|

Date:

23rd August 2012, 5:00am - 5:30pm

Location: Kurnell, Randwick Race

course, NSW, Australia

Conditions:

20 - 40km/h very windy, warm

25C, partly cloudy in the morning, overcast

and stormy later

Team Members at Event:

PK and

GK

TV Commercial

Last week our rocketry club (NSWRA) was

approached by an advertising agency filming

a TV commercial here in Sydney that involved

a father and son building and launching a

water rocket. They had the actors but needed

some water rockets and a launcher. So we

agreed on a design with a couple of options

that would work for them. In order to

simplify the whole shoot it was decided that

no recovery system would be used. They were

aware that the rocket would be destroyed

after just one flight so they ordered 5 of

them. They were on a tight schedule and we

only had several days to get them all ready.

The design was based on the

Axion II rocket.

Luckily we had enough parts and bottles to

make up the required rockets. I think we ended

up using close to 80 x 1.25L bottles on the

actual rockets and spare parts.

The rockets

Each rocket consisted of 2 spliced pairs

and a single bottle to give a total volume

of around 5.45L. These were coupled together

with normal Tornado tubes with the holes

enlarged and custom washers fitted. The

rockets also had coriflute fins. The

nosecone was just an empty bottle with half

a ping pong ball for the tip. We also taped

an old C- battery onto the top bottle for

extra ballast. These batteries weighed 68

grams. The whole nosecone was just spray

painted red. Initially they asked for the

fins to be painted silver, but the day

before the shoot they asked if they could be

painted red instead and so we re-sprayed

them red. The entire rocket weighed

approximately 450 grams.

We also prepared 3 parachute nosecones

just in case they decided that they wanted

parachutes on the day.

We ended up making 5 rockets + 1 spare.

|

|

|

Paint scheme as originally

requested |

Front view. There is

no recovery system |

Preparing all the rockets a

couple

of nights before. |

|

|

|

Last minute

re-spraying fins. |

Instead of painting we wrapped

the splices with red electrical

tape |

All neatly staked in a box. |

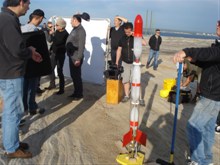

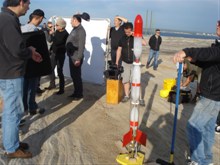

The launcher

Initially they asked to use our old green

launcher, but dad and I also modified our

medium launcher to make it look a little

more home made with a couple of wooden

planks for the base. we also added the guide

rails from our old green launcher so that it

didn't look too complicated. On the day they

decided to use the medium launcher which was

a better choice because it was more stable

than the old launcher especially with the

taller rockets. Normally the small launcher

wouldn't be an issue because we pin it to

the ground with tent pegs, but because they

were shooting on the rocky headland there

was nowhere to hammer the pins in.

|

|

The medium

launcher that

was used for the shoot. |

Here is the

medium launcher

being worked on. |

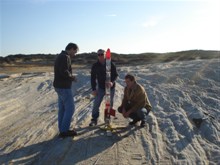

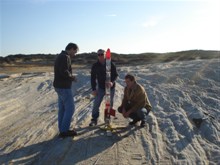

Launch day

This was definitely our earliest start

for a launch to date. We got up just after

3am so we could drive about 1 hour to be on

location by 5am. The nice thing was that

there were no cars on the road at that time.

|

|

|

| 5am Start. It

was pitch black. |

Sunrise on

location

at the headland. |

Waiting for

some other scenes

to be filmed. |

|

|

|

| We started

off with nice blue skies |

but pretty

windy |

getting ready

to set up the rockets |

Due to the location being directly under

the approach flight path to Sydney airport,

we had to restrict the altitude of the

rockets. Since the actors were going to be

close to the rockets anyway we only used

lower pressures.

|

|

|

| Right under

the flight path. |

Dad working

hard as always |

Deciding on

how the scene will work |

The other major problem was the very

strong breeze blowing out to sea. We knew we

may loose a few of the rockets in the ocean.

This really didn't matter as they were one

flight rockets anyway.

|

|

|

| Rocket set up

on the pad |

For quick set up the rockets

were

pre-filled with water and foam. |

Director

deciding how the scene will

play out. |

|

|

|

| One of the

camera men. |

|

Spare rockets

ready for launch |

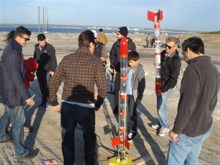

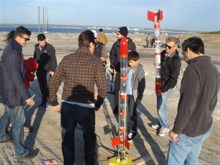

They first did several takes of the

father and son setting up the rocket. After

that they managed to get 2 launches in

before the crew had to move on to another

nearby location. Although there is a foot

pump in the scene, it was never used as it

would have taken too long to pump up the

rockets by hand. We remotely pressurised the

rockets from the scuba tank. The hose was

buried under some sand so you couldn't see

it.

|

|

|

Burying the

hose to the

scuba tank. |

"Father and

son" |

|

|

|

|

|

"Action" |

|

The first rocket flew well and came down

about 30 meters off the edge of the cliff

and on the rocks below. The second rocket

had a similar flight but the wind blew it

further out and it landed in the ocean. One

of the crew managed to retrieve both of them

later when the second one washed up on the

rocks.

