|

1. |

This stager is designed to work with a

standard 9mm Gardena nozzle. If you don't have one

already, you will need to make the nozzle first. Here's

how: Making a Gardena

nozzle. |

|

2. |

Here are the materials you will

need. Make sure that the Gardena quick connector you

are using will not slide into the FTC. There is a flange

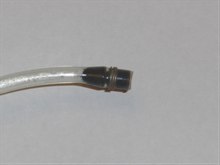

on the quick connector just behind the thread. The

flange diameter should be bigger than the FTC diameter.

Some cheaper brand quick connectors are slightly

narrower and could potentially slip inside the FTC. |

|

3. |

Cut two lengths of the T8 FTC. One

should be ~70mm long and the other ~35mm.

When you cut these

out, you need to make sure that the edges are as square

as possible. Use a piece of paper wrapped around the outside

and mark along the edge. Carefully cut along the lines.

If the edges are not square then the sustainer will not

sit straight on the booster. You can use scissors to cut

the FTC along the line. |

|

4. |

Roughly cut the FTC piece off with a

craft knife, and then trim to the marked line with

scissors. |

|

5. |

Cut the smaller FTC tube lengthways with a

pair of scissors. |

|

6. |

Remove the orange collar from a Gardena quick

connector by inserting 3 strips of PET plastic

underneath the collar's locking tabs, and then pulling

back on the collar.

Remove the spring and re-assemble the collar making

sure you have the white locking tabs in place. You will need 4

of these springs altogether so you can remove these from

old quick connectors. Make sure the springs are

identical in size.

At this point test to see if the sustainer nozzle

locks all the way into the quick connector. If it doesn't, you can modify the

quick connector as shown here:

Launcher Fix |

|

7. |

Sand the internal hole of the Gardena

quick connector to allow the epoxy to grip better. |

|

8. |

Put a piece of Blu-Tack, plasticine or

modelling clay on the workbench and stand the

Gardena connector on it's end (orange collar pointing up) so

that the Blu-Tack blocks the central hole. Mix up some epoxy and carefully pour it through the open

end. Pour enough epoxy

in so that it is about 5-10mm deep. It's better to use the

stronger epoxy rather than the 5 minute stuff.

Let the glue fully cure for 24 hours. |

|

9. |

If the cap is the kind with a removable

seal then remove it from the bottle cap and cut a hole

in it as shown. The bottle cap may not have a

removable seal or may be one of the

type C caps then you don't need to do this step. |

|

10. |

Assuming the outside diameter of your

tubing is exactly 5mm, drill a 5mm hole

straight through the top of the cap. It does not need to be

exactly on center.

NOTE: The tube needs to be a snug fit in this hole.

You should not be able to slide the cap freely on the

tube. If the hole is too big, get a new cap and drill a

smaller hole. |

|

11. |

Now use the same drill bit and drill a hole in

the epoxy glue of the Gardena quick connector. |

|

12. |

Cut about a 220-230mm length of the

clear tubing with a pair of scissors. Find an old

plastic ball point pen that has a conical pen tip. You

may need to look through a number of them, as some have

small ridges on the inside. You may also find other

small plastic cones as part of other components. As long

as it is small enough to fit in the end of the tubing

then it should be good. The conical section needs to

have smooth internal walls to allow the valve to seal

properly. |

|

13. |

Push the cone section into the tubing

as far as it will go. This is easy to do if you grip the

end of a pop rivet or something similar in a vice and

then push the pen tip over it.

NOTE: It is important to have the pen tip securely

pushed into the tubing. If it is loose, it may get

pushed out under pressure. |

|

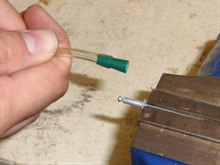

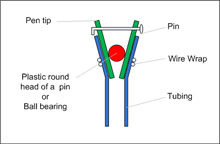

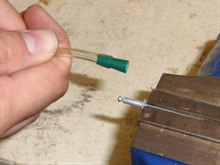

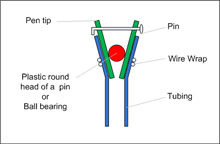

14. |

Cut the head off a pin with a plastic

round head, or alternatively find a ball bearing of the

right size and make sure it fits inside the pen tip cone

section. It should be big enough not to fall through

the smaller hole of the cone.

Heat another pin and push it through the plastic

walls of the cone so that the round pin head can move up

and down, but cannot fall out. |

|

15. |

Push the pin through, cut it with a

pair of wire cutters a couple of mm from the pen tip,

and bend it with pliers to stop it from falling out. |

|

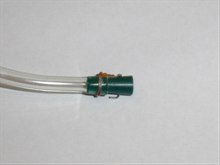

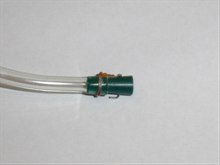

16. |

You can wrap a couple of wire loops

over the tubing and tighten with pliers. |

|

17. |

This is how the non-return valve should

look. |

|

18. |

Wrap a length of tape around one end of

the longer section of FTC. Here we are using glass

strapping tape about 10mm wide. Wrap enough of the tape

until the outside diameter of the tape is the same as

the orange collar diameter. |

|

19. |

Cut out two slots as shown in the

FTC body. These should be wide enough to let the tubing

move freely inside them. Cut them

elongated so the tubing has room to move as the spring

compresses.

