|

Date: 27th

November 2010

Location:

Doonside, NSW, Australia

Conditions:

Warm 29C, mostly clear skies

5-20km/h wind.

Team Members at Event:

PK, Paul K and

GK

It's been a fairly quiet month as we have

had many non-rocket related commitments such

as kids birthday parties, sports and school

concerts. Though we have continued to

develop the Polaron G2 nosecone and

recovery system. We also launched a

couple of rockets at the NSWRA launch this

week, but it was more for fun than testing

anything new.

Polaron G2 - Progress

Nosecone

We have continued to try to improve the

nosecone making technique from the last

update. The main problem was trying to

remove the nosecone from the plug without

having to need to split it along the length.

In the second attempt I tried using some

glad wrap on the plug, but I couldn't get

all the wrinkles out, and as a result it

turned out a bit lumpy, especially near the

point. I tried three layers of the 85gsm

cloth, but the end result was that it was

probably too thin to take a bit of

punishment. I had the same trouble getting

the nosecone off the plug as before. I did

try a bias cut on two of the layers

though, and it seemed better to work with.

|

The second attempt did not work

out too well with glad wrap on the

plug. This one is going in the

bin. |

|

For attempt #3 I used a silicone

swimming cap ($7 from BigW)

stretched over the plug and tied

with a string. |

|

This time I used one layer of

the 200gsm cloth and two more layers

of the 85gsm cloth on top. This gave

a very nice finish to the nosecone,

and it was very easy lay over the

swimming cap. Again the bias cut

cloth seemed easier to conform to

the shape. |

|

Because of how the cap stretches

- thin at the point and thick near

the base (~0.8mm), I was hoping that

with the extra thickness around the

base I would be able to stretch the

cap more after the nosecone cured

and hence reduce the lining diameter

giving that important gap to

separate.

I trimmed the excess glass from

around the base and then slowly

worked my way around stretching the

cap and you could see it separate

between the nosecone and cap. This

propagated almost 3/4 of the way

from the base to the nose and was

easy to do. Unfortunately when

trimming the glass I nicked the cap

in a couple of places so I ended up

ripping holes in it. But that was

enough to quite easily pull the

nosecone off the plug.

So here is one clean nosecone, and

the finer weave on the outside

should make this one easier to

finish off the surface. I am tempted

to stretch another cap over the

outside when I lay it up which may

give it a nice smooth finish, but

air bubbles might be a problem. |

|

I also didn't use a black marker

on the pattern this time which

should stop it from bleeding through

when painting. |

Recovery System

The recovery technique we are using for

G2 is similar to the in-line one we

trialled earlier this

year with several improvements and in larger

scale. This first version is still a

prototype so it is a little heavier than

we'd like, but good enough for first

flights.

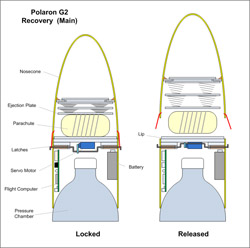

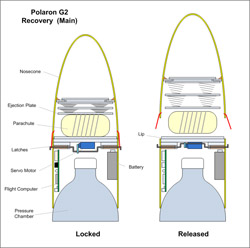

How it works:

The parachute is simply packed and placed

on top of the flat platform on the base. The

nosecone has a spring loaded ejection plate

inside it. When you put the nosecone on top

of the parachute you compress the ejection

plate and then lock down the nosecone on

either side with latches.

The nosecone side of the latch is simply

a rubber band made from an o-ring so

it stretches less. The base latch pivots so

that the loop is caught and held down.

click image to zoom in

When it's time to release the parachute,

the base latch pivots back so that the loops

on both sides slip off and the nosecone and

parachute are free to fall/slide off. The

springs ensure there is enough force to just

separate them and the uneven airflow does

the rest. The springs should be strong

enough to overcome the air pressure on the

nose. In the final full recovery system,

there will be a separate drogue parachute

mounted in the mid section of the rocket,

and will be triggered by PK's MAD. This will

cause the rocket to come down sideways (more

drag) and so when it later comes to

deploying the main, the airflow over the

nosecone will be sideways and hence even

easier to deploy the main parachute.

