

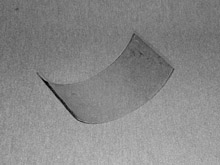

Cut out a flat strip from a PET bottle. You

want the strip to be about 65 mm (2.5 inches) wide and

180mm (7 inches) long.

Sand both sides of the PET strip to

give the glue a better surface to adhere to. Use the

same coarse sandpaper as before. |

|

|

7. |

Roll up the strip tightly until it fits inside

the tube. You want to make sure you have at least 4-5

wraps. If you have more, then that's even better. When

you release it, the strip will expand to tightly fit

inside the tube. If you are happy that the strip will

fit, take it out again. |

|

|

8. |

Rough up the inside of the launch tube

and the 30mm section of PVC pipe with sandpaper.

|

|

|

9. |

For the next few steps you will want to

use rubber gloves as it can get pretty messy. Apply a coat of the

24-hour epoxy

to the inside of both pieces of pipe. |

|

|

10. |

As you roll up the strip coat the inside of

it with

epoxy. You don't need a lot. Spread the glue all the way

to the edges. When you roll it up, the glue will spread. |

|

11. |

Roll it up the rest of the way and coat

one end of the roll that will go into the

launch tube. Again you do not need a lot of glue. Insert the strip about half way into the launch tube. |

|

|

12. |

Now coat the other end of the strip roll with

epoxy and insert it into the

30mm section of PVC pipe. Slide the two together until

you have the correct size gap for the o-ring. This

should be 3.5 - 4mm. See

notes below for details of the

correct o-ring

groove size. As you bring the sections together some

glue will be squeezed into the groove. Just wipe off all

the excess with a tissue both inside the groove and any that

may be on the PVC pipe. Image on the right shows the glue wiped

clean. |

|

13. |

Stand the launch tube on it's end and

let it cure overnight. |

|

|

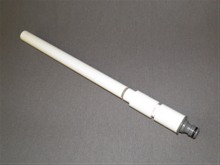

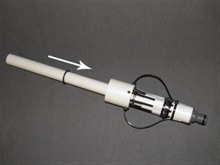

14. |

Using PVC cement, glue the launch tube

into the top coupling, and glue the 34mm section of PVC

tube between the two couplings. Make sure that the gap

between the two couplings is wide enough to accept the

head of the cable ties you are using.

Let the glue cure.

|

|

15. |

Put a bottle on the launcher and

measure the distance between the flange and the edge of

the gap between the two couplings. This will help you

position the tape in the next few steps |

|

|

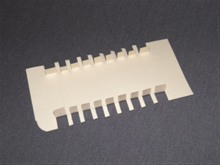

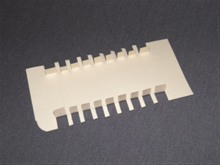

16. |

To get even spacing between the cable

ties we use a piece of cardboard with cut outs bent

over. If you are happy with just eyeballing the spacing

you can skip this step.

We chose to use 8 cable ties in this design as that

is sufficient for the desired range of pressures. (See

testing experiments at the end of the tutorial.) |

|

|

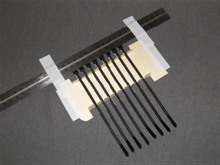

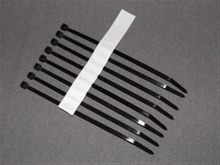

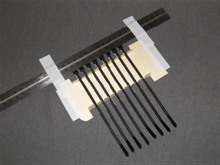

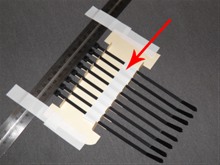

17. |

Tape the cardboard template to the

table and put the cable ties in the gaps. Tape a ruler

along the heads to keep them aligned, We use the tabs on

template to stop them moving down. If you are not using

a cardboard template you can just use another ruler under the

heads. Apply a piece of tape to the cable ties so that they

are held together. You want to make sure the outside of

the tape isn't more than the distance you previously

measured. (The tape

should not cover the gap between the couplings.) |

|

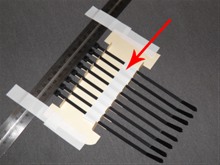

|

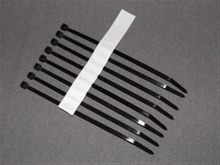

18. |

Take the cable ties out of the template

and flip them over and apply a second layer

of tape to the other side. Have a piece of tape extend

past the last of the cable ties. This will help in

attaching the cable ties to the launcher. |

|

|

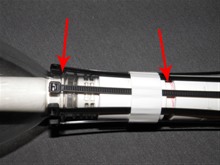

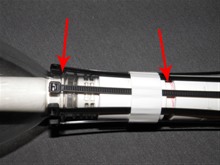

19. |

Wrap the cable ties around the upper coupling and

secure with the end of the tape.

