|

Date: 21st September 2008

Location:

Workshop

Conditions:

Pleasant

Team Members at Event:

GK and PK

Test Stand Work

Over the past few weeks we have

been building a sensitive test stand on

which we will be able to test design ideas

and see how they affect performance.

The

last test stand we built was not

sensitive enough to measure the differences

we are interested in. The new stand is based on a single point load-cell

connected to a load cell amplifier and the

amplifier in turn is connected to a data logger.

The guys on the

Forum for Australian Rocketry

were a great help in recommending which

equipment to use, things to look out for,

and generally how to set it up.

Big thanks

goes to Tarp,

PK, PatchleAD, astroboy and others who helped

us get the right

parts and steer us in the right direction. Load Cell

Load cells tend to be quite

expensive, easily upwards of $150-200+. We

had been researching a lot of different

companies and finally found a new 70kg load

cell from a

Chinese manufacturer whose cost

and delivery were far cheaper than local

distributors. We ended up paying

US$24 for it

+ $9 delivery. Delivery was around 8 days.

We chose the 70Kg load cell as it was a good

compromise between the upper and lower

ranges of thrust we want to explore. Data Logger

The data logger we chose was from DATAQ.

We went with the

DI-148U as it already had a

USB connection. My laptop doesn't have a

serial port so I would have needed a serial-to-USB converter anyway. If it did have a

serial port we probably would have gone with

the cheaper

DI-194RS.

We ordered the logger from a local

distributor called

Total Turnkey Solutions (www.turnkey-solutions.com.au).

All up delivered the DI-148U Starter Kit was AU$118. I was very impressed with the

delivery time.

I placed my order just before lunch on

Thursday

and the package from Melbourne was waiting

for me on Friday when I got home from work. Load Cell

Amplifier

The data logger and load cell aren't

enough though, and we also need a load cell

amplifier. The data logger reads in

the -10V to 10V range with a 10-bit accuracy. The load cell only

produces millivolts over the entire

deflection range which is too low for the

data logger to get enough resolution. The

amplifier basically converts these small

voltage changes to a voltage over the full

dynamic range of

the logger. It also provides the necessary

excitation voltage for the load cell.

You can buy these off-the-shelf but you will

pay upwards of $100. Being on a limited

budget, we decided to build our own. The

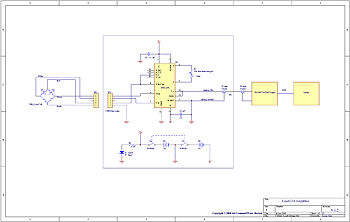

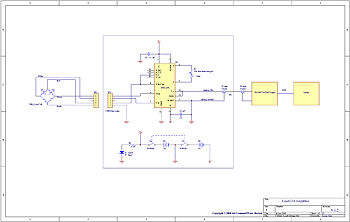

amplifier is based on an

instrument amplifier IC

INA125P. The circuit is

relatively straight forward and these IC's

are designed for exactly this task.

Because it is not easily sourced within Australia, we

ordered them from Texas Instruments in the

US. Circuit Diagram

You can adjust the

amplifier's gain using the multi-turn trim

pot in order to get the

required thrust range. Because we use

two 9V

batteries as the power source we don't quite

get the full +/-10V range, but it is close

enough. The excitation voltage used for the

load cell is 5V. Parts List

Since this was going to be a one-off we

didn't bother with a PCB and just built the

circuit on a strip board.

|

Part |

Designation |

Quantity |

Source |

|

INA 125P Instrument Amp |

U1 |

1 |

Texas

Instruments |

|

16 Pin IC socket |

- |

1 |

Jaycar |

|

50 ohm

Coax Connector |

JP2 |

1 |

Jaycar |

| 5

DIN socket |

JP1 |

1 |

Jaycar |

|

DPDT switch |

S1 |

1 |

Jaycar |

|

Power LED |

LED1 |

1 |

Jaycar |

|

500 Ohm multi turn pot |

R1 |

1 |

Jaycar |

|

1.5KOhm |

R2 |

1 |

Jaycar |

|

0.1uF Capacitor |

C1, C2 |

2 |

Jaycar |

|

9V battery |

B1,B2 |

2 |

Jaycar |

|

9V battery clip |

- |

2 |

Jaycar |

|

Metal enclosure |

- |

1 |

Jaycar |

Software

The data logger came with free "lite"

software for capturing and viewing the data.

However, being free there are some

limitations in terms of exporting the data

and maximum allowed sample rate. The max

sample rate is 240Hz which is more than

ample for us. The full software with higher

allowed sample rates (14,400 samples/sec) is another $200. You

can also buy a $99 software add-on that lets

you save the captured data into Excel

friendly format. (*doh*) The free software, however, does record the

data into their own proprietary binary file

format. I recorded a number of waveforms, and looked at the data in a hex

editor. The data was not encrypted,

so it was relatively easy to

reverse-engineer its format and write a

small program that now allows me to convert their

format into a text .csv file format that is

directly readable by Excel. (saved $99 there

:) )

Preliminary Testing

After initial testing it was discovered

that there was a little bit of noise on the

signal which allowed measurements down to

about 20 grams. One of the guys (PK) on the

Forum for Australian Rocketry made some good suggestions

about how to reduce the signal noise. I

ended up placing the load cell amplifier close to the load

cell and enclosed the whole thing in a metal

box. I also used a coax cable to run the long

lead to the data logger. The noise level

dropped off dramatically. It is now down to

around 0.02V over the -9V to 9V range.

