Date: 18th

November 2007,

6:30am - 8:30am

Location: Denzil Joyce Oval

Conditions:

20 degrees C, Easterly at 0-10km/h,

cloudless sky

Team Members at

Events:

GK, PK, Paul K, John K

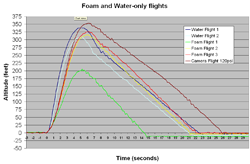

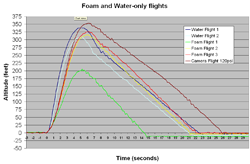

We had an excellent day of launches this

weekend. The weather was ideal with very

little wind and well behaved rockets. On

this day we were able to finally fly

multiple flights to compare foam and

water-only using altimeter data.

Flight Day Events

Foam vs. Water-Only

Here are the results of the comparison

flights for the day. The data was exported

from the altimeter software and imported

into Excel where the data was aligned in

time and

altitude offsets adjusted. The only difference between

the flights was that bubble bath was added

to the water for the foam flights. The pressure, capacity, nozzle

size and weight all remained the same.

The rocket parameters:

| Capacity |

5.3 Liters |

| Pressure |

110 psi (7.6 bar) |

| Nozzle |

Straight through 9mm |

| Width |

90 mm |

| Weight |

537 grams |

| Water |

1.25 Liters |

Observations

While these tests are by no means

conclusive, we did learn a couple of

interesting things.

- Water-only altitudes were 338

and 308 feet, although on video

review of the second water-only

flight it didn't go quite as vertical so

the average between the two is closer to

330 feet.

- The two valid foam flights were

316 and 326 feet and both

were quite vertical. The average was

321 feet.

- This means that foam resulted in

2-3% less altitude.

- The simulation predicted altitude

for water only was 320 feet

(Taking a guess at the drag coefficient

and nozzle efficiency values).

- This implies that foam has less

performance, however, after the last foam launch I capped the

rocket so the residue foam would not leak out in the

car. Hours later when the residue foam condensed

back into water I was surprised to find that

there was approximately 80ml of water in

the rocket. That is at least another 80

grams that had to be carried to that

altitude.

This amount does not include all the water that drained out of the

rocket on the way down and when we

carried it back to the launch pad. There may have been

perhaps just as much or more water still left in the

rocket when it reached apogee that did not

contribute to the thrust as a reactive mass!

- This means that the foam powered

rocket lofted

another perhaps ~150 grams. This

represents ~12% total water mass!

Simulations predict a water-only rocket

with 150 grams more should achieve only

~ 246 feet compared to 321'

foam flight. (23% more)

- The question now is how do we make use of

all that dead weight during the thrust

phase?

- From previous

thrust measurements we found that

foam had 14% less total impulse,

however, this only resulted in 2-3%

less altitude. Most of this is likely

due to the reduced drag on the rocket

because it travels slower for longer.

If we can improve the total impulse for

foam, and utilise the extra dead weight

we are likely to be able to improve the

altitude ... more experiments needed we

think.

- The noise in the altimeter data on

descent is likely due to the parachute

door flapping near the altimeter port

hole.

Flight Computer Progress

Development on the new flight computers

is also progressing well with most of the

design now finished. And software still

needing to be completed. The new flight

computer will have a remote control for

setting and arming so that no one needs to

be near the rocket. It will also completely

control the altimeter's recording. Supporting two separate

RC servos it can control staging and parachute deployment,

or a drogue/main parachute combination. A

small speaker is included to provide audible

computer state

information.

We will publish full details again once

this is complete and flight tested.

I also discovered a design issue with the

existing flight computers when powering them

from 6V. The voltage regulator voltage

wasn't being regulated to the desired level

because the input voltage was not high

enough. When powered by a 9V battery there

was no issue. Instead of the 5V we were

getting only 4.35V which was still enough to

power everything but meant the servo wasn't

achieving its full power potential. This

issue has now been resolved.

Crushing Nosecone

After destroying a number of payloads

over the last few months, we wanted to redesign the nosecone

and payload section so that if a parachute

failed to open, the payload would have a

reasonable chance at surviving the impact. On

the

water rocket forum

Richard and Cliff

had some good suggestions how to go

about it. Speeds of 150-200km/h are typical

on impact.

The shock absorbing nosecone design we

finally settled on is an extension that

tapes onto an existing payload nosecone. It

consists of a aerodynamic sleeve made from a

PET bottle with half a ping pong ball at the

top to give it the proper streamlined shape.

It is

filled with a block of soft foam. The

sleeve has a number of long slots cut along

its length to allow it to open up during

impact. The foam inside the sleeve is

designed to compress against the existing

nosecone. Because the nosecone extension can

move it will also compress the air inside it

against the existing nosecone further

helping to absorb the shock. When that

reaches its limit the existing payload nosecone will

also crush further absorbing the shock.

On impact there will still be significant

damage to the nosecone, but the payload

components should be reasonably well protected.

The altimeter is also housed in its own foam

padding.

This nosecone extension weighs 37grams

and can be easily removed when flying high

performance missions, and put back

when doing tests or other experiments.

We have now flown 7 missions with this

nosecone extension, but thankfully we

haven't needed to use it yet.

The layout within payload section has

also been redesigned, with the battery now

in the middle of the bulkhead "V" behind the

parachute and the RC servo is now mounted

sideways just above the flight computer.

Both are much more securely attached.

The parachute attachment point has also

been moved further up the rocket so that it

always lands tail first. This reduces the risk of damage to

the payload section when landing under

parachute.

Bottle Reinforcing

During the week we had another go at

reinforcing bottles to take higher

pressures. We have tried this technique

before but the last tests were only

for a single bottle and due to problems with

the pressure test setup we didn't quite achieve what we wanted. There was also a

slight issue with one of the outer sleeves

sliding off.