NOTE: The location of these slots will depend on how

your springs sit. I assemble the stager first without

the tubing and then draw on the outside of the FTC where

the holes need to go. The upper hole should be as high

as possible and the lower hole should be as low as

possible. This allows the tubing to sit more vertically

in the cap and the quick connector giving a better seal. |

|

20. |

Insert the free end of the tubing

through the quick connector and pull it all the way

through until the non-return valve is sitting snugly

inside the quick connector against the epoxy.

Thread 3 of the springs completely onto the tubing,

with the first spring pushed all the way up to the

flange of the quick connector and the fourth spring should be only partially threaded.

Let the tubing emerge out the side of the 4th spring.

Now insert the springs and tubing into the FTC body,

allowing the tubing to emerge from the bottom hole. This

is a little fiddly but not difficult. After all the

springs are inserted, make a loop in the tubing and

rethread it back through the upper hole and back down the center of the FTC body.

Pull the tubing out as far as it will go (the loop

will tighten) and insert the tubing in the top of the

bottle cap.

You can now push the cap into the FTC body. The caps and

FTC we use fit snugly together. Your FTC may be a little

bigger or cap smaller, so at this point you can wrap a

bit of tape around the cap to give a tight fit. You may

need to try a few caps otherwise, until you find one

that works well. |

|

21. |

For the next step we need to widen the

free end of the tubing so it cannot come out of the cap.

For that we use the plastic tip from another pen. This is a very

common type of pen, with a metal tip fitted in a plastic

adaptor with the ink straw inserted from the other end.

Pull out the metal tip with pliers, and remove the ink

straw. You'll be left with the hollow plastic adaptor.

This is a nice size for the tubing, and the tapered

and makes it easy to insert into the tubing.

Alternatively you can use something like a round glass

bead with a hole in it and push it into the end of the

tubing. |

|

22. |

You can again use the pop rivet or

similar in a vice to hold the pen tip. |

|

23. |

Push the tubing over the pen tip until

the end of the tubing is level with the end of the pen

tip. |

|

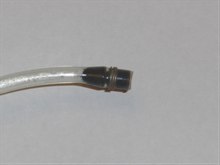

24. |

Now wrap a couple of loops of wire over

the end to prevent the pen tip from being pushed out

under pressure. |

|

25. |

Push the tubing back through the cap

until the pen tip is pushed up snugly against the hole

in the cap. The tubing loop will loosen again.

Screw the cap onto the booster bottle and tighten.

Now push the FTC body down over the cap until it rests

on the bottle flange. This will help support the sustainer

during acceleration.

NOTE: There needs to be quite a bit of friction

between the cap and the FTC body so that the spring does

not push the cap out. |

|

26. |

Take the smaller piece of split FTC and

slip it over the rolled up tape at the top end of the

FTC body. Tape this down with the

electrical tape. Make sure you tighten the tape really

well and wrap it several times. You also need to pay

special attention to the alignment of the split FTC so

that it is not at an angle to the FTC body. |

|

27. |

NOTE: The next step is very

important, and it helps to get someone to help you.

Place the nozzle into the stager and push down the

inner part of the quick connector compressing the spring

until the flange rests on top of the FTC body.

While holding down the inner part of the quick

connector, slide the orange collar all the way up until

the nozzle is locked. Now wrap electrical tape around

the orange collar where it overlaps the short

piece of FTC. What you are trying to achieve is to

attach

the orange collar to the split FTC.

Once you tape it down firmly, (use a few wraps) you

can release the nozzle, and the inner part of the quick

connector should spring out again.

There will be approximately a 10mm gap in the split

FTC. This gap cap be used to place a locking tab in

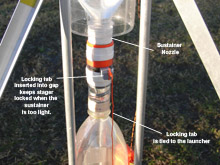

the stager. (see below) (This image was taken from our other stager and

is why the lower tape is white in this image) |

Because of YouTube's 10 minute limit, we have broken the

construction tutorial into two parts.

Because there are so many varieties of springs and quick

connectors it is difficult to predict how much force your

springs will give.

You should get a reading of 800grams or more. If it is much

less than that, you may find that the stager fails to open in

flight. (We found out the hard way). This means your sustainer

needs to weight at least 800 grams to keep the stager locked.

This is not unreasonable for a small sustainer considering it

may weigh 200 grams with 600mL of water. If the fully fuelled

sustainer weighs less than than, you can still use this stager

with a locking tab. (See below)

You may find that you need to adjust the spring tension of

the stager. This can be achieved by trimming the bottom of the

FTC body and pushing it down against the bottle flange again.

This will increase the spring tension. Trim a couple of mm

at a time.

To use the stager, simply fill the booster with water and

place it on the launch pad. Fill the sustainer with water and

push the sustainer nozzle into the stager and let the

sustainer's weight lock the stager.

The stager does not need to be mounted on top of the booster.

You can run the length of tubing to another part of the rocket

to supply air to the sustainer.