|

Date: 15th

April 2010

Location:

Workshop

Conditions:

Warm 24C.

Team Members at Event:

PK and

GK

Fiberglassing

Two weeks ago we took our first plunge

into fiberglassing pressure vessels for our

rockets. We know that eventually in order to

get peak performance we will need to be

using more expensive composite materials,

but at least this way we can limit the costs

while learning the necessary techniques. We

have previously made some fiberglass

components such as nosecones and fins but

have not tried reinforcing bottles.

We are using

West

Systems 105 Epoxy and 206 hardener as

the resin. For the first tests we used

200gsm E-glass wrapped on a spliced-pairs of

bottles. The spliced-pair acts as the

internal air bladder. We only spliced these

with the Sikaflex 11FC to give an air tight

seal, but we are relying on the fiberglass

to prevent the two ends from flying apart.

After wrapping the bottles we set them up

on an improvised rotisserie and placed them

next to a series of light bulbs to cure the

epoxy faster. We measured the temperature

carefully so that it was around 30 C at the

surface of the bottles to prevent the

bottles from shrinking.

We did not try any peel ply, or heat

shrink tape on the outside for these tests.

We will most likely try that in the future

to remove the excess epoxy and give a

smoother finish. Vacuum bagging is also

something we may consider though that may be

a little tricky.

Tests

WARNING: If you are going to

attempt to reproduce any of these results,

PLEASE pay attention to safety due to the

higher pressures involved. Always conduct

these tests behind a safety barrier and use

eye and ear protection. Make sure your test

equipment is rated for the pressures used.

We tested 4 spliced-pairs of bottles. One

pair used a single wrap of glass on a 90mm

body (there was about 1 inch of overlap),

two used a double wrap on a 90mm body, and

the last used a double wrap on a 110mm body.

The 90mm spliced-pairs hold 2L each and the

110mm spliced-pair holds 3.15L.

We hydrostatically tested these inside an

old scuba tank with the bottom cut off to

contain the noise. We used our high pressure

panel for the tests.

The results:

These results are preliminary and will

need to be repeated a number of times to

confirm their accuracy.

90mm

Spliced Pair

(2L capacity)

|

Splice

Weight (grams) |

Burst

Pressure

(psi / bar) |

Notes |

|

Sikaflex 11FC only |

60 |

~110 / 7.5 |

Failure occurs in the splice as

the glue fails |

Sikaflex 11FC with PL premium

attached sleeve

|

83 |

~180 / 12 |

Here the splice is stronger than

the bottle and the bottle fails. |

|

Sikaflex 11FC with single 200gsm

glass wrap |

135 |

220 / 15 |

Normal bottle failure with glass

torn though |

|

Sikaflex 11FC with double 200gsm

glass wrap |

157 |

300+ / 21+ |

Limit of test equipment reached

without spliced-pair failure.

Two spliced-pairs were tested at

this pressure. |

110mm

Spliced Pair

(3.15L capacity)

|

Splice

Weight (grams) |

Burst

Pressure

(psi / bar) |

Notes |

|

Sikaflex 11FC only |

75 |

~100 / 7 |

Failure occurs in the splice as

the glue fails |

|

Sikaflex 11FC with PL premium

attached sleeve and reinforced

ends using bottle ends held down

with glass strapping tape. |

143

|

~190 / 13 |

Here the splice is stronger than

the bottle and the bottle fails. |

|

Sikaflex 11FC with double 200gsm

glass wrap |

214 |

300+ / 21+ |

Limit of test equipment reached

without spliced-pair failure. |

Conclusions / Observations

- The single glass wrap on a 90mm

spliced-pair was a little disappointing

at 220psi because it means the actual

launch pressure would be closer to

170-180psi.

- The 300psi+ pressure for the double

wrapped bottles was a very good result.

We don't know how much more it can hold,

but the launch pressure would be at

least 250psi. Our high pressure panel

only goes to 300psi so we could not test

to higher pressures. The bottles did not

show any sign of stress when inspected

after the test.

- The 300psi test told us that the

regular bottle caps we use can also hold

at least that much pressure.

- The Sikaflex 11FC alone was able to

provide an air tight seal without

needing the PL premium sleeve to help

hold the splice together.

- Each double wrapped bottle costs

about $4 in glass and glue materials,

which is quite reasonable.

- From the 4.8L of epoxy and hardener

we can make about 100 spliced-pairs of

1.25L bottles, and about 65 of the 2L

bottles.

- The double wrapped 110mm

spliced pair had a 300+ psi burst

pressure. This was a better result than

we had expected.

Simulating performance

Because the reinforced spliced-pairs are

heavier we ran a number of simulations to

see at what point the glass reinforcing is

going to give us better performance over the

lighter but weaker spliced bottles.

We weighed all of the non-pressure vessel

related components from one of our typical

rockets (Axion) which are flown regardless

of the material the pressure vessels are

made of. The total weight of these

components was 380 grams and included,

parachute deployment mechanism, nosecone,

parachute, camera, tornado tubes, nozzle,

fairings and fins.