|

Some of the components that make

up the deployment mechanism. We

didn't end up using the two clear

rings in the photo as we changed the

design. The fairing for the base is

made from two layers of 200gsm

fiberglass. |

|

We made a couple of inserts to

go into the Coreflute to support the

crank shaft. |

|

Servo motor with crank and

latches. This way we release both

latches at the same time. |

|

Ejection plate components are

made from 5mm Corflute. |

|

The ejection plate locks into a

slot inside the nosecone. This

allows us to replace the ejection

plate for different sized

parachutes. We use conical springs

which compress down well. (Looking

into nosecone on the right) |

|

The base has a smooth top

without any obstructions to allow

the parachute to easily slide off in

the air flow. There is a small lip

around the outside which fits inside

the inner edge of the nosecone. This

keeps the nosecone from sliding

around sideways when in the locked

position. |

|

Looking into the base. The

components are spread out around so

that we can fit a part of the

pressure chamber in the space in the

middle. |

|

Nosecone, base with parachute on

top and the ejection plate. |

|

Latch in the open position. |

|

Latch in the closed position. |

|

An O-ring is used as the rubber

band to catch onto the latch. |

|

Overall nosecone and deployment

mechanism. |

Launch Day Report

Due to all the commitments we had during

the week, we only packed the sustainer from

the Acceleron V rocket and a few spare

rocket components so that we could make one

up on the spot should the rocket crash. The

predictions were for high wind on the day,

so we weren't sure what we should fly

anyway. It turned out to be a nice day and

the wind was fairly calm during the morning.

We flew the first flight at 125psi with

1.8L of water and foam. The flight was good

with good recovery. The on-board video is

shown in the highlights video below. Because

the wind direction was towards the rocket

eating trees I decided to take out the

altimeter in case the rocket got snagged.

As the wind picked up a little for the

second flight, I removed the camera again

because of the danger of getting snagged in

the tree. We also added an extra second to

the deployment timer to help the rocket come

down quicker. The flight was good again with

a nice long foam trail.

For the last flight, I swapped out the

bigger parachute for a smaller one with a

hole, again to try to stop the rocket

drifting too far. Again the flight was

virtually identical to the previous flights

and the rocket ended up landing fairly close

to the trees.

We also flew Paul's Pod 2 2-stage rocket

on a C6-0 and a C6-5. The rocket weather

cocked into the wind and flew in a nice long

arc. The stages separated well, but the

delay seemed a bit long and when the

parachute finally deployed it ended up

ripping a fin off the rocket. We couldn't

find the fin in the tall grass, but it

should be fairly easy to repair.

We were happy the water rockets performed

well and it's always nice to get them back

in one piece.

We wanted to test fly the G2 nosecone but

ran out of time during the week to prepare

the test rocket, there is always next time.

In the video below I have combined both the

pyro rockets and water rockets flown by club

members at the NSWRA launch at Doonside.

Day 98 - Highlights

Flight Details

| Launch |

Details |

| 1 |

|

Rocket |

|

Axion VII |

|

Pressure |

|

125 psi |

|

Nozzle |

|

9mm |

|

Water |

|

1.8L + foam |

|

Flight Computer |

|

V1.6 - 5 seconds |

|

Payload |

|

MD-80 clone camera x 1 |

|

Altitude / Time |

|

? / ? seconds |

|

Notes |

|

Good flight with

good parachute deploy. Rocket landed

well. Good onboard video. |

|

| 2 |

|

Rocket |

|

Axion VII |

|

Pressure |

|

125 psi |

|

Nozzle |

|

9mm |

|

Water |

|

1.8L + foam |

|

Flight Computer |

|

V1.6 - 6 seconds |

|

Payload |

|

None |

|

Altitude / Time |

|

? / ? seconds |

|

Notes |

|

Good flight with

deploy past apogee. Slow takeoff

again. No camera was on this flight.

Delay added to open parachute later

in flight. |

|

| 3 |

|

Rocket |

|

Pod 2 (Paul's Praetor) |

|

Motor |

|

C6-0 and C6-5 |

|

Altitude / Time |

|

? / ? |

|

Notes |

|

Good flight, but

weather cocked into the wind.

Staging was nominal and the parachute ejected well after

apogee. Ejection event broke a fin

off the rocket. |

|

| 4 |

|

Rocket |

|

Axion VII |

|

Pressure |

|

125 psi |

|

Nozzle |

|

9mm |

|

Water |

|

1.8L + foam |

|

Flight Computer |

|

V1.6 - 6 seconds |

|

Payload |

|

None |

|

Altitude / Time |

|

? / ? seconds |

|

Notes |

|

Good flight with

slow takeoff. We used the smaller

white parachute for this flight to

stop it drifting too far. Good

landing. |

|

|