|

|

|

|

last updated: 9th November 2024 - Day 236 - Launch Tubes #2 |

|

|

|

Splicing Bottles AS#5 |

|

#235 - Coming Soon |

|

#234 - Coming Soon |

|

#233 - Coming Soon |

|

#232 - Coming Soon |

|

#196 - Coming Soon |

|

#193 - Coming Soon |

|

#172 - Coming Soon |

|

|

| FLIGHT LOG | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Day 150 - Rocket Salvos, Foam Experiment | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Date: 14th

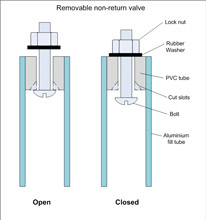

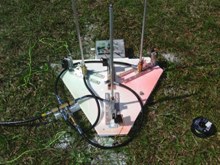

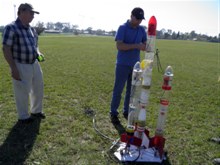

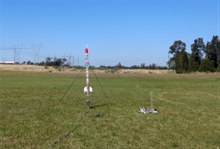

September 2014 Location: Whalan Reserve, NSW, Australia Conditions: Sunny, calm, 22C Team Members at Event: PK, GK, Paul K, and John K. Rocket SalvosFor this launch dad had the idea to fly a number of rockets from the new cluster launcher, but rather than launching them all at the same time as you do in a drag race, we were going to launch them one at a time in quick succession. The middle one would go first and film the others with a couple of cameras as they overtook it. We had to update the firmware on the launcher to give us 200ms delay steps that we could adjust out in the field. A problem with doing it this way was that the air manifold that normally equalizes the pressure between the boosters had to be modified to prevent air escaping through the fill tubes of those rockets that had already launched. We added simple removable non-return valves to the tops of the fill tubes so that later we could reuse the same fill tubes for launching regular boosters. Here is a diagram of the removable non-return valve. Launch DayA beautiful cloudless and windless day awaited us when we woke up and as we headed out to the launch site. 10 minutes from the site we drove into really dense fog. This was going to be good, because it usually means that the morning is going to be nice and calm, and sure enough within half an hour the fog had burned away, leaving that great cloudless sky with virtually no wind. Salvo 1 - The rockets were set-up on the cluster launcher easily. We didn't use any guide rails so not all the rockets were pointing directly vertically. The sliding nozzle seats allowed us to move them back far enough to give clearance for the 12 fins now on the pad. We put 1L of water in each of the smaller rockets, and 1.5L and foam in the middle rocket. The timing was set so that the second rocket would get released 800ms after the first. The others would then get released at 400ms intervals. As we started pressurising the rockets, one of them self launched at around 10-20psi and went up maybe 30 feet before crashing nose first into the ground. The nosecone fairing was crushed, but was easy to pop back out, and since the deployment mechanism still worked fine we set it up again. We believe that we simply forgot to lock this rocket into the launcher, Ooops. We locked it in this time, armed it, and as we started pressurising the parachute deployed from the same rocket. This time I forgot to twist the wires properly on the break wire. Double Ooops. I put the parachute back, properly secured the break wire, and we were able to go up to 120psi without any further problems. Launch was good, although without the guide rail the main rocket veered of to one side a little, followed shortly by the other 3 rockets. It was a great sight to see and all 4 rockets deployed their parachutes at apogee landing back on the mowed grass. It was time to download the on-board video, but to my embarrassment I noticed that one of the cameras had its tiny lens cap still on. Triple Ooops! At least the other camera caught good action of the rockets going up. The way it veered off course actually gave it a good view of the remaining rockets. We will paint the lens cap orange to make it easier to notice that it is still on. Salvo 2 - We set the rockets up again on the pad, but this time we adjusted the timing so that the second rocket launched only 400ms after the first, and then the others followed 200ms apart. This time the launch went well without any issues or lens caps and the timing was a lot more impressive. We got good onboard video again from both cameras. Salvo 3 - The next salvo was also set up in the same way with the same timing as salvo #2. Again the launch went well and all the rockets came back safely under parachute. This time while reviewing the video on the #11 cam, we saw that it stopped recording after about 1 minute while the rocket was still on the pad. We saw similar behaviour with it when Daniel flew it on his remote control plane. There the video also cut out after about a minute. I'm not sure what the cause is, but will need to do further testing. The other camera got a good shot of the launch, so we were happy with that. We had 8 cameras covering this launch. 2 x on-board, 1 at ground level looking up, 1 on a tripod giving static shot of the pad, 2 x tracking the rockets, 2 x still cameras. Here is a highlights video from the day from multiple angles: Foam ExperimentThe last launch of the day was a test to see how well foam generation works during pressurisation with a large nozzle. We filled the rocket with a water and foam mix, but this time we doubled the amount of bubble bath in the mix. One problem with this test was that the launch tube went almost all the way to the top of the first spliced pair, and therefore there was no way to fill the rocket without filling the launch tube first. If it was a little lower we could have used the funnel tube to fill around the launch tube. For best performance the launch tube should be hollow. Even as we poured the solution in we noticed that not a lot of foam was forming in the lowest bottle as we see normally. This was a little odd, but we didn't pay much attention to it. When we started pressurising the lowest bottle foam started getting generated so it was good for a while but as we kept going, the foam level started decreasing, so by the time it was time to launch the rocket, there was virtually no foam left! We had no idea what was causing this. Later that night, we thought that it perhaps may have been another additive that was causing the foam to collapse. We had used a good dose of silicone grease on the bottle to get it to slide onto the o-ring. The launch tube was a tight fit and as the bottle was slid down that had coated the launch tube as well. When we got back we performed a small experiment of putting some foam and water in a bottle and shaking it up. The foam held well inside the bottle. We then added a little silicone grease and shook it up again, and sure enough the foam started collapsing quickly. After a while there was very little foam left. So off to check with the interwebs and it turns out that silicone is often used as an anti-foaming agent due to its low surface tension. Here are a couple of references: http://www.machinerylubrication.com/Read/255/oil-foam and http://www.dowcorning.com/content/foodbev/antifoam.asp So lesson learnt, we'll use less silicone grease in foam powered rockets. Conversely, this may be a useful additive when using the Jet Foaming technique that generates foam during flight, but leaves a lot of foam in the rocket. The silicone may help prevent too much foam from staying behind in the rocket. Here is a video showing the observed launch, as well as the de-foaming experiment.

So all up a great day for flying rockets with a total of 13 launched, plus the one that self launched. Flight Details

|