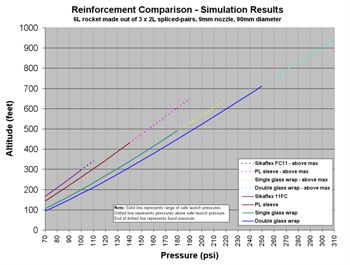

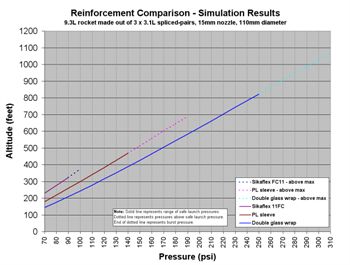

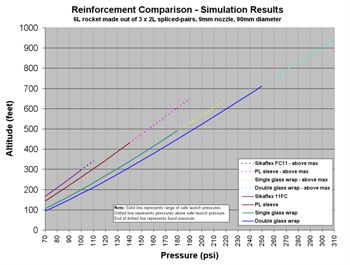

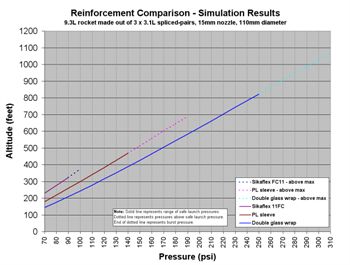

We ran two sets of sims on two different

rockets. One rocket was made of 3 x 90mm

spliced pairs giving a total capacity of 6L

with a 9mm nozzle. The other rocket was

constructed from 3 x 110mm spliced-pairs

giving a total capacity of 9.3L with a 15mm

nozzle. We did not use a launch tube for

either simulation.

We used Clifford's simulator to calculate

the expected altitude in 10psi increments.

In all cases the coefficient of drag was the

same, and we always let the simulator pick

the optimal amount of water for each

pressure. In the graphs below we compare the

4 different 90mm spliced-pairs and their

expected behaviour. The second graph

represents the rockets made out of the

different 110mm spliced-pairs. The solid

lines represent the range of safe launch

pressures, and the dotted line represents

pressures up to the burst pressure. The end

of the dotted line represents the burst

pressure.

Graph 1 - 90mm rocket

performance comparison using different

reinforcement techniques.

Graph 2 - 110mm rocket

performance comparison using different

reinforcement techniques.

Conclusions

In Graph 1 the PL sleeve line represents

the splicing technique we have been using

for most of our rockets. From the graph you

can see that the single glass wrap only

gives modest altitude gains and requires

about 20psi more to break even. However, the

double glass wrap gives significantly higher

altitudes and takes an extra 30psi over the

PL sleeve to break even.

The actual altitudes are only

theoretical, so real world results will

differ.

Similar results were obtained for the

110mm spliced-pairs. I look forward to

launching a 4 x spliced-pair with a long

launch tube. :)

Tornado Tubes

We hydrostatically pressure

tested the tornado tubes to 170psi (before

an non-reinforced bottle connected to it

failed). We'll have a go at building a

rocket using these in upcoming test flights.

We think that they should be able to hold

higher pressures than the 170psi. We'll put

these on the high pressure test panel to see

if they can hold up to the 300psi mark.

More on LiPo batteries

In the last week we have tested the small

70mA LiPo batteries and voltage regulators

with our current flight computers. They seem

to be working well and are nice and compact.

We will test fly these on upcoming flights

to see how well they perform during the

whole launch day.

We also received the 350mAh LiPo

batteries this week and so set about

replacing the batteries inside the FCO's

cameras. The power issues have been a major

reason why we have stopped using them

recently. These batteries are higher

capacity and bigger than the original

batteries and so need to be housed

externally. Due to their higher capacity

they take about 3-4 hours to fully charge

from the USB port. Having waited a full 24

hours after the charge, I did some recording

tests today. This was a test to allow me to

charge the cameras the day before a launch.

I recorded a couple of long movies until

the card was full. After 43 minutes (when I

actually checked) the camera was still on

and was showing that the card was full. It

looks like the new batteries are working

well.

One of these will be placed back in the

Acceleron V booster. With the new battery

the camera now weighs 44 grams compared to

the 39 grams previously.

For charging the little 70mA batteries I

bought a couple of the SparkFun LiPo

chargers. The charger can only charge a

single cell at a time, but having two means

we can be charging two batteries

simultaneously. This is useful when we need

to recharge several battery packs the night

before launch.

Loc/Precision Weasel

Last month I bought a pyro rocket kit

from

Suburban Rocketry that can handle bigger

motors than the ones we have used until now

in Paul's rockets (up to C impulse motors).

This new rocket can take 29mm motors up to G

impulse. Being a kit, construction was quite

simple, although very different to water

rockets of course. I've posted some build

photos on the left. We will most likely fly

it on a E15 first with a 24mm adapter to see

how it flies and then go up from there. It

has a separate payload bay big enough to

carry altimeters or cameras or both, so I'll

look into making use of it in the future. So

far I've painted it white, but still need to

decide if I am going to put any design on it

... and probably should give it a name.

And no, we are not migrating to pyro

rockets, just expanding our knowledge of the

rocketry hobby. :) |