|

Date: 19th May 2008

Location:

Workshop

Team Members at Event:

GK and PK.

Repairs

All the plastic retaining tubes have been

removed from the Polaron V main stage. On

inspection one other tube was cracked (other

than those that were shredded) . Because of

the forces involved we didn't want to take

any more chances with plastic, so we

replaced them with thin walled brass tubes.

Although adding a little more weight, they

should be up to the job. We will need to do

some tests first though before giving them

the all clear. We are giving the PL a week

to fully cure. Other than the tube

replacement the rest of the rocket and

boosters are ready to go.

Acceleron has been mostly repaired

with the exception of the staging mechanism.

Over the last month or so we have been

working on yet another staging mechanism,

and with the repairs needing to be done for

Acceleron's stager we decided to

complete it and put on Acceleron IV. We

still have a long way to go with it, and

need to do more testing, but so far the

development has been going well. I will post

full details once it has flown. It is a lot

more compact and lighter than what was used

on Acceleron previously. Since we are

rebuilding the staging mechanism it was a

good opportunity to upgrade the Tachyon

sustainer. We are building a completely new

sustainer that has ~30% more capacity, more

streamlined shape and new parachute

deployment based on V1.5 of the flight

computer. The fin section now integrates a

ring fin with 4 smaller conventional fins.

The ring fin struts are made from 6mm carbon

fiber tubing and act as supports for the

sustainer during the boost phase.

The top part of the pressure chamber

consists of a spliced 1.25L pair of bottles

Robinson coupled to a special 1.25L bottle.

We have a couple of bottles (they don't sell

them anymore) that are very streamlined

ideal for tail cones of rockets. We Robinson

coupled it as opposed to splicing it so that

we can use Jet Foaming in this rocket. The

nosecone also comes from a slightly

different bottle compared to what we

normally use. The nosecone has about a 20%

longer curved section making it more

streamlined. The sustainer will carry both

the altimeter and camera.

22mm Tornado Couplings

I briefly discussed the new tornado

couplings in the

last update.

Since then, I ordered 10 of the

3/4" BSP sockets from

Philmac,

but at $4 each they are a little pricey.

They arrived a few days ago and dad

got on the lathe and re-threaded all of

them. By the end he was cranking them out

every 15 minutes. We have 13 couplings

altogether now and want to use them on a

number of projects. An upgraded Acceleron

booster

will need at least 6 of them.

The large bore couplings will enable us

to do two things. Use long launch tubes and

allow us to experiment with bigger nozzles.

The Robinson couplings we have been using

were only 8mm and this caused a choking

effect when used in combination with a

larger nozzle. Having larger nozzles will

allow us to build bigger rockets, as the 9mm

nozzles can only provide a certain maximum

thrust for a given pressure. To lift heavier

rockets we will need to use bigger nozzles.

New Rocket

As the bottles trickle in from friends

and family, we have been making up a

stockpile of the spliced pairs of bottles,

both 1.25L as well as 2L ones. The 2L pairs

use 5 bottles each so that is a lot of

lemonade that has to be processed. 2

bottles make up the pressure chamber, 1

bottle for the splice sleeve and two bottles

are used for the reinforcement rings around

the neck of the bottles. We also use the

cylindrical sections from the last two

bottles to make up the inter-bottle

aerodynamic sleeves.

These spliced pairs work well with the

new couplings allowing us to assemble

various configurations of rockets or

boosters.

We have assembled a new rocket to fly

this weekend using 3 spliced pairs and 3 of

the couplings. The removable fin assembly

was taken from Hyperon and the nosecone and

deployment system are taken from the Tachyon

III sustainer. We pressure tested the rocket

to 130 psi without leaks. The rocket has a

capacity of ~7.5 liters.

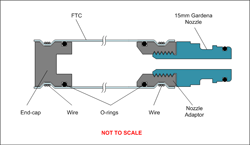

FTC tests

In the background we have been working on

some FTC tests. The primary reason for

looking at FTC is that we want to use it to

make some upper stages of rockets. We bought some

T8 6-foot lengths quite a few months ago,

but only now are we getting to doing

anything with them. The FTC only has an

average wall thickness of 0.36mm which is

pretty thin.

We made an end-cap out of some

PVC we had on hand and the nozzle is

based on a 15 mm Gardena nozzle. The one we

bought from the local hardware store came

with an outside thread. We machined an

adaptor with a matching thread that fits

snugly inside the FTC. We then epoxied the

nozzle inside the adaptor. The seal for the

end-cap and nozzle is provided by an o-ring

that sits against the FTC. Just behind the

o-ring is a groove that allows us to shrink

the FTC into it to hold the end-cap and

nozzle in place. We copied this technique

from

Urie's water rockets.

To secure the end-cap and nozzle we wrap

a couple of loops of thin fencing wire

around the FTC just over the groove. We then

apply heat from a heat gun to the FTC while

applying tensile stress to the wire. This

allows the wire to deform the FTC into the

groove. We then let it cool down and twist

the wire closed.

For the first test we used a 1 foot

length of the FTC and secured the end-cap

and nozzle at either end. When we first

heated the end of the FTC we kind of forgot,

that other parts of the FTC may also get hot

and we ended up buckling a part of the FTC

past the end cap. Oops. Since it was going

to be a pressure test, the slight buckle

didn't worry us. On all subsequent heating

we filled up the FTC with cold water and

that prevented the FTC from shrinking where

we didn't want it to shrink.

We then hydrostatically tested the FTC to

190 psi before the FTC split. We were

happy that the end-cap and nozzle held and

that there were no leaks. One of the nice

things about attaching the nozzle and

end-cap in this way (without glue) is that

we can reuse them for other tests or actual

rockets.

We then hydrostatically tested another 1

foot length of FTC, but this time wrapped

it with one layer of fiber glass strapping

tape. We also added a number of extra wraps

of the tape around each end right near the

o-rings to help with the seal. As we reached

230 psi the end-cap flew out of the FTC. It

looks like the groove in the end-cap was not

deep enough and the wire probably loosened

where it was twisted. This allowed the

end-cap to slide past the wire.

There was no

damage done, and we will reused the same

length of FTC in another test, but this time

with a deeper groove in the end-cap. We want

to see how far we can take the reinforcing.

The single layer of tape added 7grams to the

1 foot length of FTC. I believe Urie's

water rockets filled the outside groove

where the wire is with Epoxy, and this may

be a good way to keep the wire from

unraveling.

Our first goal is a launch pressure of

200psi, so I think it is well within the

techniques we are using for reinforcement

and attachment of the nozzle and end-cap.

Miscellaneous

I bought a new heat gun (Metabo HE2000)

a couple of weeks ago. We've been using a blowtorch for

shrinking bottles until now, but it was

always a bit of a hassle having to light it,

and get refills for the gas cylinder. The

heat gun has good range of temperature

settings and air speeds.

After a couple of months of slow

development the new Flight Computer V1.5

software is almost finished. The full write up

and user manual will be

available on our site shortly.

|