We always had to wait with each launch

until there were no planes coming in for a

landing.

|

|

| Remotely

pressurising the rocket |

Waiting until

the plane goes past...

... and launch. |

Then we packed up the gear and headed

back to unit base for lunch (The catering

was awesome!) while they filmed some more

scenes with the father and son getting the

rocket out of a car and arriving at the

launch site. They wanted to get some more

shots of the rockets going up into the sky,

so we set them up at the local park near

where we had lunch, but

weren't sure if they would get through all

their other scenes before filming the

rockets.

|

|

| Lunch with

the crew. |

Waiting at

the local park to see if

they were going to film some

more. |

So after 2 hours of waiting we packed up

and headed to another location at the

Randwick (horse) race course where they were

going to be filming horses racing. They

rented out the whole race track!

We set the rockets up in the middle

of the track ready for filming should they get a

chance. Finally at about 5:00pm they had an

opportunity to film the rockets in flight so we

launched one with foam using the Jet foaming

spacer and a second one without. The light

was fading fast though as a storm was

approaching so I'm not sure if they'll be

able to use that footage or not. Both

rockets flew great and also nicely crumpled

on impact. The wind was still blowing hard

at around 30-40km/h. Way too strong for what

we would normally launch in.

|

|

| Waiting for

the film crew ... |

... as a

storm approaches. |

|

|

| Launch with

jet foaming spacer |

Regular

launch at twilight |

I don't think we will get many more

opportunities to launch our water rockets right in

the middle of the Randwick race course. Just as we

finished packing up the last of the rockets

a huge storm came through with lightning and

even stronger wind so we all went home. It was a

long day, but a lot of fun with a very

friendly crew, and it was good to see

what all goes on behind the scenes of a

commercial shoot.

When the commercial is finished, and if

it's available on line I will post a link to

it here and also mention who the client was.

Servo Timer IIs

We've been busy over the last couple of

weeks soldering up more of the Servo Timer IIs. As we are making these in a greater

quantity this time, we were able to get

better volume discounts on the components so

the timers are a little cheaper than last

time.

If you are interested in using one, they

can be purchased here:

Servo

Timer II

|

|

|

| Components

from Digikey have arrived |

ST II PCBs |

ST IIs ready

for testing |

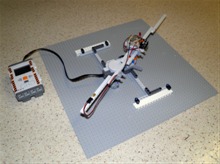

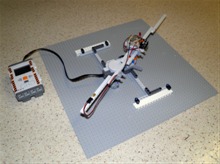

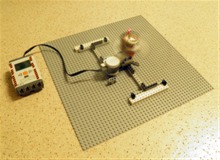

Centrifuge

In testing of the timers we

noticed that some G-switches need more

acceleration than others to activate. The

specification says that they activate

between 2 and 4.9G. 5G may be difficult to

achieve on rockets using small nozzles and

foam or low pressures. So in order to

characterise the G-switches we built a

little centrifuge so we could see at what

G-forces the G-switches actually activate.

The centrifuge was built using the kids Lego Mindstorms NXT

2.0 kit. It made it easy to build

and control the speed of the spinning arm.

The test circuit simply consisted of a 9V

battery an LED and a resistor hooked up to a

socket so we could plug the G-switches into

it easily.

The distance of the G-switch from the center

could also be adjusted to vary the acceleration

force.

We used the high-speed camera to measure

the actual speed of the spinning arm. We

weren't looking for specific activation

force, but more at the relative distribution

of the activation forces for the G-switches

if they were roughly the same or whether

they varied widely.

|

|

Centrifuge for testing G-switch

activation force |

Centrifuge in operation |

Flight Details

| Launch |

Details |

|

Location: Kurnell |

| 1 |

|

Rocket |

|

Axion II |

|

Pressure |

|

80psi |

|

Nozzle |

|

9mm |

|

Water |

|

800mL + foam |

|

Flight Computer |

|

None |

|

Payload |

|

None |

|

Altitude / Time |

|

? / ? |

|

Notes |

|

Good flight with

crash landing as intended. No

recovery system used. |

|

| 2 |

|

Rocket |

|

Axion II |

|

Pressure |

|

80psi |

|

Nozzle |

|

9mm |

|

Water |

|

800mL + foam |

|

Flight Computer |

|

None |

|

Payload |

|

None |

|

Altitude / Time |

|

? / ? |

|

Notes |

|

Good flight with

crash landing as intended. No

recovery system used. |

|

|

Location: Randwick Race Course |

| 3 |

|

Rocket |

|

Axion II |

|

Pressure |

|

100psi |

|

Nozzle |

|

9mm |

|

Water |

|

1000mL + foam |

|

Flight Computer |

|

None |

|

Payload |

|

None |

|

Altitude / Time |

|

? / ? |

|

Notes |

|

Good flight with

crash landing as intended. No

recovery system used. This rocket

had a smaller lowest bottle and

equipped with jet foaming spacer.

Nice slow take-off. |

|

| 4 |

|

Rocket |

|

Axion II |

|

Pressure |

|

90psi |

|

Nozzle |

|

9mm |

|

Water |

|

800mL + foam |

|

Flight Computer |

|

None |

|

Payload |

|

None |

|

Altitude / Time |

|

? / ? |

|

Notes |

|

Good flight with

crash landing as intended. No

recovery system used. |

|

|