Date: 6th January 2008

Location: Workshop

Conditions:

Indoors

Team Members at

Event:

GK and PKThis week I

thought I'd share one of the things we have

been working on in the background - the

Katz Stager. It's a staging mechanism

based on a different principle to friction

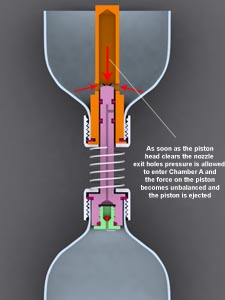

types such as a crushing sleeve, or the

locking types such as a Gardena mechanism.

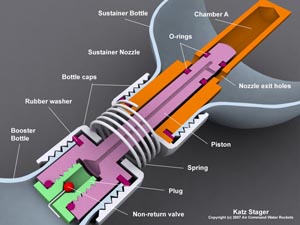

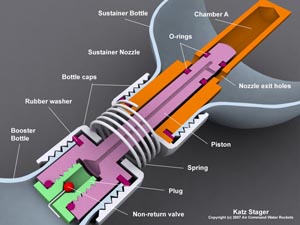

Katz Stager

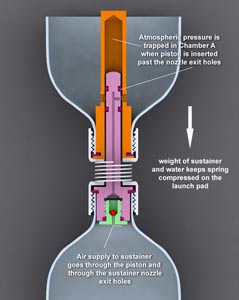

The key to this system is trapping

atmospheric pressure in a part of the mechanism

to ensure that there is no net force acting on the mechanism to separate the

stages. A spring is used to separate the

stages after burnout.

Main Components

The staging mechanism consists of the

following components:

(Click on images to see more detail)

- Piston - The main component

in the booster providing the air supply

to the sustainer.

- Sustainer Nozzle - The main

component in the sustainer, traps

atmospheric pressure and acts as a

nozzle.

- Plug with non-return valve -

screwed into the base of the Piston. It

prevents air and water from coming back into

the booster.

- Caps - Regular bottle caps

used to hold the nozzle and piston in

place.

- Spring - Used to provide the

separation force between the sustainer

and booster just after burnout.

How It Works

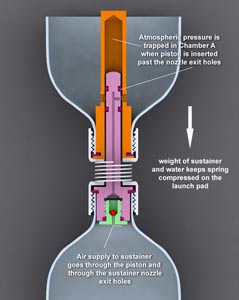

1. The sustainer is partially filled with

water and the nozzle is screwed on.

Note: Water has been omitted from the

diagrams for clarity. (It also made it

easier to make the diagrams)

2. The booster is filled with water and the

piston is screwed on. The booster and

sustainer are turned upside down and fitted

together. This is so that water does not

enter chamber A in the sustainer. (A little

bit of water is okay). When the top o-ring

of the piston moves past the nozzle exit

holes, atmospheric pressure is trapped in

chamber A.

3. When the combination is turned back

upright, the weight of the water and the

sustainer keeps the spring compressed and

prevents the spring from pushing the booster

and sustainer apart.

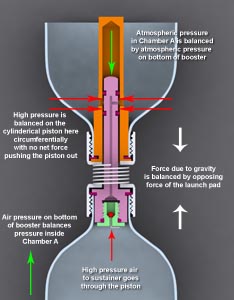

4. The piston o-rings prevent water/air from

leaking into chamber A and also out past the

piston.

5. The piston has a small hole that emerges

from between these o-rings and lines up with

one of the nozzle exit holes. This small

hole continues through the center of the

piston to the plug that contains a

non-return valve made from a bent pin, much

like you might find in a crushing sleeve

mechanism.

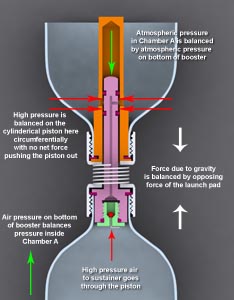

6. When the booster is pressurized, the

higher pressure in the booster opens the non-return valve

and air is allowed to flow into the

sustainer through the piston.

7. Now as the pressure grows inside the

sustainer, the forces on the piston are only

circumferential and cancel each other out (Red

arrows at top). There is no net force on the

piston pushing it out of the sustainer.

This is because the only area of the

piston that can exert a force to push it

out is the top of the piston and that

remains at atmospheric pressure. This is

the key to the Katz stager. This means

that pressure inside the sustainer can

be very large, yet the piston can remain

free moving as long as the pressure in

chamber A remains at atmospheric levels.

There is no need for friction or locking

mechanism to keep the sustainer from

flying off.

