|

|

|

|

last updated: 9th November 2024 - Day 236 - Launch Tubes #2 |

|

|

|

Splicing Bottles AS#5 |

|

#235 - Coming Soon |

|

#234 - Coming Soon |

|

#233 - Coming Soon |

|

#232 - Coming Soon |

|

#196 - Coming Soon |

|

#193 - Coming Soon |

|

#172 - Coming Soon |

|

|

|

|

Back to Top Construction Index

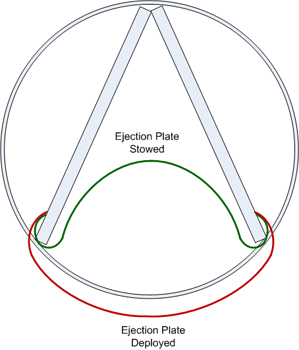

Using

a felt marker, mark out the hole for the parachute. The hole should be a

little wider ~3mm than the two sides of the V. This

allows space for the ejection plate to flex. Vertically

the hole should be just smaller than the inside edges of

the circles.

Using

a felt marker, mark out the hole for the parachute. The hole should be a

little wider ~3mm than the two sides of the V. This

allows space for the ejection plate to flex. Vertically

the hole should be just smaller than the inside edges of

the circles.