Date: 14th April 2007 11:30am -

2 pm

Location:

Backyard

Conditions: Partly

sunny.

Rockets:

|

Name |

Capacity |

Notes |

|

Polaron IV |

8.8 L |

This is the rocket body without

any recovery system or fins, used

purely for testing performance. |

Team Members at

Event:

PK, GK, AK, John K and Paul K.

Number

of Firings: 12

More static tests were performed to

measure and compare the trust from straight

through nozzles and Convergent-Divergent

(CD) nozzles. CD nozzles are also sometimes

referred to as De Laval nozzles.

The static test setup was identical to:

Day 31

The thrust curve data shown below was for

a rocket with the following parameters:

| Parameter |

Value |

Notes |

| Capacity |

8.8L |

4 x 2L bottles joined

neck to base with a 8mm Robinson

coupling. The actual volume of each of

the 2L bottles is 2210mL |

| Water |

2050ml |

For all tests.

The rocket used our Jet Foaming

technique to create foam. |

| Bubble

bath solution |

50ml |

For all tests. |

| Pressure |

100 psi |

For all tests (air) |

Because we were going to do quite a few

experiments, we didn't want all that foam

going into the garden so we collected the

water and in a large plastic tray under the

test rocket. We used up almost an entire

bottle of bubble bath for these tests.

Nozzle design

We manufactured two CD nozzles: one with

a 7mm throat and the other with a 9mm

throat. In both instances the expanding

section was 4 degrees from the centerline.

The expanding shape was conical since that

is much easier to manufacture. See diagram

at left. We didn't want to design an optimal

nozzle shape, we just wanted to see how much

of difference an expanding nozzle makes, if

at all, and only then would we attempt to optimise it.

7mm and 9mm Nozzle

Profiles (click to enlarge)

The shape of the divergent section was

based on video footage of previous tests

where we measured the expansion rate of the

foam. We made the slope of the divergent

section less than the average slope in order

for the expanding foam to have some sort of an

"effect" on the nozzle.

We made sure that the baseline straight through

nozzles had exactly the same hole as the

minimum diameter (throat) in the CD nozzles.

This turned out to be 7.1mm and 9.2mm

respectively. This way we eliminated the bias due to

different sized holes.

Analysis

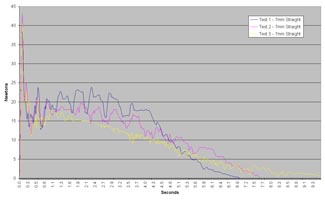

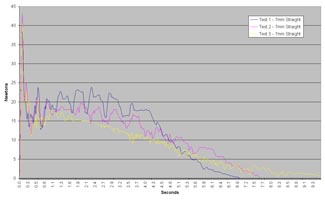

We ran three tests with the 7mm nozzle in

order to establish a baseline for the test.

The first test looks quite out of place

compared to the other two tests, and this we

traced back to forgetting to put in the

locking pin that prevents the dampner

container from moving. We believe the

fluctuations were due to this.

7mm straight through nozzle thrust curves

(click to enlarge)

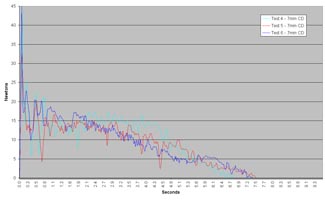

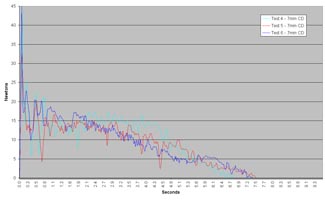

When we performed the 7mm CD nozzle tests we

again repeated it 3 times in order to reduce

experimental errors and get a sense of

repeatability of the experiment.

7mm CD nozzle thrust curves (click to

enlarge)

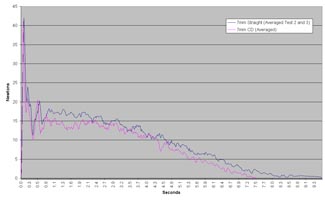

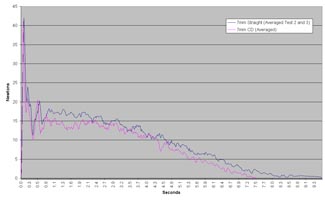

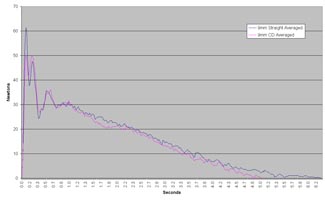

Now we average the two sets of data

(ignoring test 1) we get the following

graph:

7mm straight through and CD nozzle thrust

curves

averaged and compared (click to enlarge)

We did not include test 1 in the average

because the measurements weren't reliable.

When we compare the straight through

nozzle performance to the CD nozzle

performance we see that with the 7mm CD nozzle

the total impulse is only

83% of

the straight through nozzle.

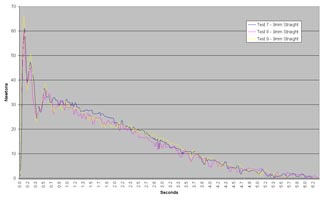

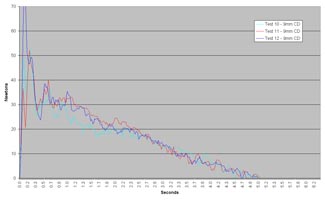

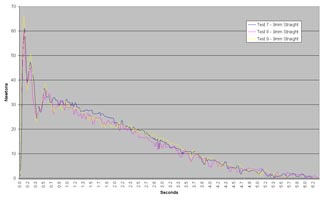

We then switched to the 9mm straight

through nozzle and ran another 3 tests. All

three tests showed similar results which

helped confirm that the test was

reproducible fairly accurately.