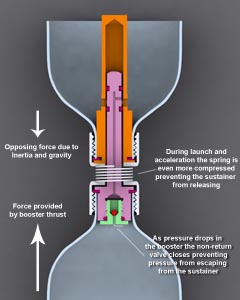

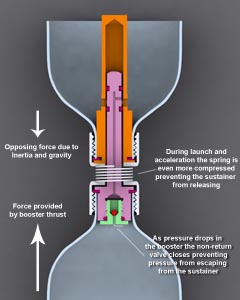

8. During launch the inertia of the

sustainer, working against the thrust of the

booster, keeps the spring even more

compressed preventing the mechanism from

staging.

9. As the pressure drops inside the booster

the non-return valve in the piston keeps the

pressure from escaping from the sustainer.

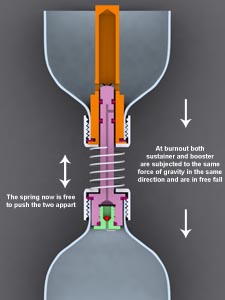

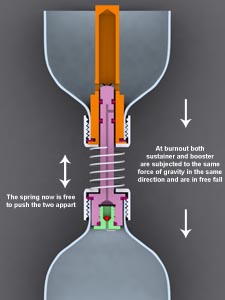

10. As the thrust from the booster drops to

zero, the sustainer and booster are

essentially in free fall and the booster is no

longer providing an opposing force to the

sustainer. (As

the ground was providing while still on the

launcher, and the thrust was providing

during the boost phase) The spring is

then free to start forcing the booster

and sustainer apart.

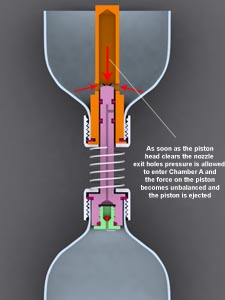

11. As the piston starts to move out of the

nozzle and the top o-ring moves past the

nozzle exit holes, the sustainer pressure

enters chamber A and now acts in full force

on top of the piston and forces it out of

the nozzle. Similar to the way a launch tube

works.

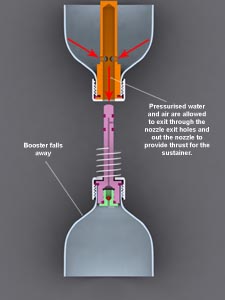

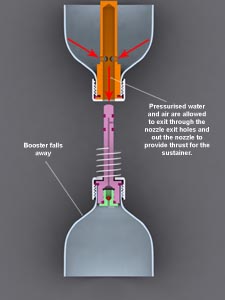

12. When the piston is forced completely out

of the nozzle staging has occurred and the

sustainer can go about its business. The

combined cross-sectional area of the nozzle

exit holes is much larger than the nozzle

cross sectional area so there is minimal

restriction of flow of water and air. (In

real life the nozzle exit holes are a lot

lower than in the diagram so water does not

collect around the base of the nozzle.)

You are probably asking yourself why such

a complex mechanism is needed, when a

crushing sleeve is so much simpler? We

wanted to bring another design idea to the table

that may help spark other ideas based on

this concept. Here are some advantages and

disadvantages.

Advantages

- The sustainer pressure can be very

large.

- Other than the spring there are no

moving parts.

- Relatively lightweight and compact design.

- A long thin nozzle is not necessary as

with a crushing sleeve.

- The nozzle diameter can be quite

large. Perhaps as much as 20mm. Large

diameter crushing sleeve mechanisms are

difficult to build.

- There is potential to use a De Laval

nozzle with this design.

Disadvantages

- Components need to be fabricated -

cannot be made from household items.

- The spring tension needs to be

chosen appropriately for the sustainer.

Current Status

We have built a prototype

of the nozzle and piston and have fired it 3

times horizontally with air only. This was

to test to see if Chamber A would retain the

atmospheric pressure. We used our hand to

push the sustainer and booster apart in the

tests. The piston was a little more stiff to

push out than what we would have liked, but

softer o-rings and a little more silicon

grease should help that out.

What's Next ?

We need to find the right spring with

the correct force to separate the two and then

test fly the mechanism.

Concept Extensions

This mechanism could equally be used as a

launch mechanism on a launcher. The rocket

could be pressurized to high pressure

without the need for a strong retaining

mechanism. A small lever would replace the

spring and would serve to push the two

apart in order to launch the rocket.

With the described mechanism, you could

not use a launch tube, however, the design

could be easily modified to place the

chamber at the top of the rocket (such as in

the neck of the upper bottle) and the launch

tube would work as the piston, trapping the

atmospheric pressure in the neck of the top

most bottle.

|