This time around we have improved how the

sleeves fit and can no longer slide off.

This test also included joining together two

reinforced bottles with a Robinson

coupling, because ultimately we want to

build higher pressure multi-bottle rockets.

We did a hydrostatic pressure test on the

two joined bottles up to 200psi. We held it

there for about 20 seconds and let the

pressure out. There were no leaks and upon

close inspection we found that there were no

visible stress marks around the bases or

necks of the bottles. This was very

encouraging as it means that the bottles

could have probably held at least 230psi+.

It also means a launch pressure of at least

200psi can be used.

Detailed steps of the reinforcing

procedure are now in the

construction section.

Misc

We have expanded the ground support

equipment we bring to the launch site. Dad

made a portable sun shade that goes up

quickly, and we now also bring a fold up

camping table. The table makes it easier to

work on rockets.

I also purchased a new

laptop last week so that we can have a

computer at the launch site for downloading

videos from the in-flight cameras, and

downloading & viewing altimeter data as

well. Eventually we will be able to

make flight computer software changes in the

field. The computer can run

simulations on the spot so we know what to

expect with rocket configuration changes before launch.

Normally these

really aren't an issue when launching at the

local park, but as we plan on launching more

powerful rockets, we will need to go a lot

further from home and launch events will

take up most of a day instead of one or two

hours.

Goals

Our goal in the medium term is to develop

a fleet of 4 or 5 different rockets and

corresponding spare parts so that we can

continue to do experiments when weather

allows instead of loosing good launch days

to repairs.

A longer term goal is to move to the

higher power rockets and do experiments in

the higher performance range. At this point

in time it looks like the NSWRA (NSW

Rocketry Association) is re-forming and

getting access to great launch sites as well

as the proper permissions from authorities.

When everything is sorted we hope to join in

the new year. Having local contact with

experienced pyro rocketeers will be a great

benefit as many materials, payloads and

recovery systems are very similar in both

rocket disciplines.

Flight Details

| Launch |

Details |

| 1 |

|

Rocket |

|

J4

IV |

|

Pressure |

|

110 psi |

|

Nozzle |

|

9 mm |

|

Water |

|

1.25 L |

|

Flight Computer |

|

V1.3.2 - Setting:

"8" |

|

Payload |

|

Altimeter |

|

Altitude / Time |

|

338' / 22.4 s |

|

Notes |

|

Very good flight,

with good deploy and good landing. |

|

| 2 |

|

Rocket |

|

J4

IV |

|

Pressure |

|

110 psi |

|

Nozzle |

|

9 mm |

|

Water |

|

1.25 L |

|

Flight Computer |

|

V1.3.2 - Setting:

"8" |

|

Payload |

|

Altimeter |

|

Altitude / Time |

|

308' / 20.9 s |

|

Notes |

|

Very good flight.

Flew in a big arc. good landing. |

|

| 3 |

|

Rocket |

|

J4

IV |

|

Pressure |

|

110 psi |

|

Nozzle |

|

9 mm |

|

Water |

|

1.25 L + foam |

|

Flight Computer |

|

V1.3.2 - Setting:

"8" |

|

Payload |

|

Altimeter |

|

Altitude / Time |

|

206' / 14.3 s |

|

Notes |

|

Good flight, long

arc path with very smooth foam

trail. Good landing. |

|

| 4 |

|

Rocket |

|

J4

IV |

|

Pressure |

|

110 psi |

|

Nozzle |

|

9 mm |

|

Water |

|

1.25 L + foam |

|

Flight Computer |

|

V1.3.2 - Setting:

"8" |

|

Payload |

|

Altimeter |

|

Altitude / Time |

|

316' / 21 s |

|

Notes |

|

Excellent foam

flight. Nice and vertical. Very good

deploy and good landing. |

|

| 5 |

|

Rocket |

|

J4

IV |

|

Pressure |

|

110 psi |

|

Nozzle |

|

9 mm |

|

Water |

|

1.25 L + foam |

|

Flight Computer |

|

V1.3.2 - Setting:

"8" |

|

Payload |

|

Altimeter |

|

Altitude / Time |

|

326' / 22 s |

|

Notes |

|

Another excellent

foam flight. Almost identical to the

one above. |

|

| 6 |

|

Rocket |

|

J4

IV |

|

Pressure |

|

120 psi |

|

Nozzle |

|

9 mm |

|

Water |

|

1.25 L + foam |

|

Flight Computer |

|

V1.3.2 - Setting:

"8" |

|

Payload |

|

Altimeter, Camera |

|

Altitude / Time |

|

Unknown |

|

Notes |

|

Very good camera

flight. Altimeter failed to record

flight because I forgot to turn it

on. |

|

| 7 |

|

Rocket |

|

J4

IV |

|

Pressure |

|

120 psi |

|

Nozzle |

|

9 mm |

|

Water |

|

1.25 L + foam |

|

Flight Computer |

|

V1.3.2 - Setting:

"8" |

|

Payload |

|

Altimeter, camera |

|

Altitude / Time |

|

353' / 26.1 s |

|

Notes |

|

Excellent camera

flight. Altimeter recorded good

data. Good landing. |

|

| 8 |

|

Rocket |

|

Graviton |

|

Pressure |

|

120 psi |

|

Nozzle |

|

9 mm |

|

Water |

|

800 mL + foam |

|

Flight Computer |

|

V1.3.1 - Setting:

"A" |

|

Payload |

|

Altimeter, camera

internal to payload, Lego blocks. |

|

Altitude / Time |

|

Unknown |

|

Notes |

|

A very good flight,

but jet foaming was not achieved as

water drained to lowest bottle

before launch. Good landing. |

|

|