On the 70Kg load cell that allowed me to

resolve down to ~5 grams = a sheet of A4

paper. (Yes I actually put a sheet of

paper on it). This means we can get thrust

measurement accuracy down to about 0.05

Newtons. This hopefully should be good

enough to observe the subtle changes to

components under test. The expected thrust range

of most rockets under test will be about

30N to 150N. That range applies for our

typical rockets with pressures of around

120psi with nozzles under 10mm. The same

setup will also be used for full bore tests

of up to around 600N. Test Stand

At the top of the test stand the load

cell is bolted to a heavy steel plate which

in turn is bolted to the stand. Above that

is the load cell amplifier. The entire

rocket is just suspended from the load cell.

The arrangement at the bottom of the test

stand stops the rocket moving side to side

when thrusting. It consists of 3 adjustable

wheels on ball bearings that allow them to

be brought closer together for narrower

rockets and further apart for wider

rockets. The rocket only lightly touches

these (a few mm clearance) so there is

essentially no friction between them and the

rocket during the test.

The rocket under test can be quickly

disconnected from the load cell with the

single pin that goes through the

bracket connected to the load cell. This

lets us take the rocket off, fill it with

water and re-attach it back to the load

cell.

The release mechanism

consists of a brass Gardena mechanism with

the spring removed and rubber bands are used

to provide a retracting force. We added a

non-return valve inside the release head as

well as a hose quick connect adaptor to the

bottom. We use a thick piece of plastic with

a string attached wedged under the collar.

To release the nozzle we simply pull on the

string and the whole mechanism falls away.

First Tests

We ran 4 thrust tests

yesterday

with different nozzles

on the new test stand. The tests were un-calibrated as we wanted to see what the

overall performance was.

We also set the amplifier

gain for the range

of thrusts we were

interested in.

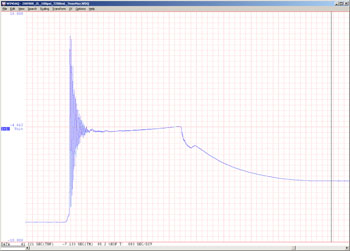

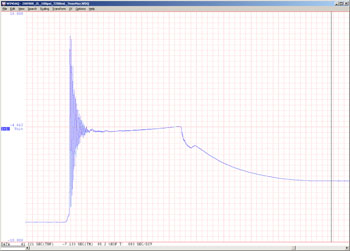

Here is an example of

the raw data captured for both 7mm and 9mm

nozzles at 100psi. There were 2 liters of

water in the 7.2L rocket. Sample rate was

240 Hz.

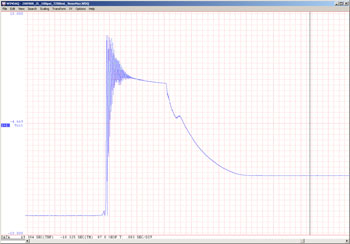

7mm nozzle thrust curve

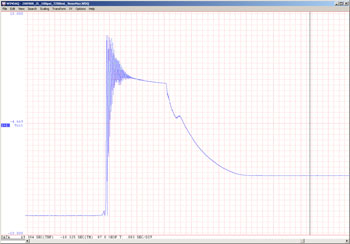

9mm nozzle thrust curve

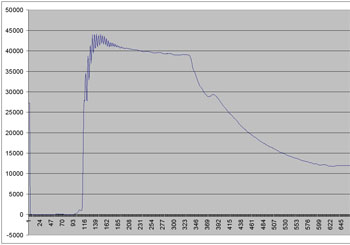

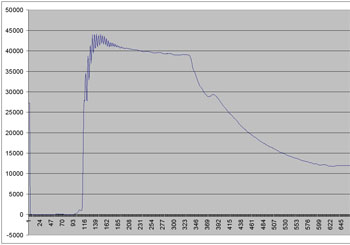

After bringing the data

into Excel, I corrected the offset and ran a

6 sample averaging window on the data to

reduce the ringing seen initially. The data

will be cleaned up further as we incorporate

the linearity curve of the load cell, and

average the data over multiple runs.

9mm nozzle thrust curve

filtered in Excel

The initial ringing is

caused by the initial launch pulse from the

rocket hanging to pushing upwards. It is not

too much of a problem as it can easily be

filtered out. The

pre launch

zero reading

represents the weight of the entire rocket

including water. At the end of the thrust

curve the zero level is higher because the rocket

is lighter. To get the

useful thrust we

essentially draw a horizontal line from the

end level to the start of the thrust curve

and only count what is above that since that

is the actual thrust component that

contributes to the

upward acceleration

of the rocket. The thrust

value under that line is the thrust that

just lifts the rocket off the ground

balancing gravity. The change in weight

of the rocket is non-linear due to the shape

of the bottle and the decreasing pressure.

We will leave data

analysis for another update once everything

is calibrated. In the diagrams above the

thrust can be approximated from the values

as the difference between the initial zero

level and final zero level is the weight of

the water = 2Kg. = 19.6N.

Overall everything went really well and I am

looking forward to doing the actual tests.

The total cost of the test stand not

including the laptop has been about AUD$230.

References

Other sources of load

cells, amplifiers and loggers we looked at:

|