|

1. |

Remove the labels from 2 bottles and

clean the glue residue off with turpentine. Clean off

any remaining turpentine with a dry cloth or tissue.

The bottles should be the same diameter as the rocket. Choose bottles with straight sides.

Most will have a small ridge or raised section before

they transition into the curved part of the bottle. This

makes splicing the bottles much easier.

Most bottles

will have this ridge on the bottom section as well.

Which one you should use depends on the bottle. For

these 1.25L bottles we like to use the top one. |

|

2. |

Cut the bottom section off the

bottles. We like to use a Stanley knife to rough cut the

bottle first and then scissors to trim it to size. |

|

3. |

Use caution when cutting with a knife

as the bottles are soft and the knife can easily slip. |

|

4. |

Leave about 5mm of the top ridge when

cutting off the top sections. This

will help with the splicing. If you leave a longer

overlap you may have problems easily sliding one sleeve

other the other. TIP: When cutting bottles like this and you

are using right handed scissors, hold the bottle in your

left hand and cut along the bottom edge. You will get a

straighter and more even cut. |

|

5. |

Prepare the alignment jig. This jig can

take many different forms but we found it easy to just get a

can from the pantry whose diameter is just smaller than

the bottles and wrap it in a manila folder until it

is

the right size. You may need to do several wraps

depending on how close a fit your can is.

Tape the folder together so that you get a nice tube.

Leave the can in the folder as this serves as a heavy

and stable base while working on the fairing. |

|

6. |

You may already have a

tube or a section of pipe that is the right diameter so

just use that instead.

This particular can-and-folder alignment jig we have actually been using for

quite a while and have used it with the

ring fin alignment jig. |

|

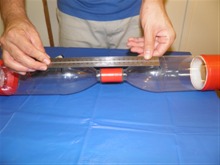

7. |

Put both bottle sections onto the jig

so that the lower one has the little ridge at the top.

If you find that it is hard to slide the top one over

the bottom one, try swapping them around, sometimes the

bottles can have slightly different diameters. |

|

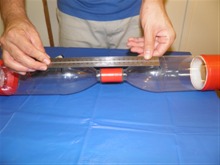

8. |

Run a thin bead of PL premium around

the bottom of the upper bottle section and then push the

two together. You can clean up the edge with a skewer

stick. We sometimes use the tip of the skewer stick to

force the glue into the join if it wasn't forced in all

the way when pushing the two sections together.

NOTE: The join doesn't have to be air or water tight

so it's okay if there are some bubbles or the glue

hasn't penetrated the join all the way in some sections.

You can probably use other glues as well, as this

section isn't pressurised and hence does not need to be

as strong, however, you don't need a lot of PL to make a

strong join. |

|

9. |

Wrap the join in electrical tape to

hold it together while the glue dries. Electrical tape

is a good option because it is flexible and conforms

itself well over the join. |

|

10. |

Slide the entire fairing off the jig

and let it cure for 24-48 hours depending on the

humidity.

When sliding it off, lift it by the lower sleeve.

TIP: Because of the long cure time, we

normally prepare several fairings at the same time while

we have all the tools on hand, and that way we have

spares when they are needed.

|

|

11. |

Next we need to measure how long the

fairing should be. A good fairing will have a tight fit

when the rocket is screwed together. This helps keep the

rocket segments aligned.

Slide the fairing onto the

bottle and mark where the fairing rests on the

curved section. |

|

12. |

Do the same for the other side of the

rocket. |

|

13. |

Screw the rocket together

and measure the distance between the marks. |

|

14. |

Mark the fairing with the correct length.

You will want to cut off the top ridge. |

|

15. |

Draw a line all the way around. Use a piece of paper

to get a nice parallel line. |

|

16. |

First cut around 5mm from the line. If you

don't trust yourself to cut a nice parallel line, then

you can draw several lines next to each other using the

paper technique above. Try the fairing to see how well it

sits. If it is too tight, trim it by a couple of mm and

try again. Repeat this step until the fairing is the

right length. You will now know how long to make all

subsequent fairings. If you switch bottle types, you

will have to perform this step again. |

|

17. |

The fairing is now ready to use. You can mount cameras,

altimeters, rail buttons etc. inside the fairing. This

will make it easy to swap the mounts for the different

devices between rockets. Simply unscrew the rocket and

remove the fairing and fit it to another rocket. If you

make the fairing too loose and want to stop it

from rotating on the rocket, you can add a wrap of

electrical tape at either end of the fairing where it

comes in contact with the rocket. If the fairing is fairly tight this

is generally not necessary. |