9mm straight through nozzle thrust curves

(click to enlarge)

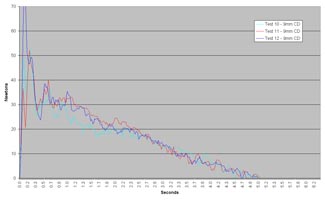

Following that we performed another 3

tests with the 9mm CD nozzle. Again the

results were fairly similar to each other.

9mm CD nozzle thrust curves (click to

enlarge)

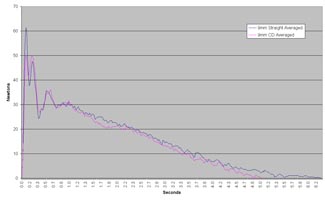

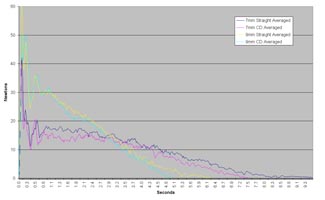

When we average the above

results for the straight through nozzles and

CD nozzles we get the following graph:

9mm straight through and CD nozzle thrust

curves

averaged and compared (click to enlarge)

The thrust curve shapes were almost

identical for the straight through nozzles

as well as the CD nozzles, however, it is

quite evident that the total impulse is

lower for the CD nozzles. In fact the 9mm CD nozzle

produced only 92.6% of the total impulse of a

straight through nozzle.

The results for both nozzles were

disappointing as we were hoping to see some

sort of improvement, however, the result was

not unexpected.

We must stress that these tests were done

at only 100psi and the results may be quite

different at much higher pressures.

Currently we do not have the technology to

make these tests at the high pressures we

think it is likely to make a difference

(1000psi+) Antigravity used their CD nozzles

with pressures over 1000psi.

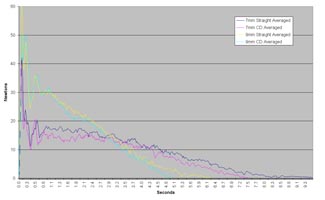

The following graph shows the averaged

results for 7mm and 9mm nozzles. You can see

that the 9mm nozzles produced more total

impulse than the 7mm nozzles and would

therefore be better to reach higher

altitude.

7mm and 9mm nozzles averaged and compared

(click to enlarge)

Should others want to do

further analysis of the data, the data for

both nozzles is available in spreadsheet

format here:

Thrust_Curves_140407.zip

Thoughts

- It may be that because the foaming

agent affects the water's surface tension

it is causing the foam to "stick" to the

surface of the nozzle causing greater

friction. Different nozzle materials may

have a different effect on friction.

Perhaps the length of the expanding

section has an effect on the loss of

efficiency?

- It may be that the foam also isn't an

ideal foam and that a lot of loss of

impulse is due to normal water being

ejected. CD nozzles have a negative effect

when only water is used.

- It may also may be possible that the

shape of the nozzle has to be quite

different compared to what was tested

here.

- One thing that is not evident from

these results is that the total thrust

does not end with the end of the thrust

curve. In fact, a decaying amount of

thrust usually continued for

another at least another whole second. But the thrust

was less than the weight of the rocket and

so is not shown on the graph. In real life the rocket would actually

be decelerate less slowly during this time due to drag

and gravity then if

the thrust had ended completely.

- Some of the variance in the results is

also due to how the water was distributed

between the lower and upper bottles for

the Jet foaming to be effective. It is

difficult to accurately control the ratio

of the water in the two bottles.

- Because both the 7mm and 9mm CD

nozzles gave a lower performance than the

straight through nozzles, we will put

further testing and development of CD

nozzles on the back burner until we can

reach much higher pressures and then test

again. The other reason is that

translating the video frames to

spreadsheet is very laborious and

electronic logging needs to be utilised.

Test Record

|

Test |

Rocket |

Pressure (PSI) |

Total Impulse(N-s) |

Notes |

| 1 |

Polaron IV |

100 |

97.0 |

Calibrated test, 2050ml water, 50ml

bubble bath 7mm straight through nozzle. |

| 2 |

Polaron IV |

100 |

94.9 |

Calibrated test, 2050ml water, 50ml

bubble bath 7mm straight through nozzle. |

| 3 |

Polaron IV |

100 |

82.0 |

Calibrated test, 2050ml water, 50ml

bubble bath 7mm straight through nozzle. |

| 4 |

Polaron IV |

100 |

77.0 |

Calibrated test, 2050ml water, 50ml

bubble bath 7mm CD nozzle. |

| 5 |

Polaron IV |

100 |

70.7 |

Calibrated test, 2050ml water, 50ml

bubble bath 7mm CD nozzle. |

| 6 |

Polaron IV |

100 |

72.5 |

Calibrated test, 2050ml water, 50ml

bubble bath 7mm CD nozzle. |

| 7 |

Polaron IV |

100 |

97.3 |

Calibrated test, 2050ml water, 50ml

bubble bath 9mm straight through nozzle. |

| 8 |

Polaron IV |

100 |

91.2 |

Calibrated test, 2050ml water, 50ml

bubble bath 9mm straight through nozzle. |

| 9 |

Polaron IV |

100 |

95.5 |

Calibrated test, 2050ml water, 50ml

bubble bath 9mm straight through nozzle. |

| 10 |

Polaron IV |

100 |

82.8 |

Calibrated test, 2050ml water, 50ml

bubble bath 9mm CD nozzle. |

| 11 |

Polaron IV |

100 |

89.6 |

Calibrated test, 2050ml water, 50ml

bubble bath 9mm CD nozzle. |

| 12 |

Polaron IV |

100 |

90.7 |

Calibrated test, 2050ml water, 50ml

bubble bath 9mm CD nozzle. |

|