Make sure the heads sit snugly against the flange on

the bottle and that the tape does not cover the gap

between the couplings. |

|

|

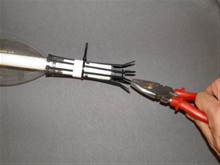

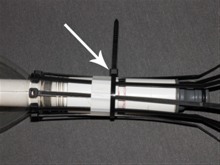

20. |

Wrap a single cable tie around all the

cable ties and tighten it just enough to

apply some pressure to the cable ties.

Thread a bottle onto the launch tube

and rest it against the top of the coupling.

Now you can adjust the position of the

individual cable ties so that they rest firmly against

the flange. The tape will allow you to move them with a

little effort. You may want to use a pair of pliers to

help with this step. When you are happy with the fit for all

the cable ties, tighten the wrapped cable tie. |

|

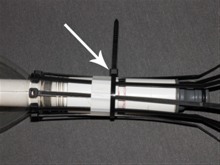

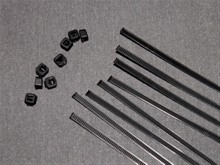

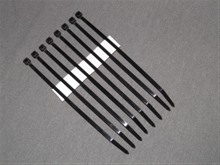

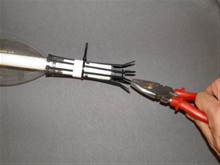

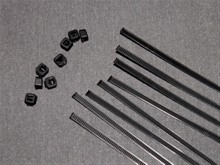

21. |

Cut the heads off another set of cable

ties. |

|

|

22. |

Thread the heads individually onto the cable ties

that are in place. Slide them all the way up until the

heads sit in the groove. These will help grip the

individual cable ties to stop them from sliding up when

the launcher is pressurised. |

|

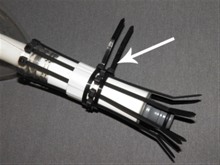

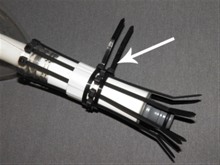

|

23. |

Wrap a second cable tie on the other

side of the heads and tighten it. You can now trim all the cable ties. |

|

|

24. |

Drill 4 holes equally spaced near the

bottom of the collar. The holes should be big enough to

pass a cable tie through. |

|

|

25. |

Insert 2 cable ties as shown on

opposite sides and tighten them so that the heads are on

the outside. |

|

|

26. |

Bring the two ends together on the

lower coupling and secure with a piece of tape. |

|

27. |

Add another cable tie

over the top and tighten it. These two

cable ties act as springs to keep the collar up before

the rocket is pressurised. |

|

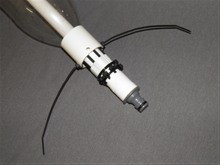

|

28. |

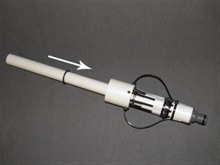

Slide the o-ring over the launch tube

into the o-ring groove. |

|

|

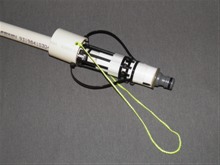

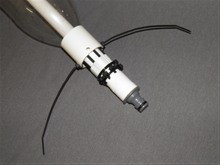

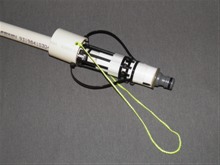

29. |

Tie a loop of string to the other two

holes. These will be connected to your pull string.

Use strong braided nylon for the string to make sure it

does not break.

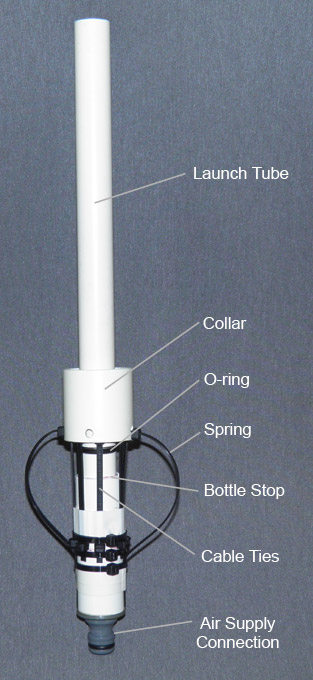

The launcher is now ready. Here the launcher is

plugged into our regular Gardena launcher.

You should first pressure test your launcher

from a safe distance to make sure all the glue and cable

ties hold. |